Method for preparing silicon carbide composite particles and application thereof as cathode material of lithium ion battery

A silicon-carbon composite and particle technology, used in battery electrodes, circuits, electrical components, etc., can solve problems such as poor material uniformity, poor silicon dispersion, and poor silicon-carbon interface contact, and achieve poor cyclability and practicality. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

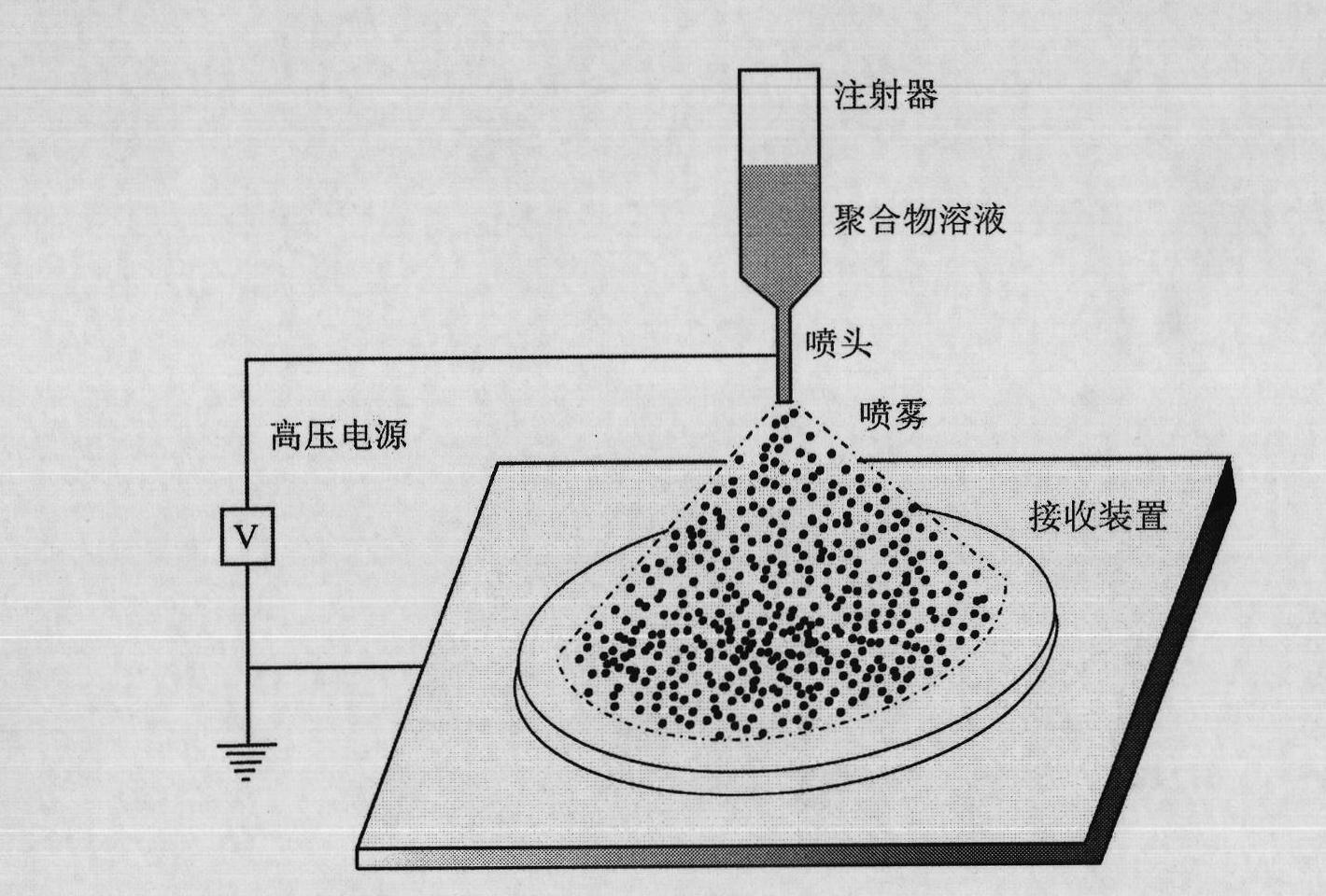

[0032] Example 1. Preparation of silicon-carbon composite particles and its electrochemical performance test

