Method for producing biologic feed from cassava lees

A technology of cassava distiller's grains and biological feed, applied in animal feed, animal feed, applications, etc., can solve the problems of limiting the range of distiller's grain feed utilization, high content of distiller's grain crude fiber, and lack of popularization, so as to improve feed conversion efficiency and production High efficiency, weight gain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

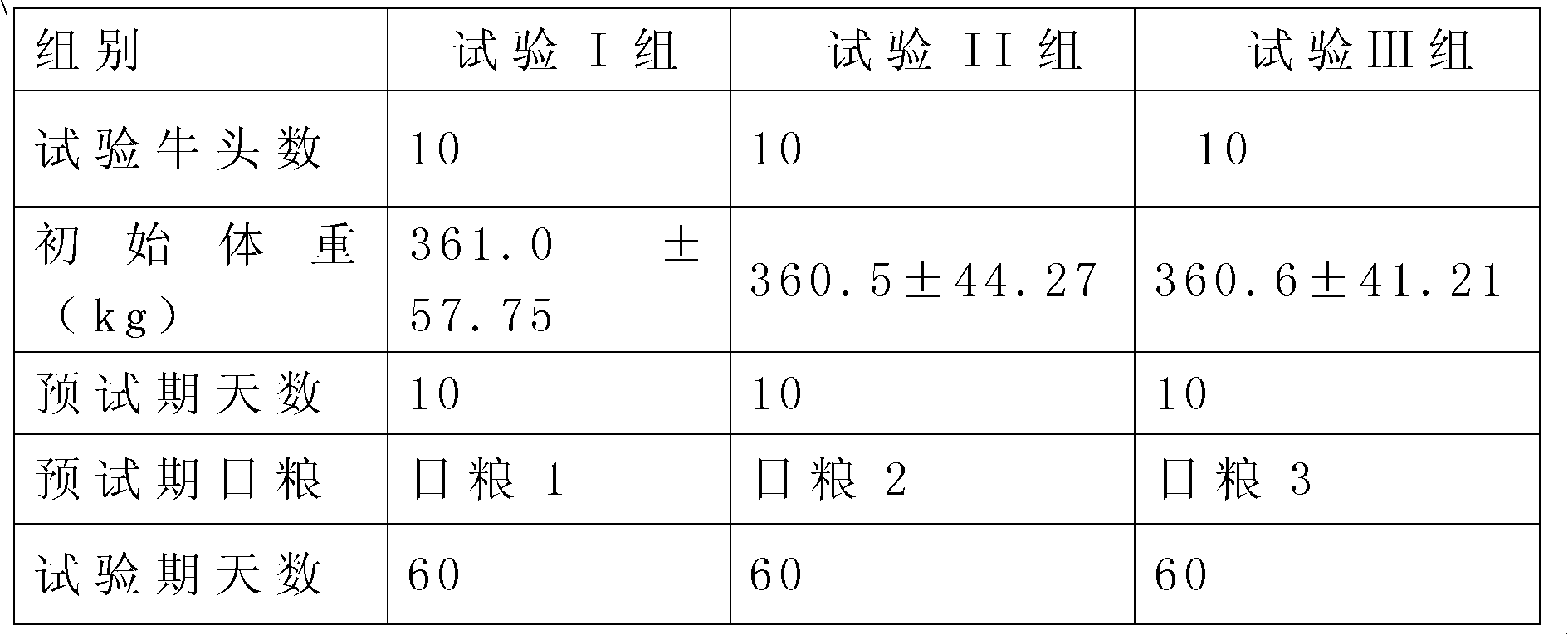

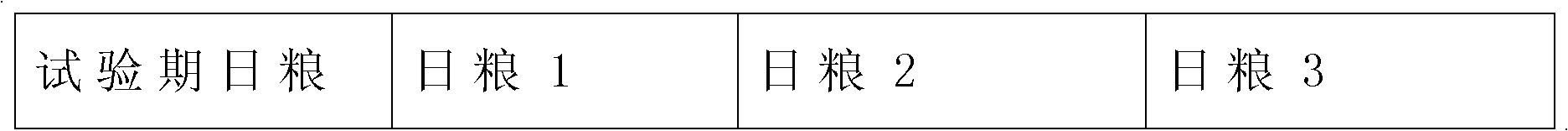

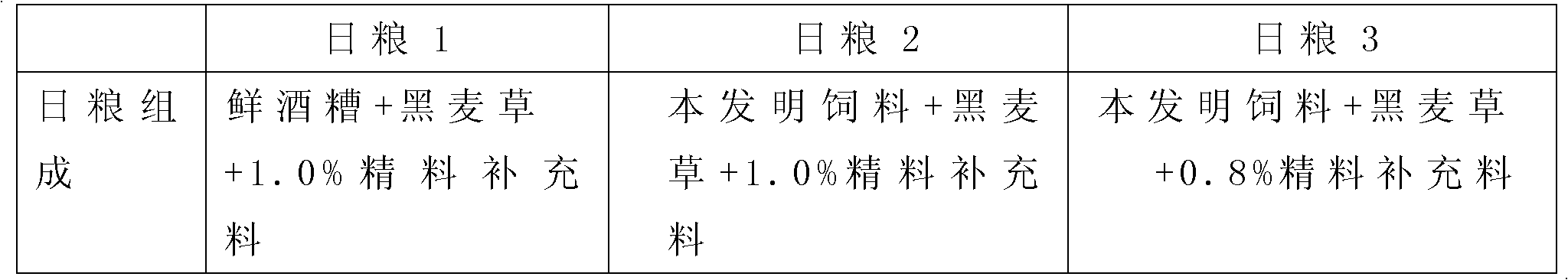

Examples

Embodiment 1

[0037] Mix fresh cassava distiller's grains, bran and soybean meal by weight 5:3:2, and add 1.5% (NH4 ) 2 SO 4 , and 0.2% KH 2 PO 4 Prepare the distiller's grain medium, mix the prepared Trichoderma korningii suspension, Trichoderma viride spore suspension, yeast seed liquid, and lactic acid bacteria seed liquid in a volume ratio of 1:1:1:1, and add to the above distiller's grains In the culture medium, add 20ml for every 100 grams of distiller's grains medium, put the above inoculated medium into the fermentation tank, first open it at 25-28°C for 48 hours, then compact it, cover it with a plastic film, and coat it with a layer of 10cm For thick yellow mud, it can be fermented anaerobically for 10 days and dried at 50-55°C. It was determined that the protein content of the product increased by 32.8%, the cellulose content decreased by 7.6%, and the number of lactic acid bacteria was 2.9×10 8 cells / mL, the number of yeasts was 2.7×10 7 individual / mL.

Embodiment 2

