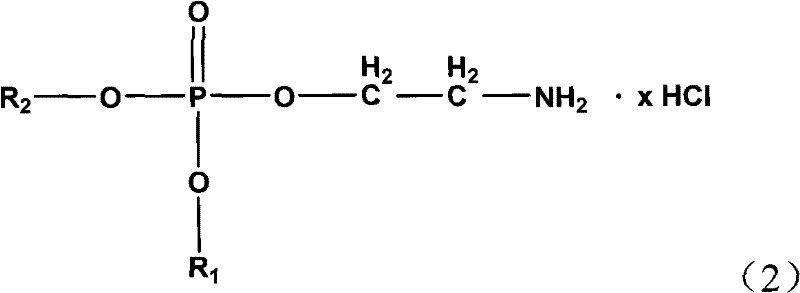

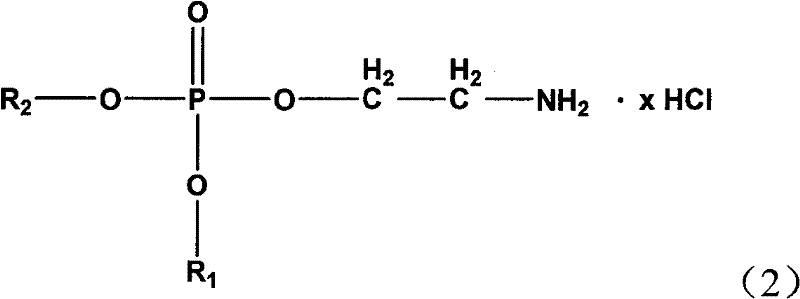

Method for preparing phosphorylethanolamine compound

A technology of phosphoethanolamine and compounds, which is applied in the field of biochemistry, can solve the problems of lower yield, lower product quality, and more wastes, and achieve the effects of simple, safe and reasonable process, short production cycle, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 50kg of water into the 100L reactor, heat up to 80°C, add 14.2kg of 100% phosphorus pentoxide, then add 12.2kg of 100% ethanolamine, remove water for 2 hours at a vacuum degree of -0.098kPa, and then heat up to 100°C, 120°C, 140°C, 160°C, 180°C, 200°C respectively at a vacuum degree of -0.098kPa or above to remove water for 2 hours, then crush the agglomerates and then dry at 160°C at a vacuum degree of -0.098kPa or above After 2 hours, 27.1 kg of white solid powder of monoethanolamine phosphate was obtained, with a melting point of 236.6-237.6° C., a yield of 96%, and a purity of ≥99.3%.

Embodiment 2

[0032] Add 85% phosphoric acid (H 3 PO 4 ) aqueous solution 500kg, add 265kg (61.05) of 100% ethanolamine at room temperature, raise the temperature to 80°C, remove water for 2 hours at a vacuum degree above -0.098kPa, then raise the temperature to 100°C, 120°C, 140°C, 160°C, 180°C ℃, 200 ℃, vacuum dewatering at a vacuum degree of -0.098kPa or above for 2 hours, the agglomerates were crushed, and then dried at 160 ℃ at a vacuum degree of -0.098kPa or above for 2 hours to obtain 593kg of white solid powder of monoethanolamine phosphate, melting point 239.8 ~242°C, yield 97%, purity 99.5%.

Embodiment 3

[0034] Add 61.4kg of 50% phosphorus oxychloride toluene solution into a 100L reactor, then add 12.2kg of 100% ethanolamine, keep at 80°C for 2 hours at a vacuum degree of -0.098kPa, and then raise the temperature to 100°C, 120°C , 140°C, 160°C, and 180°C were kept at a vacuum degree of -0.098kPa or more for 2 hours respectively, and the tail gas was condensed to obtain an aqueous solution of hydrogen chloride. Monoethanolamine hydrochloride white solid powder 32.3kg, melting point 247.5-248.9°C, yield 91%, purity ≥ 99.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com