Method for preparing calcium alginate microspheres with temperature response performance

A technology of calcium alginate and composite microspheres, applied in the field of materials, can solve the problems of lack of controlled release ability in response to physiological events, less research and application, and achieve good biocompatibility and biodegradability, wide application prospects, Simple and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

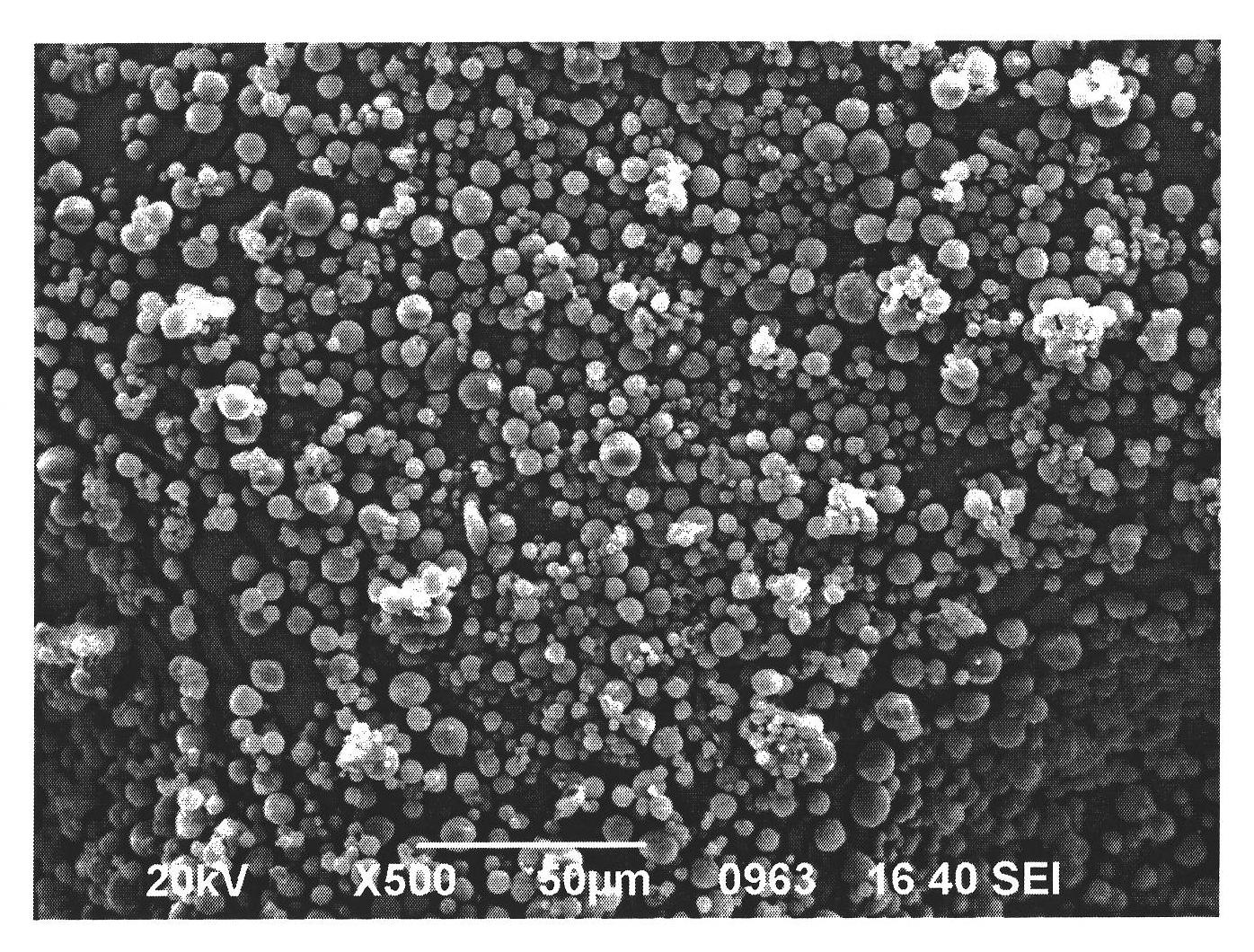

[0022] Add 0.4g sodium alginate, 0.8g N-ethylene caprolactam, 58.8g water in a 250mL three-necked flask, 0.02g azobisisobutyronitrile, that is, azobisisobutyronitrile is about 2.14% of the molar number of N-ethylenecaprolactam, Stir, fully mix and dissolve, remove oxygen such as filling with nitrogen for half an hour, then heat up to 60°C, and react for 5 hours. The reaction process can be accompanied by continuous stirring or intermittent stirring. The reaction mixture was cooled to room temperature, slowly added to 40 mL of n-hexane dissolved with 2 g of Span-85, stirred for 15 min, 2 g of Tween-85 (diluted with 2 mL of water) was added dropwise, and the emulsification was continued for 10 min. Finally, 25 mL of calcium chloride aqueous solution with a mass fraction of 8% was added dropwise, and stirred and solidified for 15 min. Precipitate with absolute ethanol, centrifuge, then wash with absolute ethanol and distilled water respectively, and freeze-dry to obtain the follo...