[0039] Mix fresh cassava distiller's grains, bran and soybean meal by weight 5:3:2, and add 1.0% (NH 4 ) 2 SO 4 , and 0.4% KH 2 PO 4 Prepare distiller's grain medium, mix the prepared Trichoderma corning suspension, Trichoderma viride suspension, yeast seed liquid, and lactic acid bacteria seed liquid in a volume ratio of 1:1.2:0.5:0.5 and add them to the above medium , add 30ml per 100g of distiller's grains medium, put the above inoculated medium into the fermentation tank, first open it at 25-28°C for 72h, then compact it, cover it with a plastic film, and coat a layer of 8cm thick yellow Mud, anaerobic fermentation for 15 days, then dried at 50-55°C. It was determined that the protein content of the product increased by 33.4%, the cellulose content decreased by 6.7%, and the number of lactic acid bacteria was 3.7×10 8 cells / mL, the number of yeasts was 3.4×10 7 individual / mL.

Embodiment 3

[0041] Mix fresh cassava distiller's grains, bran and soybean meal in a weight ratio of 5:3:2, and add 1.2% of the total weight of fresh cassava distiller's grains, bran and soybean meal (NH 4 ) 2 SO 4 , and 0.3% KH 2 PO 4 Prepare distiller's grain medium, mix the prepared Trichoderma corning suspension, Trichoderma viride suspension, yeast seed liquid, and lactic acid bacteria seed liquid in a volume ratio of 1:2:0.8:0.8 and add them to the above medium , add 20ml per 100g of distiller’s grains medium, put the above-mentioned inoculated medium into the fermentation tank, first open it at 25-28°C for 26 hours, then compact it, cover it with a plastic film, and coat a layer of 5cm thick yellow Mud, anaerobic fermentation for 20 days, then dried at 50-55°C. It was determined that the protein content of the product increased by 31.9%, the cellulose content decreased by 8.2%, and the number of lactic acid bacteria was 2.3×10 8 cells / mL, the number of yeasts is 2.5×10 7 indiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com