Curable electromagnetic shielding adhesive film, method for producing the same, use of the same, method for producing electromagnetic shielding article, and electromagnetic shielding article

A curing and shielding technology, applied in the direction of conductive adhesives, magnetic field/electric field shielding, chemical instruments and methods, etc., can solve the problems of reduced conductivity and inability to adapt to bending resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

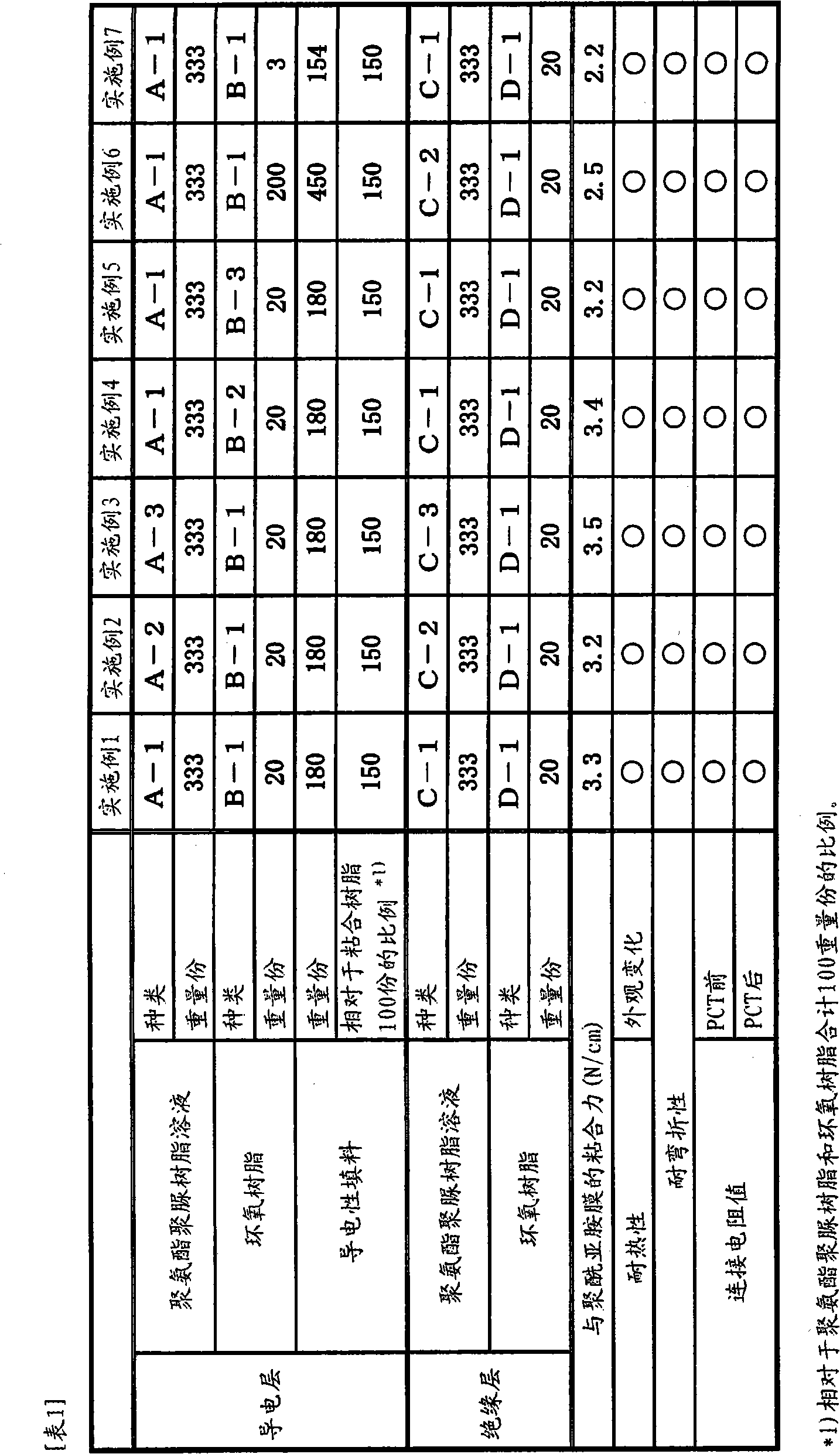

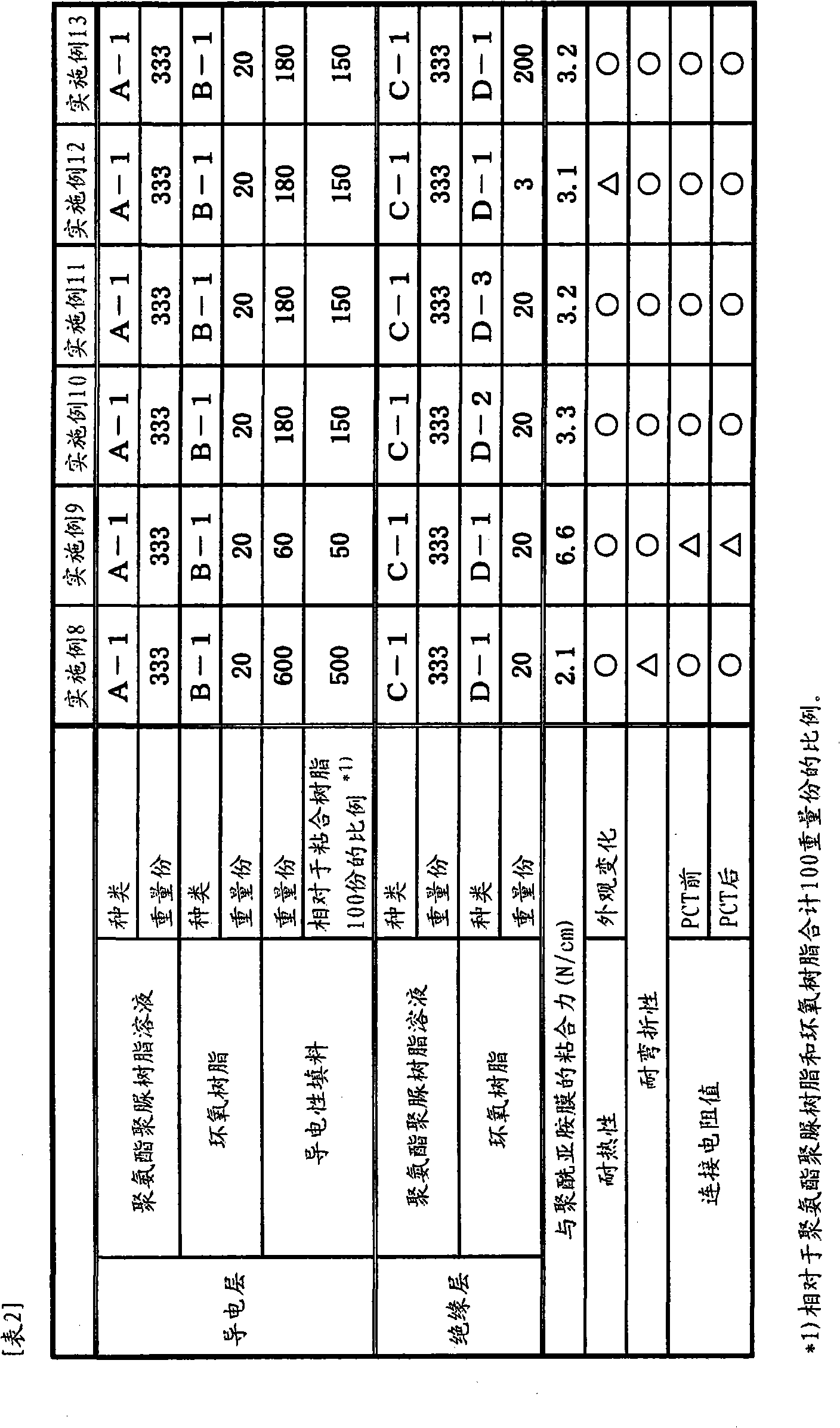

[0297] Next, the present invention will be described in more detail with reference to examples, but the present invention is not limited to these examples. In Examples and Comparative Examples, "parts" and "%" mean "parts by weight" and "% by weight", respectively.

[0298] In addition, the weight-average molecular weight of the polyurethane polyurea resin and the number-average molecular weight of the polyester resin described in the examples are weight-average molecular weight and number-average molecular weight in terms of polystyrene obtained by GPC measurement, and the conditions for GPC measurement are as follows .

[0299] Device: Shodex GPC System-21 (manufactured by Showa Denko)

[0300] Chromatographic column: Shodex KF-802, KF-803L, KF-805L

[0301] (manufactured by Showa Denko) A total of 3 connections are used.

[0302] Solvent: THF

[0303] Flow rate: 1.0mL / min

[0304] Temperature: 40°C

[0305] Sample concentration: 0.3% by weight

[0306] Sample injecti...

Synthetic example 1

