Feed compound sweetener and production method thereof

A compound sweetener and feed technology, applied in the direction of animal feed, animal feed, additional food elements, etc., can solve the problems of easy grading, reduce the number of sweetener particles, difficult to disperse, etc., and is suitable for large-scale promotion. Application, reduction of moisture absorption and caking, uniform and consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1. Proportion

[0045]

components

parts by weight

Saccharin and its salts

60

synergist

3

Acesulfame K

7

1

adenosine monophosphate

1

1

silica

3

[0046] 2. Process and parameters

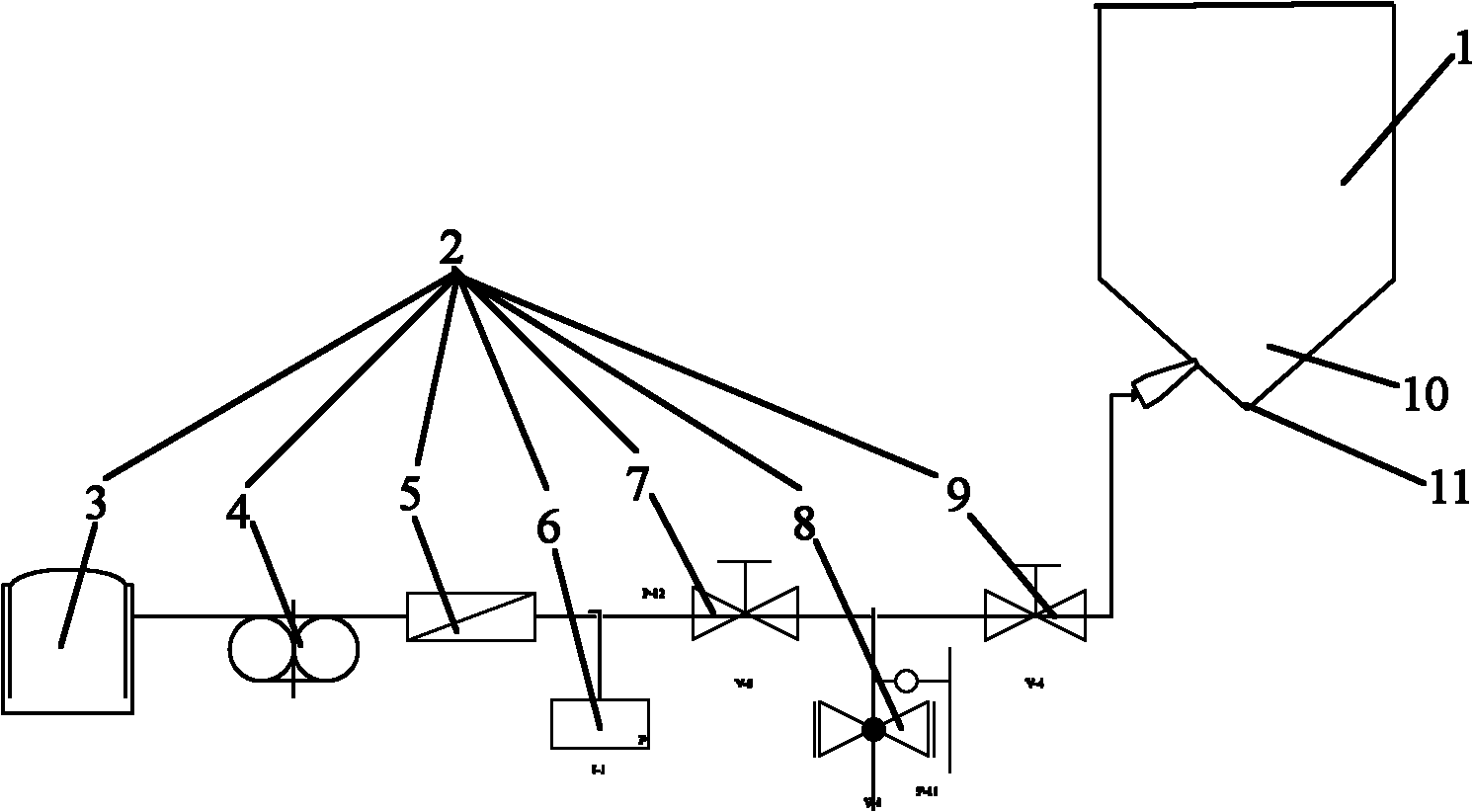

[0047] 1. Molecular fusion process

[0048] According to the above ratio, add 500 parts by weight of clean water into the fusion kettle, heat to 60-85°C, add sodium saccharin, stir and mix evenly to completely dissolve all materials, the solution is transparent, and the temperature is kept at 60-85°C. Then add the synergist and enhancer into the fusion kettle, stir and mix evenly to dissolve all the materials completely, the solution is transparent, and the temperature is kept at 60-85°C. After the fused material is purified through a tubular filter, it is transferred to a transfer...

Embodiment 2

[0074] 1. Proportion

[0075]

components

parts by weight

Saccharin and its salts

40

synergist

5

Acesulfame K

5

5

enhancer

2

Guanylate

2

1

silica

0.1

[0076] Production technology is with embodiment 1.

[0077] The product prepared in Example 2 was analyzed, the analysis method was referring to Example 1, and the results similar to the product of Example 1 were obtained.

Embodiment 3

[0079] 1. Proportion

[0080]

components

parts by weight

Saccharin and its salts

sodium saccharin

90

synergist

1

Acesulfame K

2

2

enhancer

0.2

[0081]

Guanylate

0.2

0.1

silica

5

[0082] Production technology is with embodiment 1.

[0083] The product prepared in Example 3 was analyzed, and the analysis method was referred to Example 1, and a result similar to that of the product of Example 1 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com