Coated granatohedron tungsten-tungsten carbide composite material and preparation method thereof

A rhomboid dodecahedron and composite material technology, applied in the field of coated ultrafine tungsten carbide-tungsten particles and its preparation, to achieve the effect of promoting self-assembly arrangement, simple process control, and expanding application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

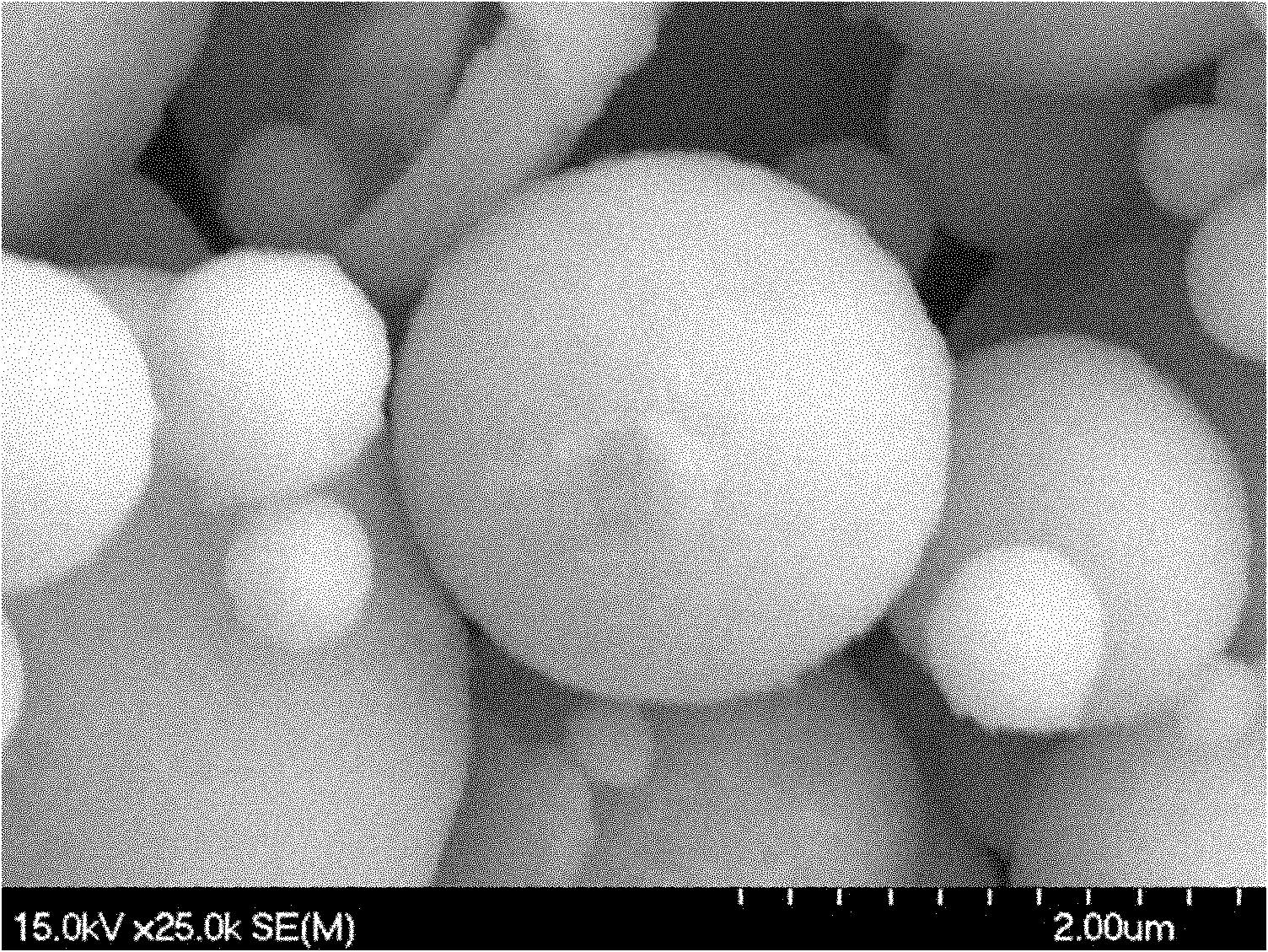

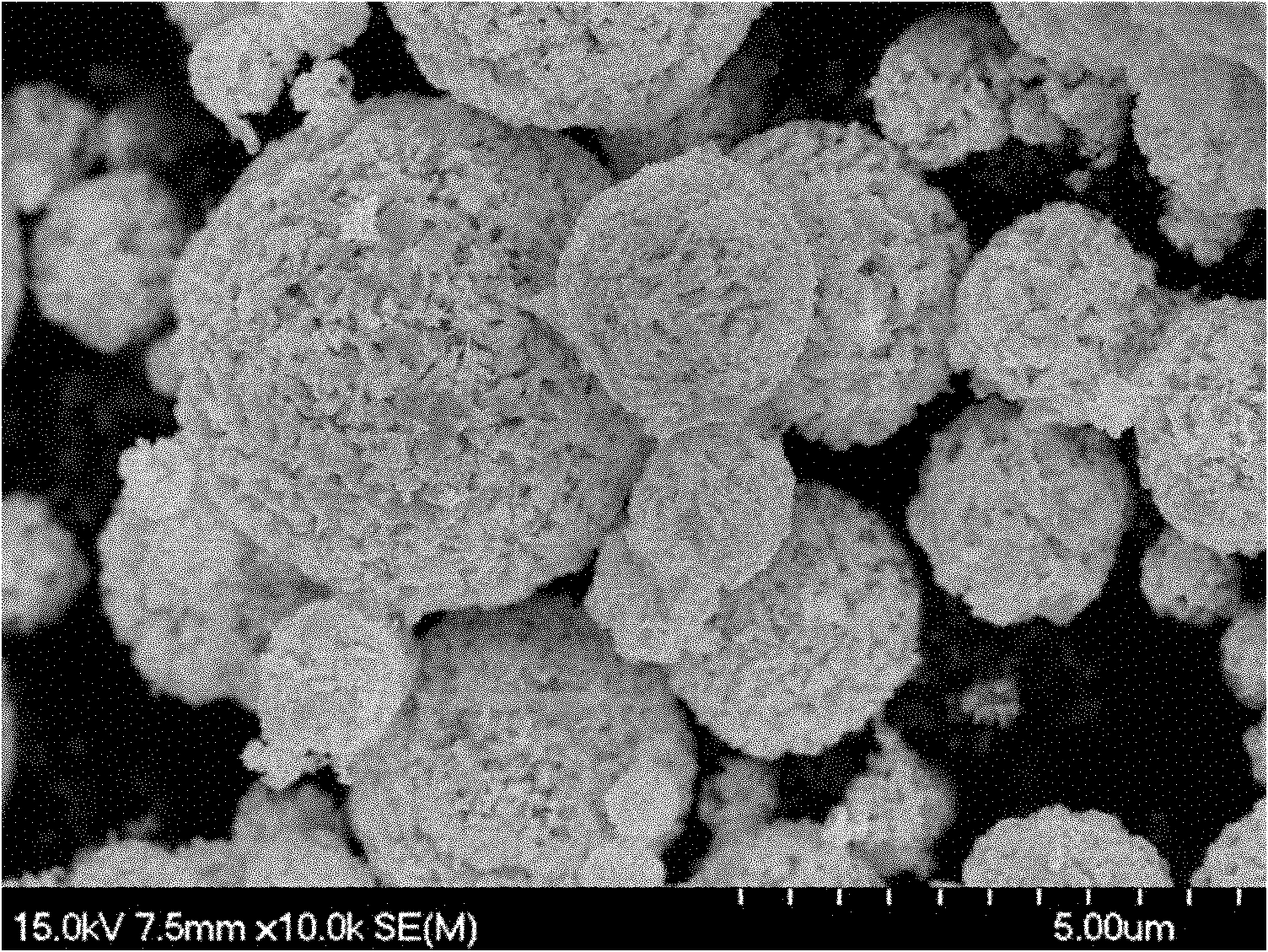

[0031]Dissolve ammonium metatungstate in water to prepare a 15wt% solution, and oscillate ultrasonically for 30 minutes at room temperature; while stirring with a magnetic stirrer, introduce the solution into a spray dryer for spray drying. The spray drying conditions are: feed liquid The inlet flow rate is 30mL / min, the air inlet flow rate is 10L / min, the inlet temperature of the air nozzle is 180°C, and the temperature at the outlet of the tail gas is 90-100°C to obtain spherical ammonium metatungstate particle precursor; the dried precursor Put the body into a quartz boat and place it in a tube furnace. After passing through a 50°C water bath, the mixed gas of carbon monoxide and carbon dioxide is passed into the tube furnace for reduction carbonization. The temperature is raised to 900°C according to the 2°C / min program. The ratio is 9:1, the mixed gas flow rate is 300mL / min, and the reduction carbonization time is 12 hours. After the reaction was completed, the product wa...

