Method for preparing high-purity annatto

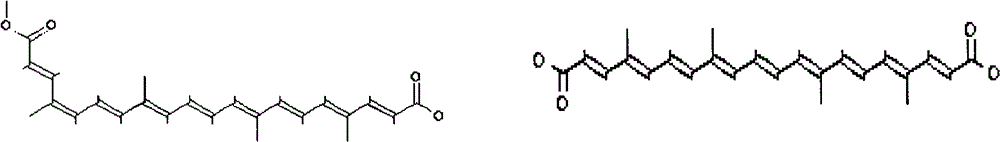

An annatto, high-purity technology, applied in the field of phytochemistry, can solve the problems of low annatto yield, crude pigment products, limited application scope, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

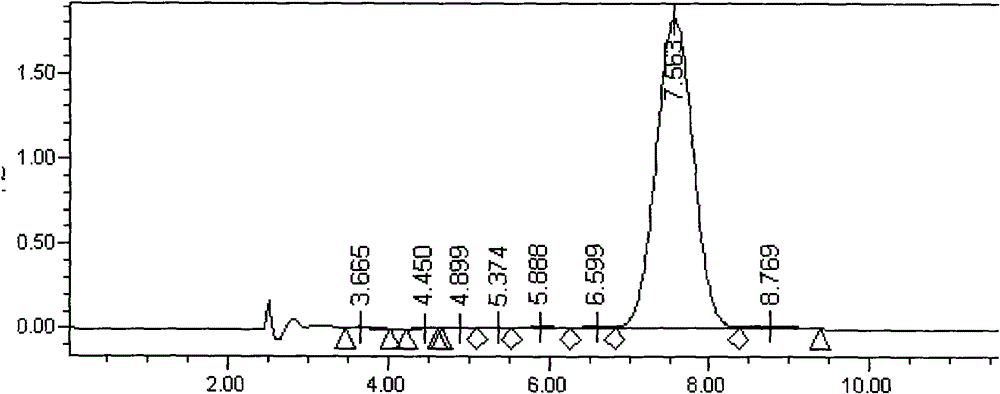

Image

Examples

Embodiment 1

[0020] Embodiment 1: the annatto seed is added in the aqueous solution of ethanol or acetone of 2~10 times of (v / w) amount, promptly annatto seed takes weight gram or kilogram as unit of measurement, and the aqueous solution of ethanol or acetone takes volume liter or milliliter For the unit of measurement, the present embodiment gets 1000 grams of annatto seeds (annatto content is 2.5%), adds 4000 ml of ethanol with a volume concentration of 60%, and filters after stirring for 1 hour at 40° C., and the gained annatto extract filtrate is diluted with water to When the ethanol concentration is 50%, pass through the D312, XAD-16 or X-5 macroporous resin adsorption column with a height-to-diameter ratio of 3:1 and a loading capacity of 400ml at a flow rate of 1BV / h, and the adsorption flow rate is controlled at 1.5-2BV / h h, after adsorption, use a volume concentration of 70% ethanol aqueous solution to carry out saturated resin column purification, remove most of the sugar and oth...

Embodiment 2

[0021] Embodiment 2: The difference between this embodiment and Example 1 is to get 10 kilograms of annatto seeds (annatto content is 2.5%), add ethanol 50L of volume concentration 65%, filter after stirring at 45 ℃ for 1.5 hours. Gained annatto extract filtrate adds water and is diluted to ethanol concentration when being 50%, with the flow velocity of 1.5BV / h, be 4: 1 by height-to-diameter ratio, and loading capacity is the CAD-40 or LX700 macroporous resin resin adsorption column of 7500ml to carry out For the capture and enrichment of annatto, the adsorption flow rate is controlled at 1.5-2BV / h. After adsorption, use 70% ethanol aqueous solution to perform saturated resin column purification. After removing most of the sugar and other polar impurities, 95% ethanol aqueous solution (or methanol or acetone) adopt the discontinuous gradient desorption method to carry out resin desorption, the desorption flow rate is controlled at 0.5BV / h, when HPLC detects that annatto flows o...

Embodiment 3

[0022] Embodiment 3: The difference between the present embodiment and Example 1 is to get 100 kilograms of annatto seeds (annatto content is 2.5%), add ethanol 600L of volume concentration 70%, filter after stirring 2 hours under 50 ℃. Gained annatto extract filtrate adds water and is diluted to ethanol concentration when being 50%, with the flow velocity of 2BV / h, be that the adsorption column that HZ818 or HZ801 or D1300 macroporous resin loading capacity is 120L with the flow velocity of 2BV / h passes through aspect ratio is 120L to carry out annatto extraction. For orange capture and enrichment, the adsorption flow rate is controlled at 1.5-2BV / h. After adsorption, use 70% ethanol aqueous solution to perform saturated resin column purification, remove most of the sugar and other polar impurities, and then use 95% ethanol aqueous solution (or methanol or acetone) adopt the discontinuous gradient desorption method to carry out resin desorption, the desorption flow rate is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com