Polypeptin and preparation and application thereof

A technology of polypeptide bacteriocin and L-type, applied in the field of polypeptide bacterin and its preparation and application, can solve the problems of high residue, refractory degradation, high toxicity, etc., and achieve the effect of good safety and remarkable control effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: The new compound of formula (I) can be produced by fermenting P.elgii NBRC 100335 according to the following conditions.

[0034] 1. Inoculate the strain NBRC 100335 on the slant of nutrient agar medium for activation, and culture it at 30°C for 1-2 years;

[0035] 2. Put the slant seeds into 50mL seed culture medium in a 250mL Erlenmeyer flask, and culture at 30°C and 200rpm for 24 hours, which is the first-grade seed solution;

[0036] 3. Put the first-grade seed solution into 200mL seed medium in a 500mL Erlenmeyer flask, and shake and culture at 30°C and 200rpm for 24h to obtain the second-grade seed solution;

[0037] 4. Add 4L of fermentation medium to a fermenter with a total volume of 7L, add 0.1% polyether defoamer GPE, sterilize under high pressure steam at 115°C for 60min, cool to 30°C, and put 200ml of secondary seed liquid into the fermenter (5% inoculum size, v / v), the initial rotation is 450 rpm, the dissolved oxygen is kept above 30%, and the...