[0309] In a reaction vessel with a stirrer, thermometer, reflux condenser, dropping device and nitrogen introduction tube, the number average molecular weight obtained from adipic acid, terephthalic acid and 3-methyl-1,5-pentanediol was charged (hereinafter referred to as "Mn")=1006 diol 414 parts, dimethylol butyric acid 8 parts, isophorone diisocyanate 145 parts, and toluene 40 parts, reacted at 90 degreeC under nitrogen atmosphere for 3 hours. 300 parts of toluene was added thereto, and the solution of the polyurethane prepolymer which has an isocyanate group at the terminal was obtained. Next, to a mixture of 27 parts of isophoronediamine, 3 parts of di-n-butylamine, 342 parts of 2-propanol, and 576 parts of toluene, 816 parts of the solution of the obtained polyurethane prepolymer were added and reacted at 70°C. After 3 hours, a polyurethane polyurea resin solution having a weight average molecular weight (hereinafter referred to as "Mw") = 54,000 and an acid value of 5 m...

Synthetic example 2

[0311] In a reaction vessel with a stirrer, a thermometer, a reflux condenser, a dropping device and a nitrogen introduction tube, a mixture of adipic acid, 3-methyl-1,5-pentanediol and 1,6-hexane carbonate diol was charged. (1,6-ヘキサンカ-ボネ-トジオル) obtained 390 parts of diols with Mn=981, 16 parts of dimethylol butyric acid, 158 parts of isophorone diisocyanate and 40 parts of toluene, under a nitrogen atmosphere React at 90°C for 3 hours. 300 parts of toluene was added thereto, and the solution of the polyurethane prepolymer which has an isocyanate group at the terminal was obtained. Next, to a mixture of 29 parts of isophorone diamine, 3 parts of di-n-butylamine, 342 parts of 2-propanol, and 576 parts of toluene, 814 parts of the obtained polyurethane prepolymer solution were added and reacted at 70°C for 3 hours , to obtain a solution of polyurethane polyurea resin with Mw=43,000 and acid value of 10 mgKOH / g. 144 parts of toluene and 72 parts of 2-propanol were added thereto ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com