Embodiment 2

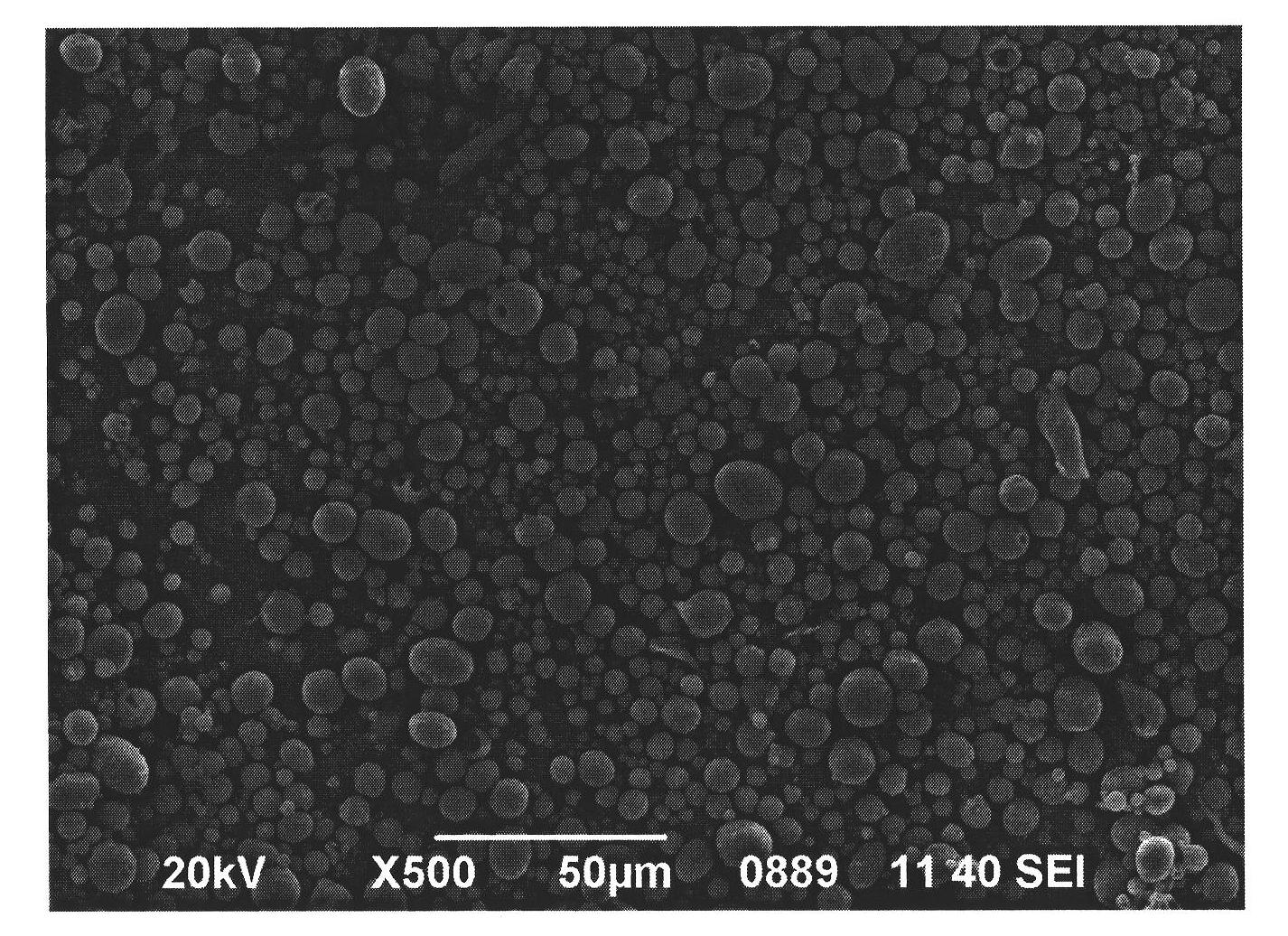

[0024] Roughly the same as the method of Example 1, the difference is that the consumption of sodium alginate, N-ethylene caprolactam, and azobisisobutyronitrile are respectively 0.6g, 0.6g, and 0.015g, and the above-mentioned azobisisobutyronitrile is about N - 2.12% by mole of ethylene caprolactam. The resulting finished product is as figure 2 shown.