Embodiment 2

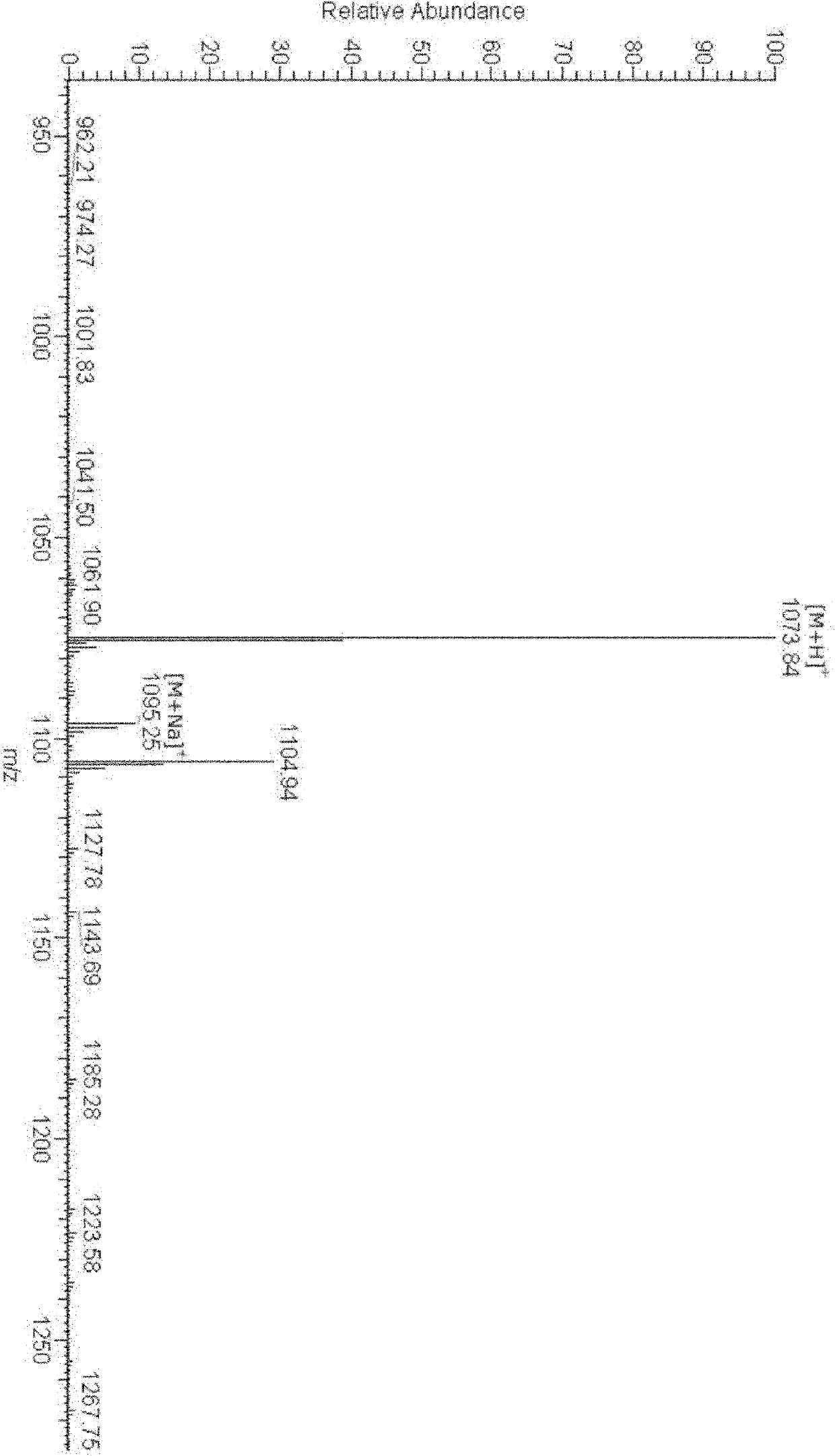

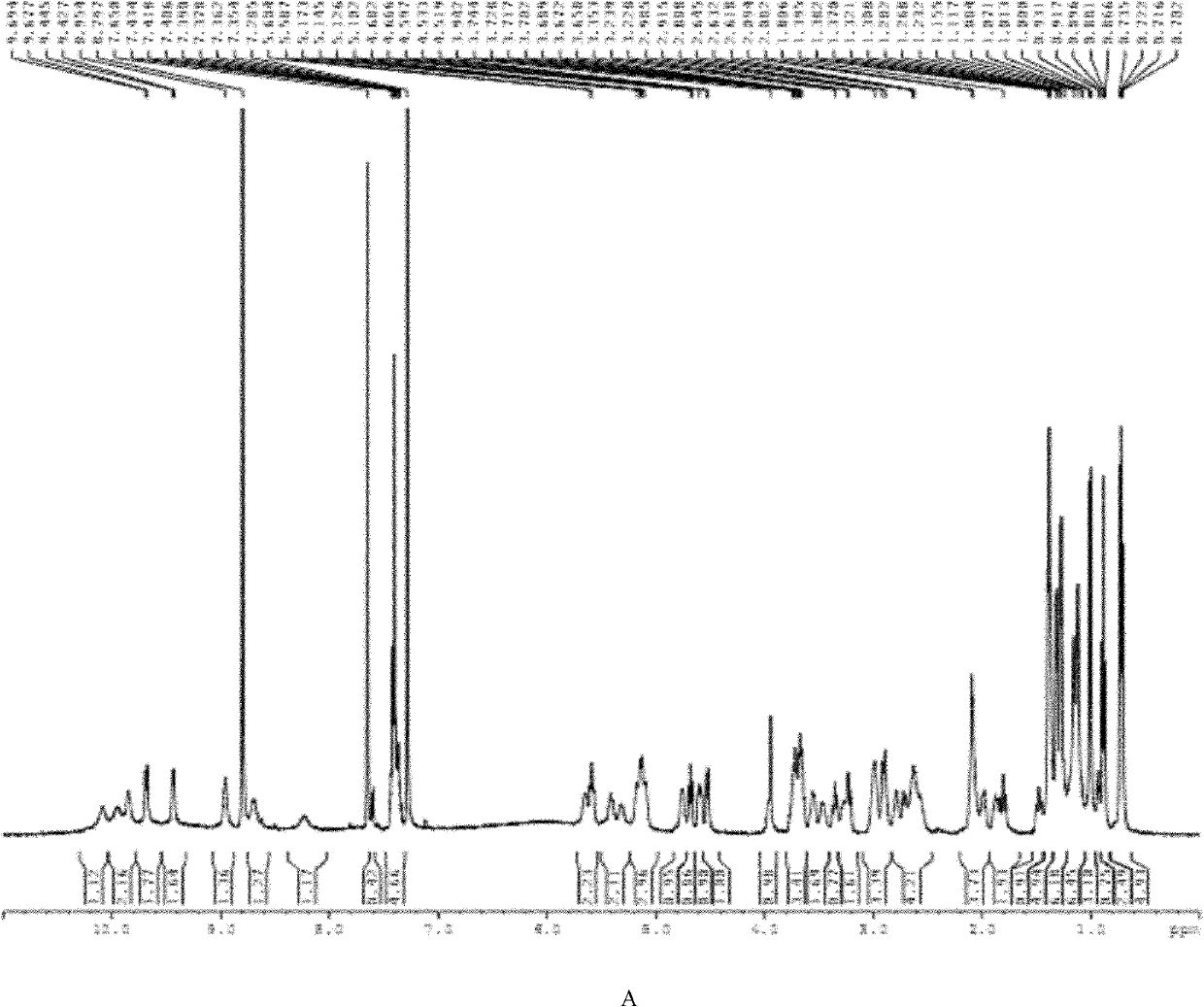

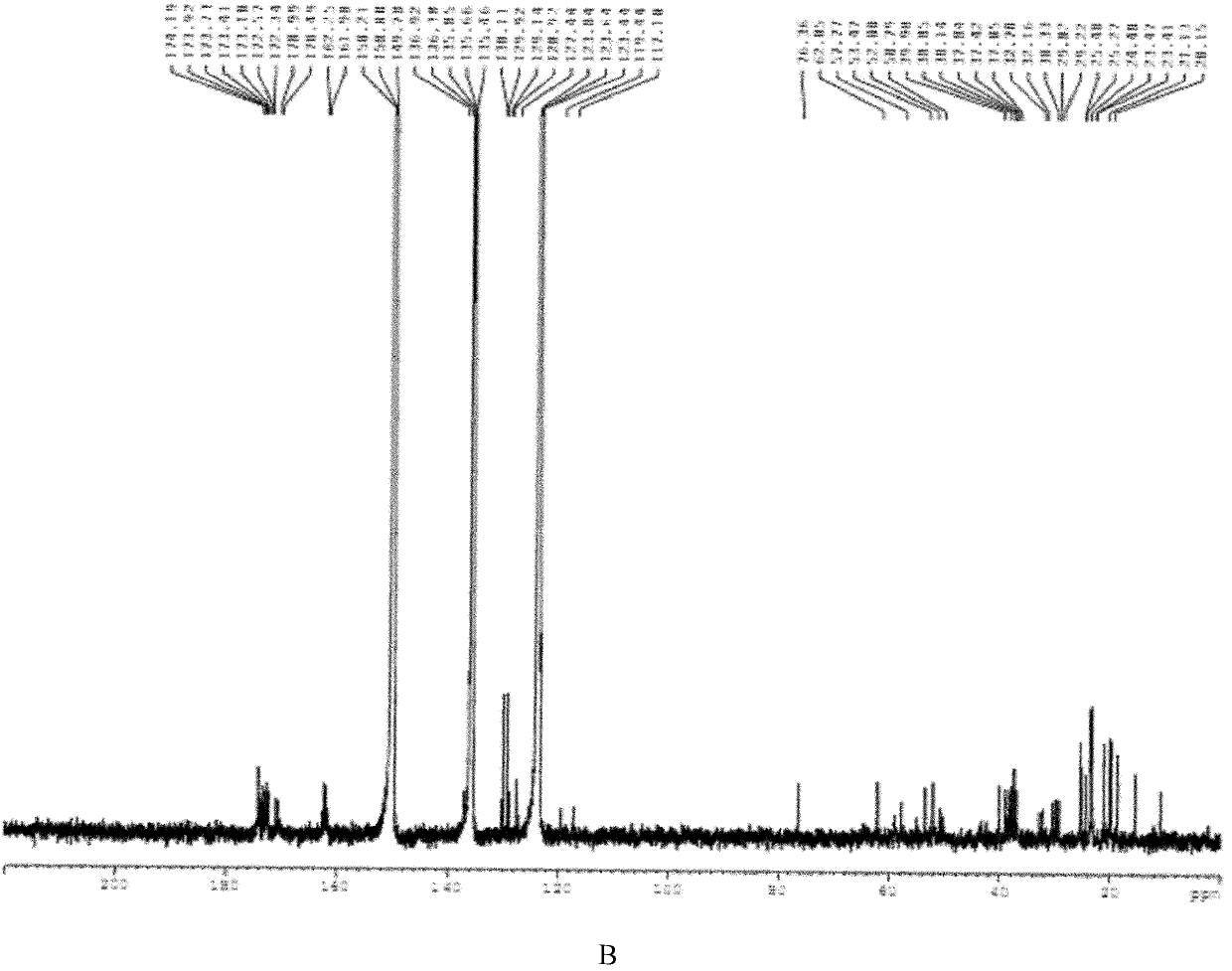

[0041] Embodiment 2: the separation and purification of formula (I) novel compound

[0042] The fermentation broth obtained in Example 1 can be separated and purified according to the following steps to obtain the pure product of the new compound of formula (I) provided by the present invention.

[0043] 1. Transfer the fermentation liquid to a centrifuge bottle, centrifuge at 6000rpm for 15 minutes, remove the bacteria, and obtain the fermentation supernatant;

[0044] 2. Add an equal volume of n-butanol to the supernatant, shake and extract, collect the extract, and repeat the raffinate with an equal volume of n-butanol.

[0045] 3. The two extracts were combined and concentrated to dryness in vacuo at 65° C. with a rotary evaporator to obtain a n-butanol extract concentrate.

[0046] 4. The n-butanol extract concentrate was resuspended in water, passed through an MCI GEL CHP20P (Mitsubishi Chemical) column, and then eluted with 20%, 70% and 100% methanol respectively, and ...

Embodiment 3

[0048] Embodiment 3: antibacterial activity assay

[0049] 1. Determination of the minimum inhibitory concentration of bacteria

[0050] 1) The new compound of formula (I) with a concentration of 200 μg / ml was prepared with Mueller Hinton broth medium, and doubled: 200, 100, 50, 25, 12.5, 6.25, 3.12, 1.56, 0.78, 0.39 μg / ml ml.

[0051] 2) Add 50 μl of the new compound solution of formula (I) at different concentrations (200-0.39 μg / m1) after serial dilution to the 1st to 10th wells of the 96-well polystyrene plate, and add 50 μl of Mueller Hinton to the 11th well Broth medium (0.2% beef extract powder, 1.75% acid hydrolyzed casein, 0.15% starch) was used as a growth control, and 100 μl of Mueller Hinton broth medium was added to the 12th well as a negative control. Positive controls were polymyxin B and vancomycin.

[0052] 3) After culturing the indicator bacteria for 24 hours, dilute to 10 with Mueller Hinton broth medium 6 cells / ml, add 50 μl of diluted bacterial soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com