Gel electrolyte in dye-sensitized solar cell, special electrolyte and preparation method thereof

A technology of electrolyte and liquid electrolyte, which is applied in the field of dye-sensitized solar cells, can solve the problems of hindering redox electricity and reducing the photoelectric conversion efficiency of the battery, and achieve good photoelectric conversion efficiency, improved stability, and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The components and moles are respectively elemental iodine 0.1mol, lithium iodide 0.1mol, N-methylbenzimidazole 0.45mol, 1,2-dimethyl-3-propylimidazole iodide salt 0.6mol, and the solvent is formazan In the liquid electrolyte of oxypropionitrile (amount of 1 L), 2.5% of the total mass of the liquid electrolyte was added with PEO having a molecular weight of 2.0×10 6 g / mol. Under stirring and sealing conditions, heat the gelling agent PEO and the liquid electrolyte to about 60°C. After the PEO gels, heat at 70-80°C for 48 hours to obtain the gel electrolyte provided by the present invention.

[0028] Dye-sensitized cells were prepared according to the following general method:

[0029] 1) Preparation of photoanode

[0030] This step is prepared according to the method provided by the following documents:

[0031] Self-Organization of TiO 2 Nanoparticles in Thin Films, S.D.Burnside, V.Shklover, C.Barbé, P.Comte, F.Arendse, K.Brooks, M. Chemistry of Materials, 10 (19...

Embodiment 2

[0037] The components and moles are respectively elemental iodine 0.1mol, lithium iodide 0.1mol, N-methylbenzimidazole 0.45mol, 1,2-dimethyl-3-propylimidazole iodide salt 0.6mol, and the solvent is formazan In the liquid electrolyte of oxypropionitrile (amount of 1L), add 5.0% of the total mass of liquid electrolyte with a molecular weight of 2.0×10 6 g / mol of PEO. Under the condition of stirring and sealing, the temperature of the gelling agent PEO and the above-mentioned liquid electrolyte was raised to 60°C, and after the PEO was gelled, it was heated at 70-80°C for 48 hours to obtain the gel electrolyte provided by the present invention.

[0038] The dye-sensitized solar cell was assembled according to the same method and preparation conditions as in Example 1, wherein the electrolyte used was the liquid electrolyte provided in this example.

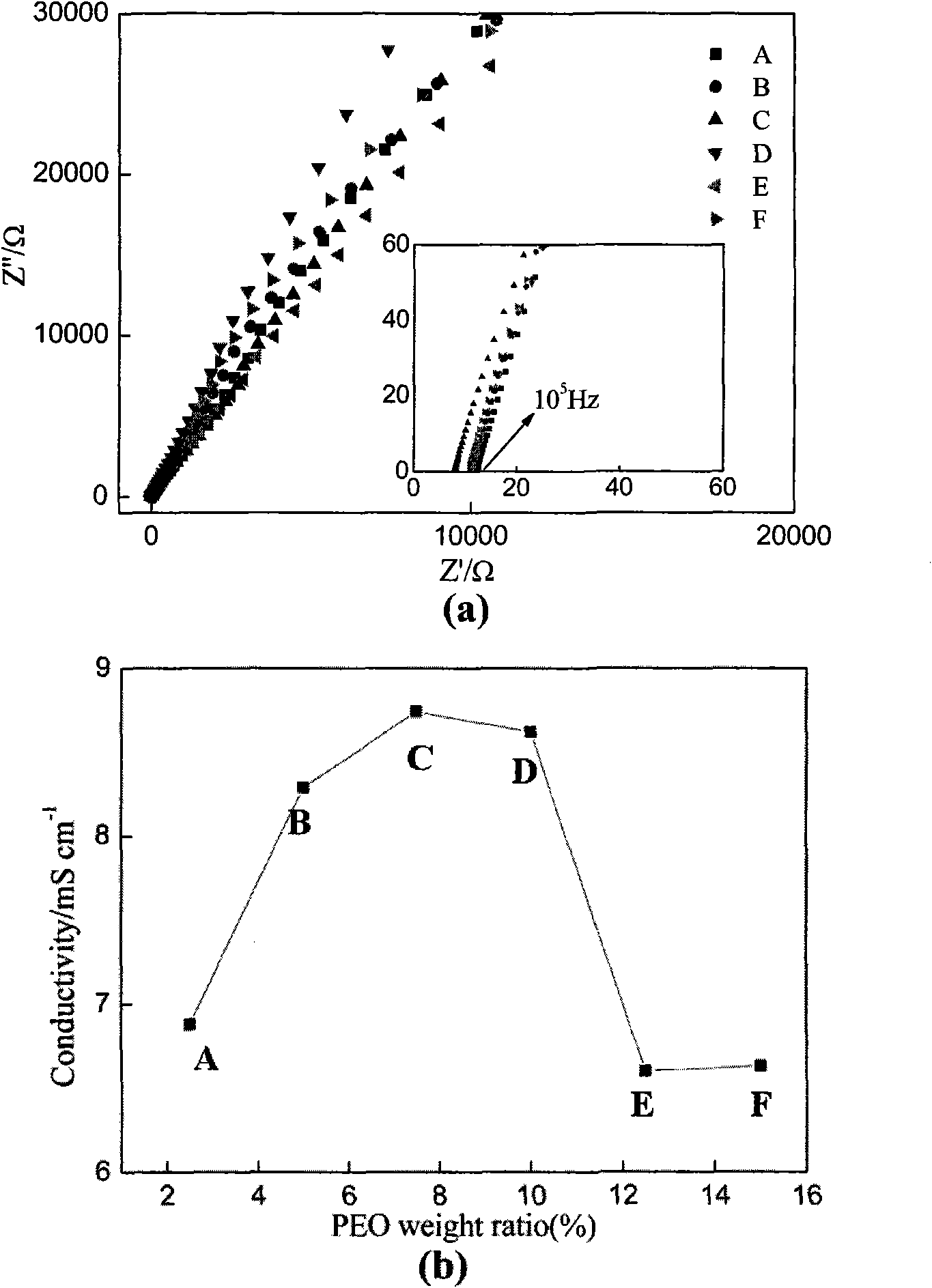

[0039] Use CHI660 Electrochemical Workstation to test the AC impedance of the electrolyte, such as figure 1 (b), and further obta...

Embodiment 3

[0041] The components and moles are respectively elemental iodine 0.1mol, lithium iodide 0.1mol, N-methylbenzimidazole 0.45mol, 1,2-dimethyl-3-propylimidazole iodide salt 0.6mol, and the solvent is formazan In the liquid electrolyte of oxypropionitrile (amount of 1L), add 7.5% of the total mass of liquid electrolyte with a molecular weight of 2.0×10 6 g / mol of PEO. Under the condition of stirring and sealing, the temperature of the gelling agent PEO and the above-mentioned liquid electrolyte was raised to 60°C, and after the PEO was gelled, it was heated at 70-80°C for 48 hours to obtain the gel electrolyte provided by the present invention. The dye-sensitized solar cell was assembled according to the same method and preparation conditions as in Example 1, wherein the electrolyte used was the liquid electrolyte provided in this example.

[0042] Use CHI660 Electrochemical Workstation to test the AC impedance of the electrolyte, such as figure 1 (a), and further obtain the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Short circuit current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com