Embodiment 3

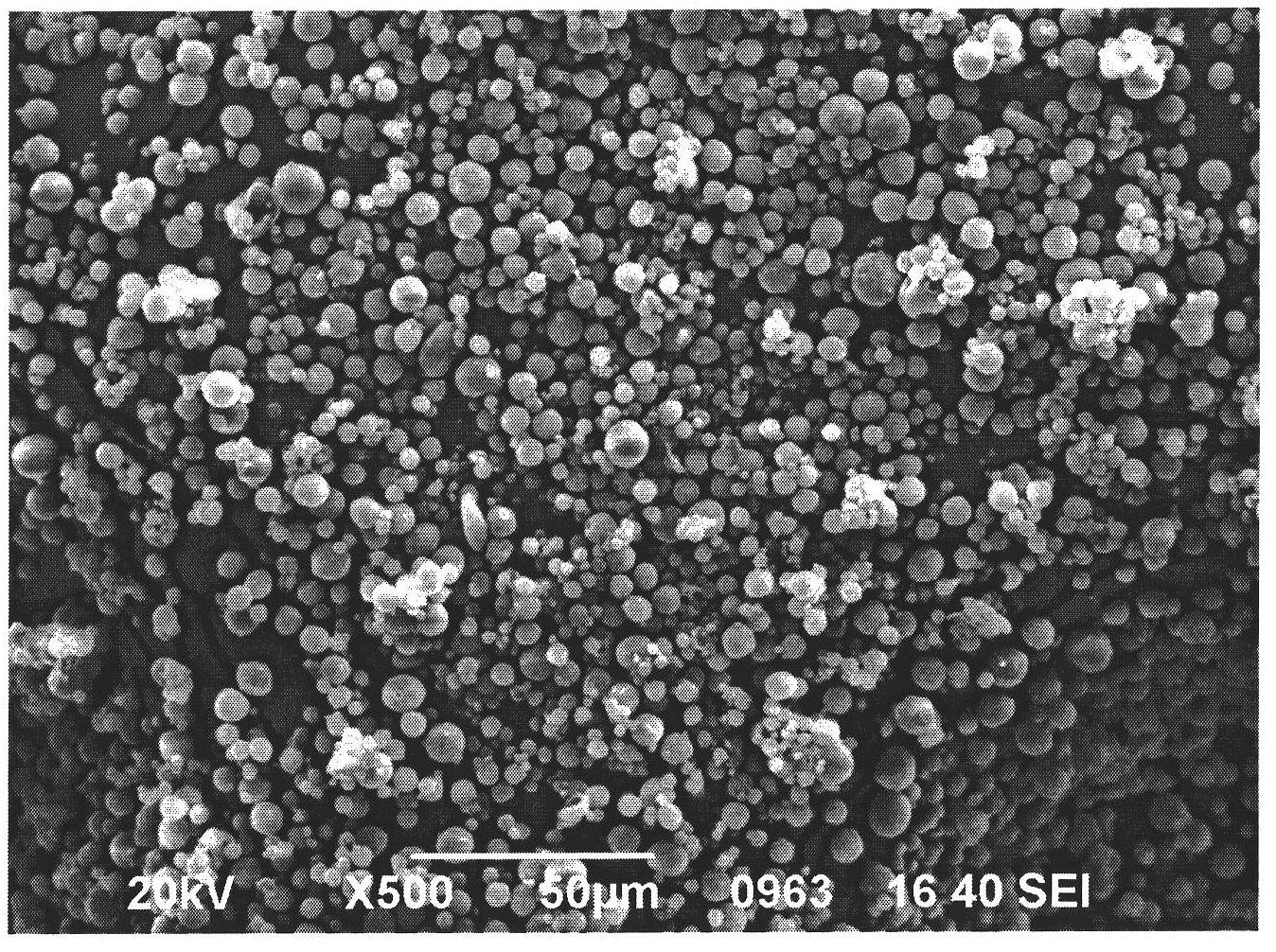

[0026] Roughly the same as the method of Example 1, the difference is that 0.8g sodium alginate, 0.4g N-ethylene caprolactam, 0.01g azobisisobutyronitrile are added, and the above-mentioned azobisisobutyronitrile is about 1% of the moles of N-ethylene caprolactam 2.13%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com