Preparation method of modified nanometer precipitated barium sulfate

A technology for precipitating barium sulfate and nano-precipitation, which is applied in chemical instruments and methods, fibrous fillers, dyed low-molecular organic compound treatment, etc., to achieve the effects of improving mechanical properties, simple process, and widening the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

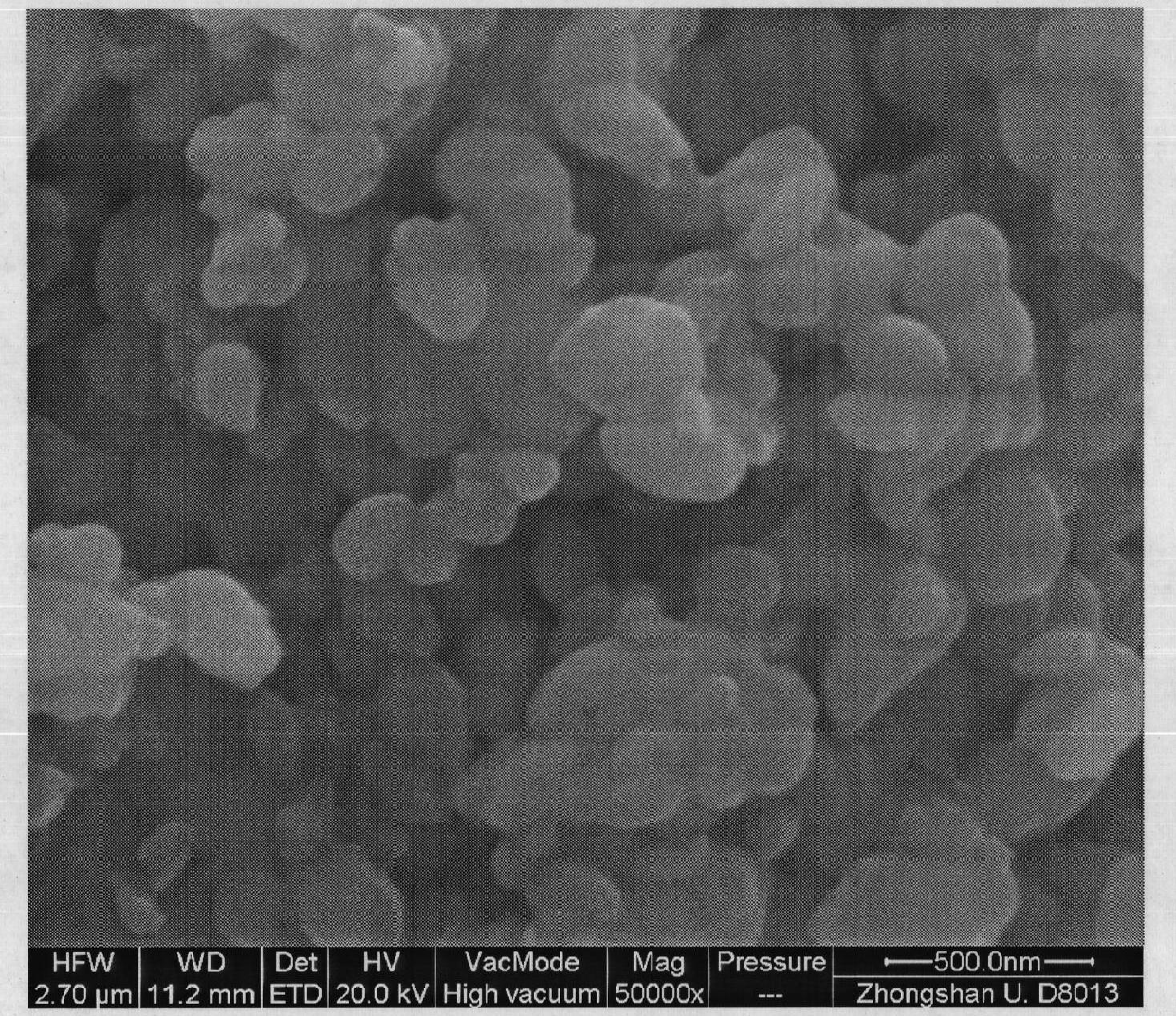

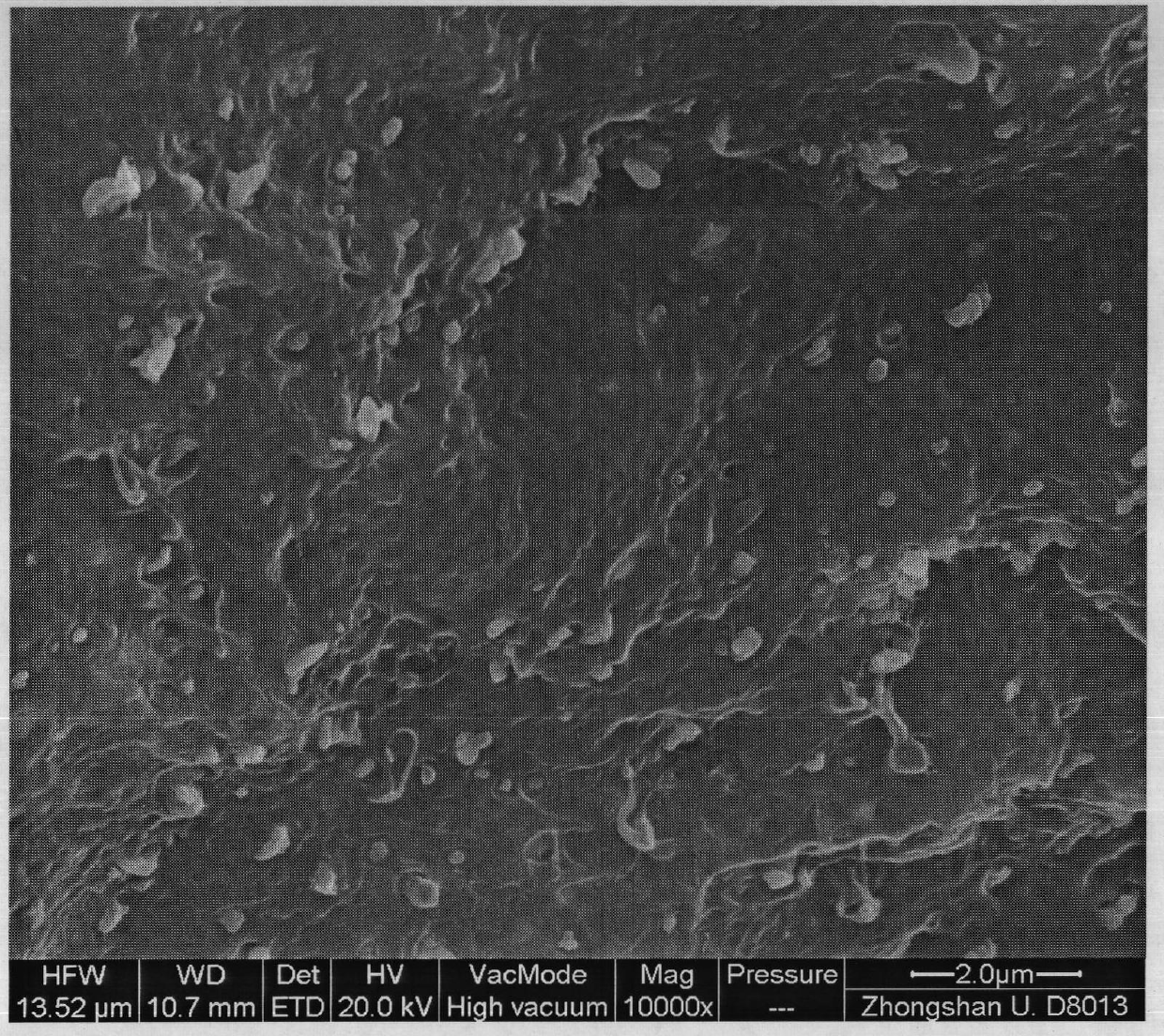

[0055] Add 600kg industrial grade light barium carbonate and 3400kg water in 5 cubic reactors, solid content is 15%. Add 25kg hydrochloric acid (concentration 31%) in the reactor. The stirring speed of the reactor was controlled at 200r / min, and then 300kg of concentrated sulfuric acid (concentration 98%) was added at a constant speed within 30-40 minutes until the reaction was completed. The pH at the end of the reaction was controlled at 5.5. After the barium sulfate slurry that reacted is filtered with 1000 order filter screens with strainer, obtain 720Kg precipitated barium sulfate. In precipitated barium sulfate, add the aqueous solution of sodium stearate weight content 10% at a uniform speed to precipitated barium sulfate and carry out surface treatment, adding time is 30 minutes, and sodium stearate weight is 20kg, and the temperature during modification is controlled at 80 ℃, then The modified nano-precipitated barium sulfate powder is obtained by dehydrating with a...

Embodiment 2

[0061] Add 1000kg of industrial-grade light barium carbonate to a 5 cubic reactor, add 3000kg of water, add 25kg of hydrochloric acid (concentration 31%), control the stirring speed of the reactor at 250r / min, and then add 500kg of concentrated barium carbonate at a constant speed within 30-40 minutes. Sulfuric acid (concentration 98%) until the reaction is complete. The pH at the end of the reaction was controlled at 5.6. After filtering the reacted barium sulfate slurry with a 1000 mesh filter screen with a filter screen, 1200Kg of precipitated barium sulfate is obtained. In precipitated barium sulfate, add the aqueous solution of sodium stearate weight content 5% at a constant speed to precipitated barium sulfate and carry out surface treatment, adding time is 20 minutes, and sodium stearate weight is 30kg, and the temperature during modification is controlled at 80 ℃, then The modified nano-precipitated barium sulfate powder is obtained by dehydrating with a filter press,...