[0033] Press chitosan (weight-average molecular weight is 89000): the mass ratio of silicon quantum dots=50: 0.1 mixes, with water as solvent, stirs at room temperature more than 24h, obtains the mass concentration sum of chitosan and silicon quantum dots as 1% solution. Inject the polymer solution into the syringe of the electrostatic jet device, the nozzle is 20cm away from the collecting plate, and the voltage is 150kV, carry out electrostatic spraying, and the obtained particles are raised from room temperature to 800°C at a rate of 10°C / min under the protection of nitrogen, and the temperature is constant After 6 hours, it was naturally cooled to room temperature to obtain silicon-carbon composite particles.

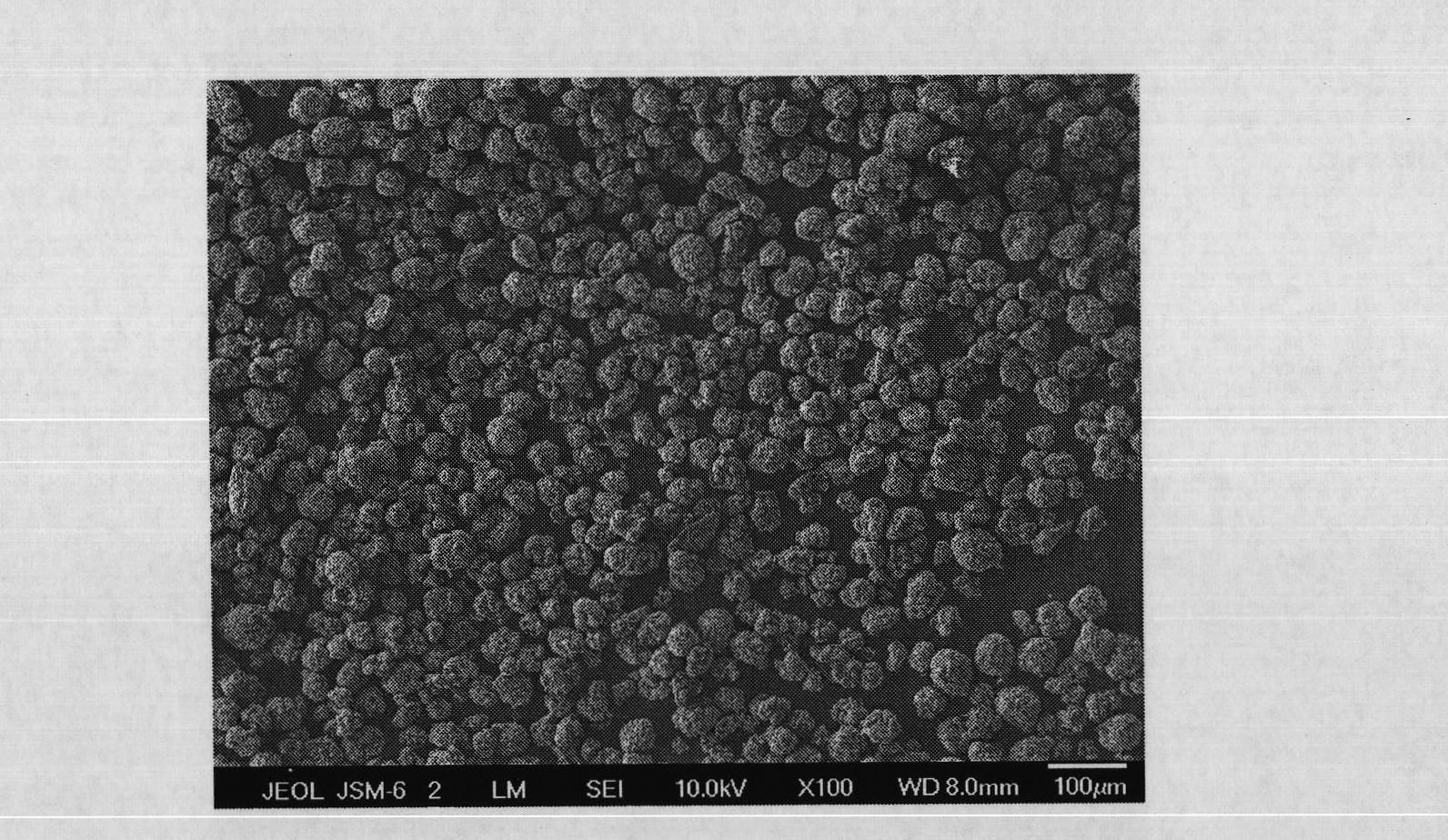

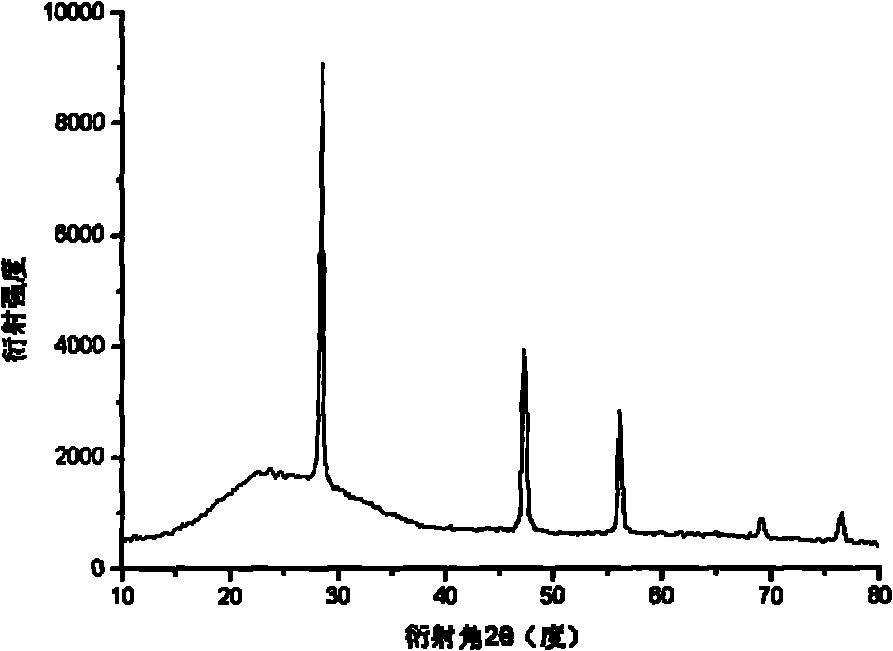

[0034] Characterization of Silicon Carbon Composite Particles:

[0035] The particle size and particle size distribution of the silicon-carbon composite ...

Embodiment 2

[0040] Example 2. Preparation of silicon-carbon composite particles and its electrochemical performance test

[0041] Mix by mass ratio of chitosan (weight average molecular weight is 89000): silicon powder=20: 0.1, take water as solvent, stir at room temperature more than 24h, the mass concentration sum that obtains chitosan and silicon powder is 5% The solution. Inject the polymer solution into the syringe of the electrostatic jet device, the nozzle is 20cm away from the collecting plate, the high voltage is 150kV, and the electrostatic spray is carried out. After 6 hours, the temperature was lowered to room temperature at a rate of 10°C / min to obtain silicon-carbon composite particles.

[0042] The positive electrode, negative electrode, electrolyte and battery assembly of the simulated battery are the same as in Example 1. The composition of the obtained silicon-carbon composite particles and the test results in the simulated battery are listed in Table 1.

Embodiment 3

[0043] Example 3, Preparation of Silicon Carbon Composite Particles and Testing of Their Electrochemical Properties

[0044] Mix by sodium carboxymethyl cellulose (weight average molecular weight is 250000): the ratio (mass ratio) of silicon monoxide=1: 0.1, take water as solvent, stir at room temperature more than 24h, obtain sodium carboxymethyl cellulose and The sum of the mass concentrations of silicon monoxide is 50% solution. Inject the polymer solution into the syringe of the electrostatic jet device, the nozzle is 20cm away from the collecting plate, the high voltage is 150kV, and the electrostatic spray is carried out. After 6 hours, it was naturally cooled to room temperature to obtain silicon-carbon composite particles.

[0045] The positive electrode, negative electrode, electrolyte and battery assembly of the simulated battery are the same as in Example 1. The composition of the obtained silicon-carbon composite particles and the test results in the simulated bat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com