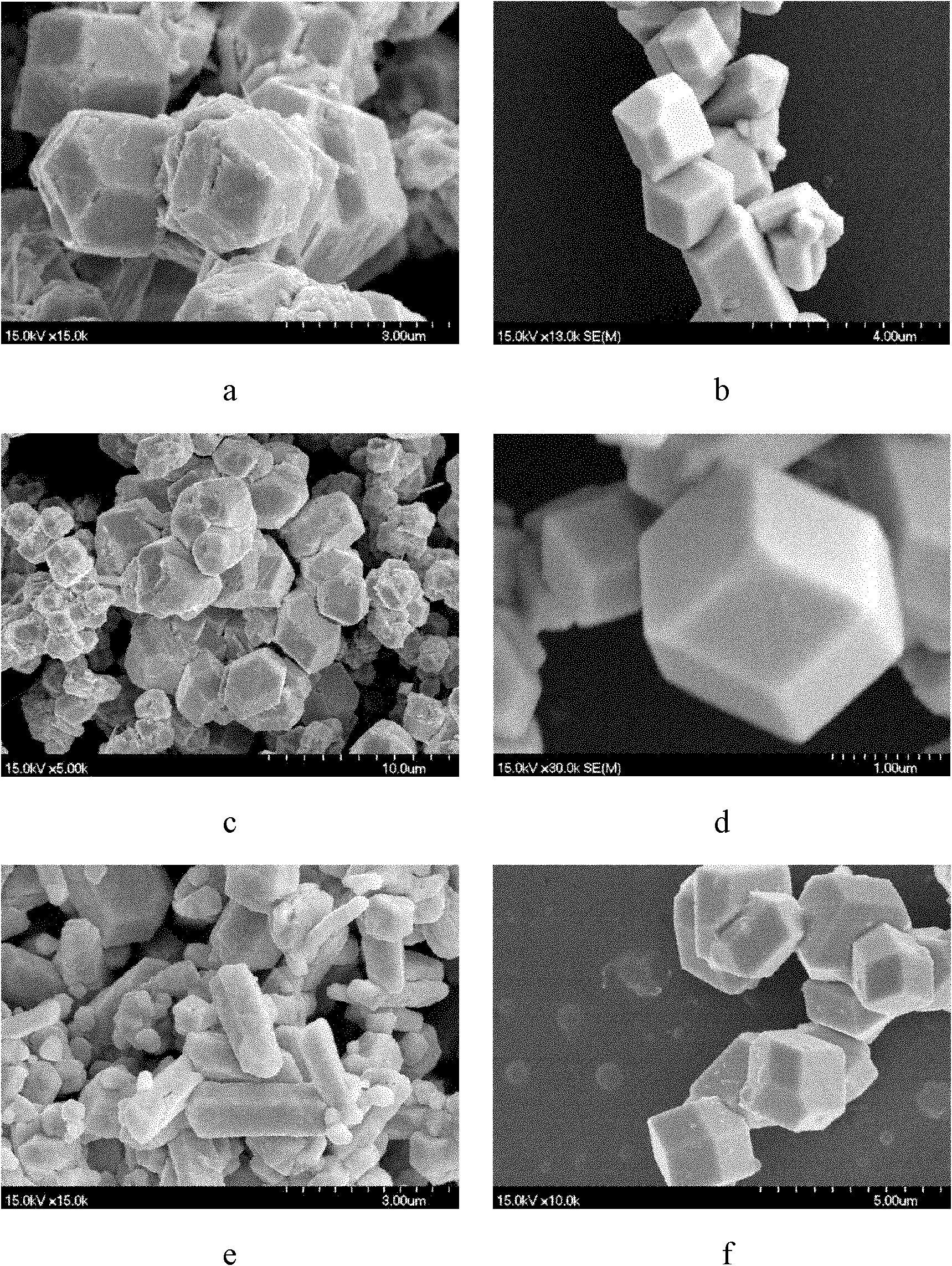

Embodiment 2

[0033] Dissolve ammonium metatungstate in water to prepare a 15wt% solution, and oscillate ultrasonically for 30 minutes at room temperature; while stirring with a magnetic stirrer, introduce the solution into a spray dryer for spray drying. The spray drying conditions are: feed liquid The inlet flow rate is 30mL / min, the air inlet flow rate is 10L / min, the inlet temperature of the air nozzle is 180°C, and the temperature at the outlet of the tail gas is 90-100°C to obtain spherical ammonium metatungstate particle precursor; the dried precursor Put the body into a quartz boat and place it in a tube furnace, pass the mixed gas of carbon monoxide and carbon dioxide through a 20°C water bath, then pass it into the tube furnace for reduction carbonization, and increase the temperature to 800°C according to the 4°C / min program. The ratio is 3:1, the mixed gas flow rate is 300mL / min, and the reduction carbonization time is 9 hours. After the reaction was completed, the product was c...

Embodiment 3

[0035] Dissolve ammonium metatungstate in water to prepare a 15wt% solution, and oscillate ultrasonically for 30 minutes at room temperature; while stirring with a magnetic stirrer, introduce the solution into a spray dryer for spray drying. The spray drying conditions are: feed liquid The inlet flow rate is 30mL / min, the air inlet flow rate is 10L / min, the inlet temperature of the air nozzle is 180°C, and the temperature at the outlet of the tail gas is 90-100°C to obtain spherical ammonium metatungstate particle precursor; the dried precursor Put the body into a quartz boat and place it in a tube furnace. After the mixed gas of methane and hydrogen passes through a 30°C water bath, it is passed into the tube furnace for reduction and carbonization. The temperature is raised to 800°C according to the 2°C / min program. The ratio is 18:1, the mixed gas flow rate is 220mL / min, and the reduction carbonization time is 10 hours. After completion of the reaction, the product was cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com