Activating agent for enhancing degradability of oil degrading bacteria as well as application and use method thereof

A technology of activator and degrading bacteria, which is applied in chemical instruments and methods, preservation of microorganisms, water/sludge/sewage treatment, etc., can solve problems affecting system treatment efficiency, BOD increase, scum accumulation, etc., to achieve efficient metabolism, Reduce processing costs and improve processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: the preparation method of the activator that strengthens grease degradation ability

[0015] The activator for enhancing the degradation ability of the oil-degrading bacteria includes a microbial activator, a vitamin solution and a trace element solution with a volume ratio of 1:1:1. The preparation methods of the three solutions are as follows: Take Tween801.0mL, KH 2 PO 4 0.02g, MgSO 4 ·7H 2 00.01g, K 2 HPO 4 Put 0.15g, 0.5g of sucrose, and 1000mL of distilled water in a 1L narrow-mouth bottle, stir with a glass rod to dissolve it, and obtain a microbial stimulator; take 0.5g of vitamin A, 10.5g of vitamin B, 0.5g of vitamin C and 1000mL of distilled water In the bottle, stir with a glass rod to dissolve it to obtain a vitamin solution; take ZnSO 4 ·7H 2 O 0.22g, CoCl 2 ·6H 2 O 0.08g, MnCl 2 4H 2 O 0.54g, CuSO 4 ·5H 2 O 0.08g, NaMoO 4 ·H 2 O 0.08g, NiCl 2 ·6H 2 O 0.08g, Na 2 SeO 3 0.08g, HBO 4 0.005g and 1000mL of distilled water were...

Embodiment 2

[0016] Embodiment 2: the preparation method of the activator that strengthens grease degradation ability

[0017] The activator for enhancing the degradation ability of the oil-degrading bacteria includes a microbial activator, a vitamin solution and a trace element solution with a volume ratio of 1:1:1. The preparation methods of the three solutions are as follows: Take Tween8010.0mL, KH 2 PO 4 1.0g, MgSO 4 ·7H 2 00.5g, K 2 HPO 4 Put 4.5g, 20g of sucrose, and 1000mL of distilled water in a 1L narrow-mouth bottle, and stir it with a glass rod to dissolve it to obtain a microbial stimulator; Stir with a rod to dissolve it, and obtain a vitamin solution; take ZnSO 4 ·7H 2 O 0.66g, CoCl 2 ·6H 2 O 0.40g, MnCl 2 4H 2 O1.44g, CuSO 4 ·5H 2 O 0.80g, NaMoO 4 ·H 2 O 0.73g, NiCl 2 ·6H 2 O 0.61g, Na 2 SeO 3 0.66g, HBO 4 0.02g and 1000mL of distilled water were placed in a 1L narrow-mouth bottle, stirred with a glass rod to dissolve, and a trace element solution was obt...

Embodiment 3

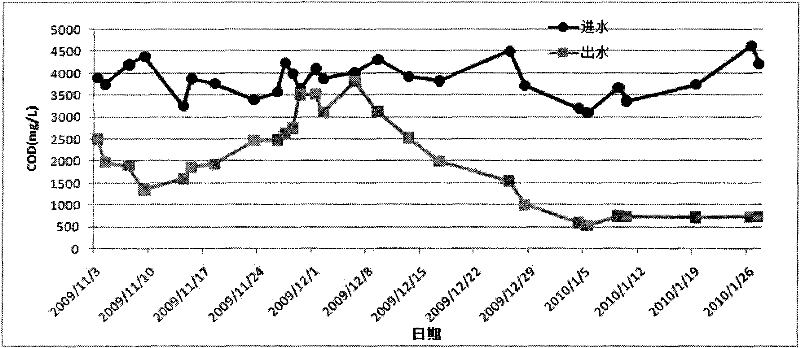

[0018] Embodiment 3: The activator is added to the upflow anaerobic sludge bed reactor (UASB reactor)

[0019] An upflow anaerobic sludge bed reactor for treating oily sewage in the laboratory, with an effective volume of 18L. According to the dosage of 0.03% of the volume of sewage, take 5.4mL of microbial activator and add it to the reactor. Dosing once every 8 days thereafter, the dosage is the same as above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com