Embodiment 3

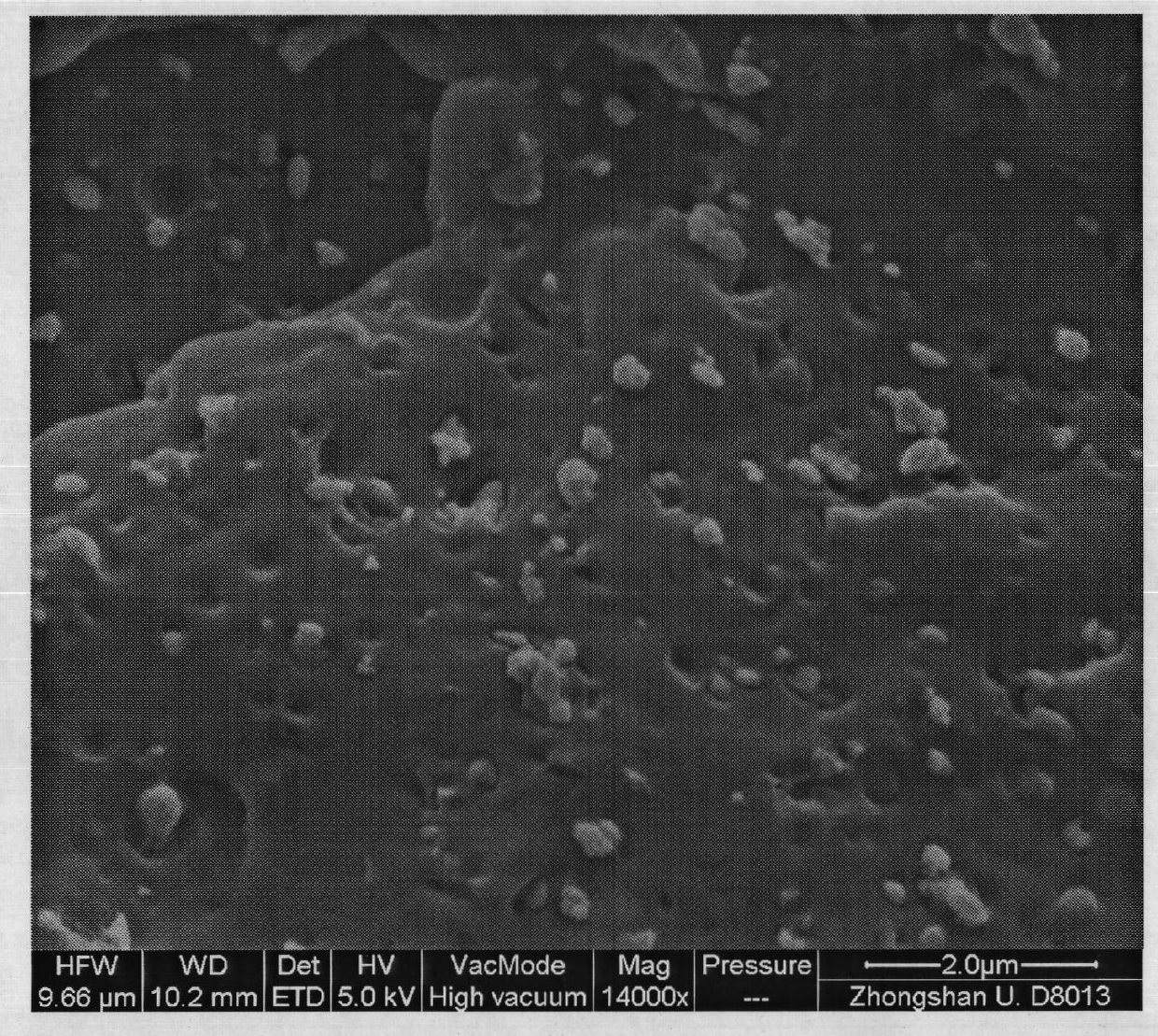

[0066] Add 200kg industrial-grade light barium carbonate and 3800kg water in a 5 cubic reaction kettle, and the solid content is 5%. Add 20kg of sodium chloride in the reactor. The stirring speed of the reactor was controlled at 100r / min, and then 100kg of concentrated sulfuric acid (concentration 98%) was added at a constant speed within 50 minutes until the reaction was completed. The pH at the end of the reaction was controlled at 6. After the barium sulfate slurry that reacted is filtered with 1000 order filter screens with strainer, obtain 240Kg precipitated barium sulfate. Add 10kg of vinyltrichlorosilane modifier to the precipitated barium sulfate at a uniform speed for surface treatment. The addition time is controlled at 40 minutes, and the temperature during modification is controlled at 55°C. Then dehydrate with a filter press and use a flash dryer Drying, automatic packaging machine packaging into modified nano-precipitated barium sulfate powder. The particle si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com