Food grade phycocyanin and preparation method thereof

A phycocyanin, food-grade technology, applied in the field of separation and purification of phycocyanin, can solve the problems of restricting the popularization and use of spirulina phycocyanin products, high price of phycocyanin, inability to prepare in large quantities, etc. The effect of low production cost and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

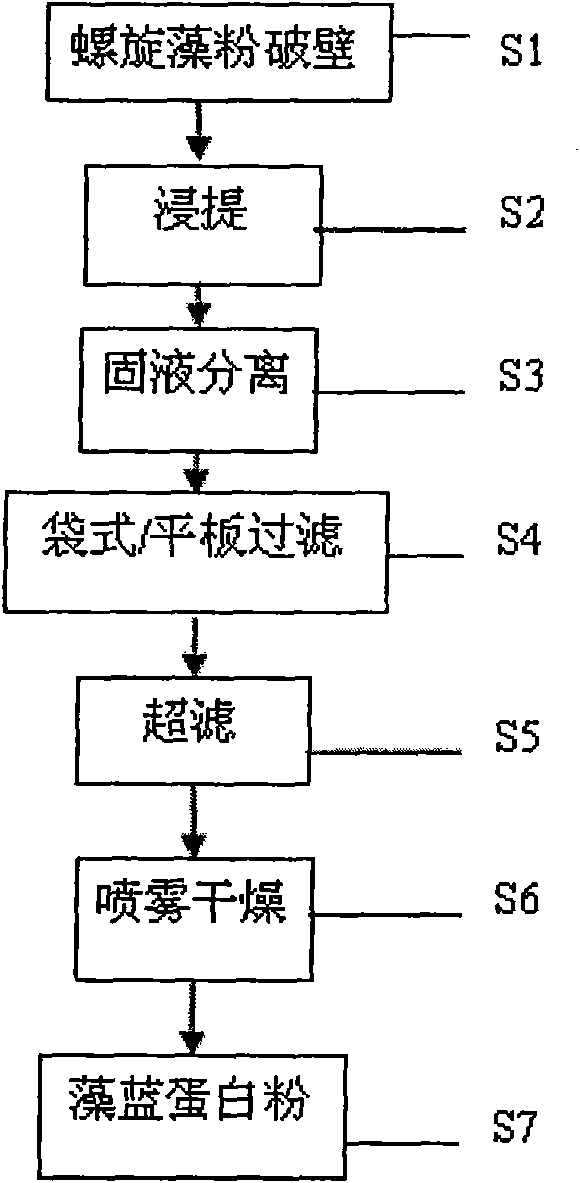

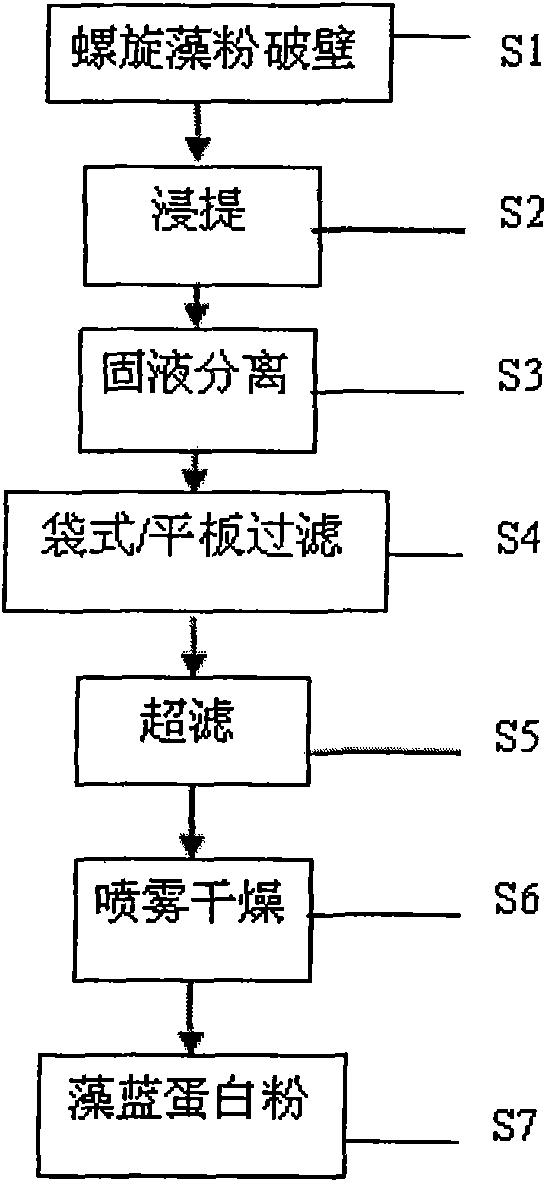

[0028] The preparation method steps of food grade phycocyanin are as follows:

[0029] (1) Take 5 kg of spirulina powder, put the prepared 4°C equivalent phosphate buffer into the mixing granulator, adjust the time relay, set the wet mixing time to 3 minutes, and turn on the stirring motor and the chopping motor , set the stirring blade speed as I speed, and the chopping knife speed as II speed for wet mixing. After the wet mixing is completed, open the discharge piston, turn on the stirring paddle, and discharge the material. Use a 16-mesh nylon mesh oscillating granulator to make spirulina wet granules, and then use a colloid mill to grind the spirulina wet granules circularly and pulverize them fully. During grinding, the temperature does not exceed 4 °C.

[0030] (2) Add 25 liters of 0.01-0.05M, pH6.0-7.0 phosphate buffer solution to the spirulina powder ground by the colloid mill, and place it in a freezer for extraction for more than 8 hours;

[0031] (3) The leaching ...

Embodiment 2

[0037] The preparation method steps of food grade phycocyanin are as follows:

[0038] (1) Take 10 kg of spirulina powder, put the prepared 4°C equivalent phosphate buffer into the mixing granulator, adjust the time relay, set the wet mixing time to 3 minutes, and turn on the stirring motor and the chopping motor , set the stirring blade speed as I speed, and the chopping knife speed as II speed for wet mixing. After the wet mixing is completed, open the discharge piston, turn on the stirring paddle, discharge the material, use a 16-mesh nylon mesh oscillating granulator to make wet spirulina granules, and then grind the wet spirulina granules circularly with a colloid mill to fully pulverize. During grinding, the temperature does not exceed 4 °C.

[0039] (2) Add 50 liters of 0.01-0.05M, pH6.0-7.0 phosphate buffer solution to the spirulina powder ground by the colloid mill, and place it in a freezer for extraction for more than 8 hours;

[0040] (3) The leaching solution is...

Embodiment 3

[0046] The steps of the food grade phycocyanin preparation method are as follows:

[0047] (1) Take 15 kg of spirulina powder, put the prepared 4°C equivalent phosphate buffer into the mixing granulator, adjust the time relay, set the wet mixing time to 3 minutes, and turn on the stirring motor and the chopping motor , set the stirring blade speed as I speed, and the chopping knife speed as II speed for wet mixing. After the wet mixing is completed, open the discharge piston, turn on the stirring paddle, and discharge the material. Use a 5-mesh nylon mesh oscillating granulator to make spirulina wet granules, and then use a colloid mill to grind the spirulina wet granules circularly and fully pulverize. During grinding, the temperature does not exceed 4 °C.

[0048] (2) Add 75 liters of 0.01-0.05M, pH6.0-7.0 phosphate buffer solution to the spirulina powder ground by the colloid mill, and place it in a freezer for extraction for more than 8 hours;

[0049] (3) The leaching s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com