Glass mould material of alloy cast iron and preparation method thereof

A technology of glass mold material and alloy cast iron, which is applied in the field of preparation of alloy cast iron glass mold material and alloy cast iron glass mold material. Machinability, improved heat dissipation, and effect of ensuring heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

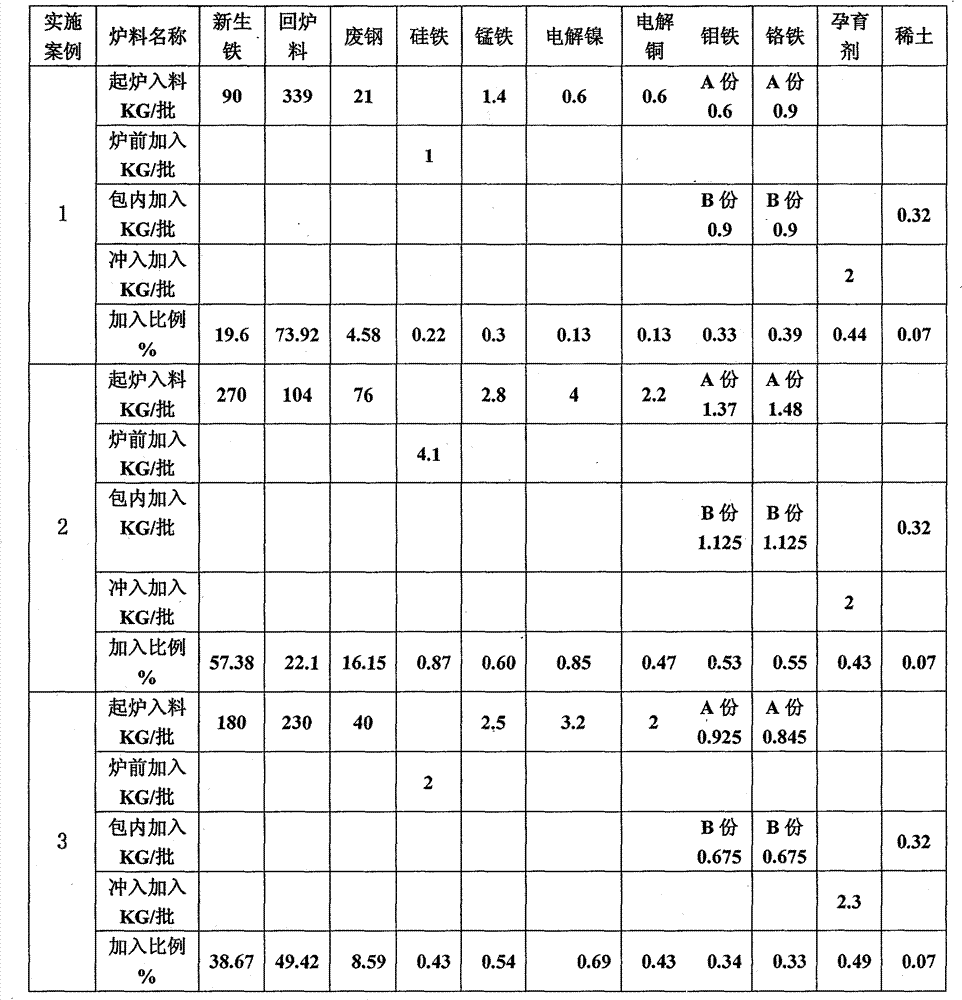

[0027] A) material selection, choose contained chemical composition weight percent by the Z10 foundry fresh iron shown in table 1;

[0028] B) batching, with step A) selected Z10 cast newborn iron, the casting riser of the alloy cast iron glass mold casting of this molten iron (Z10 molten iron of cast newborn iron) and scrapped castings are return charge, with contained chemical composition Ordinary carbon steel with a mass percentage of C 0.13%, Si 0.13%, Mn 0.36%, P0.041%, and S0.022% is used as scrap steel, with a silicon content defined in the Chinese national standard GB2272-87 as 72% ~80% of No. 75 ferrosilicon alloy is ferrosilicon, and all ingredients are prepared according to the percentage by weight shown in table 2, wherein: the amount of dividing ferromolybdenum and ferrochromium into two parts A and B is shown in table 2;

[0029] C) Ladle equipment, put part B ferromolybdenum (dried ferromolybdenum) and B part ferrochrome into the bottom of the first ladle, and t...

Embodiment 2

[0034] A) material selection, choose contained chemical composition weight percent by the Z10 foundry fresh iron shown in table 1;

[0035] B) batching, with step A) the selected Z10 cast newborn iron and the riser of the alloy cast iron glass mold casting with this molten iron (Z10 cast newborn iron) is the furnace charge, with the mass percentage of contained chemical element being C Ordinary carbon steel with 0.25%, Si0.32%, Mn 0.49%, P0.048% and S0.025% is used as steel scrap. No. 75 ferrosilicon alloys are ferrosilicon, and all ingredients are prepared by the percentage by weight shown in table 2, and all the other are the same as the description to step B) of embodiment 1;

[0036] C) ladle preparation, the ferromolybdenum of B part (dried ferromolybdenum) and the ferrochromium of B part are put into the bottom of the first ladle, then be 25% Re and 60% Re by mass percentage The rare earth mixture composed of Si and 15% iron is put into the first ladle and covered on th...

Embodiment 3

[0041] A) material selection, choose contained chemical composition weight percent by the Z10 foundry fresh iron shown in table 1;

[0042] B) batching, with step A) the selected Z10 cast newborn iron, the discarded casting of the alloy cast iron glass mold casting of this molten iron (Z10 cast newborn iron) is refurbishment charge, is C 0.54 with the mass percentage of contained chemical element %, Si0.50%, Mn 0.60%, P0.039% and S0.020% ordinary carbon steel as steel scrap, the 75% silicon content defined in the Chinese national standard GB2272-87 is 72% ~ 80% No. ferrosilicon alloy is ferrosilicon, and all raw materials are prepared by the percentage by weight shown in table 2, and all the other are with the description to the step B) of embodiment 1;

[0043] C) ladle preparation, put the ferromolybdenum of part B (dried ferromolybdenum) and the ferrochrome of part B into the bottom of the first ladle, and then add the three components of Re30%, Si55% and iron 15% by mass p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com