Method for preparing nano-level active calcium carbonate for rubber and plastic

An activated calcium carbonate, nano-scale technology, applied in the direction of calcium carbonate/strontium/barium, dyed low-molecular-weight organic compound treatment, dyed high-molecular-weight organic compound treatment, etc. The effect of energy saving, low energy consumption and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

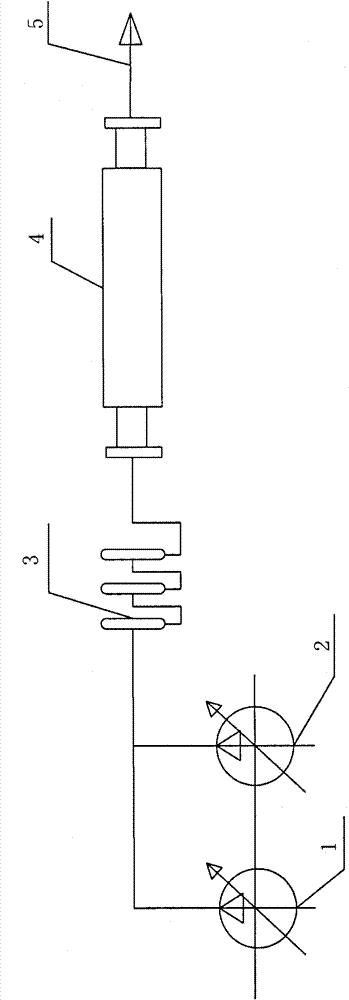

[0040] Such as figure 1 It is a transmission electron microscope photo, a method for preparing nanoscale active calcium carbonate for rubber and plastics, the method comprising the steps of:

[0041] a. Put calcium oxide and water into the paddle digester at a ratio of 1:3.5~5, the calcium hydroxide suspension passes through a 100~200 mesh sieve and enters the coarse stock tank, and the slurry remains in the coarse stock tank for 24 to 100 hours, After the static coarse pulp undergoes secondary hydrocyclone separation, it enters the pulping tank, and the pulp is blended in the pulping tank to a calcium hydroxide mass percentage concentration of 15-22;

[0042] b. The measured calcium hydroxide slurry enters the metering tank for metering;

[0043] c. According to the concentration of the calcium hydroxide slurry, inject the crystallization directing agent into the carbonization tower, stir for 5 to 50 minutes and then enter the carbonization tower;

[0044] d. In the initial...

Embodiment 1

[0052] A method for preparing nanoscale active calcium carbonate for rubber and plastics, the method comprising the steps of:

[0053] a. Calcium oxide and water enter the paddle digester in a ratio of 1:3.5, and the water can be tap water or treated nano-calcium carbonate production wastewater; the calcium hydroxide suspension enters the coarse stock tank through a 120-mesh sieve, The slurry was left standing in the coarse pulp pool for 24 hours, and the static coarse pulp was subjected to secondary hydrocyclone separation and then entered into the slurry mixing tank, where the slurry was adjusted to a calcium hydroxide mass percentage concentration of 15;

[0054] b. The measured calcium hydroxide slurry enters the metering tank for metering;

[0055] c. According to the concentration of the calcium hydroxide slurry, inject a crystallization directing agent into the carbonization tower. The amount of the crystallization directing agent is adjusted according to the quality in...

Embodiment 2

[0061] A method for preparing nanoscale active calcium carbonate for rubber and plastics, the method comprising the steps of:

[0062]a. Calcium oxide and water enter the paddle digester in a ratio of 1:4.5. The water can be tap water or treated nano-calcium carbonate production wastewater. The calcium hydroxide suspension enters the coarse stock tank through a 150-mesh sieve. The slurry was left standing in the coarse pulp pool for 30 hours, and the static crude pulp was subjected to secondary hydrocyclone separation and then entered into the slurry mixing tank, where the slurry was adjusted to a calcium hydroxide mass percentage concentration of 22;

[0063] b. The measured calcium hydroxide slurry enters the metering tank for metering;

[0064] c. According to the concentration of calcium hydroxide slurry, inject the crystallization directing agent into the carbonization tower. The amount is adjusted according to the quality index of the final product and the user's require...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com