Selenium urea formaldehyde roller pelleting compound fertilizer and production method thereof

A technology of drum granulation and urea formaldehyde, applied in potash fertilizers, phosphate fertilizers, fertilizer forms, etc., can solve the problems of inability to produce compound fertilizers, large ratio limitations, ecological environment pollution, etc., and achieve crop yield, less water, and savings. energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

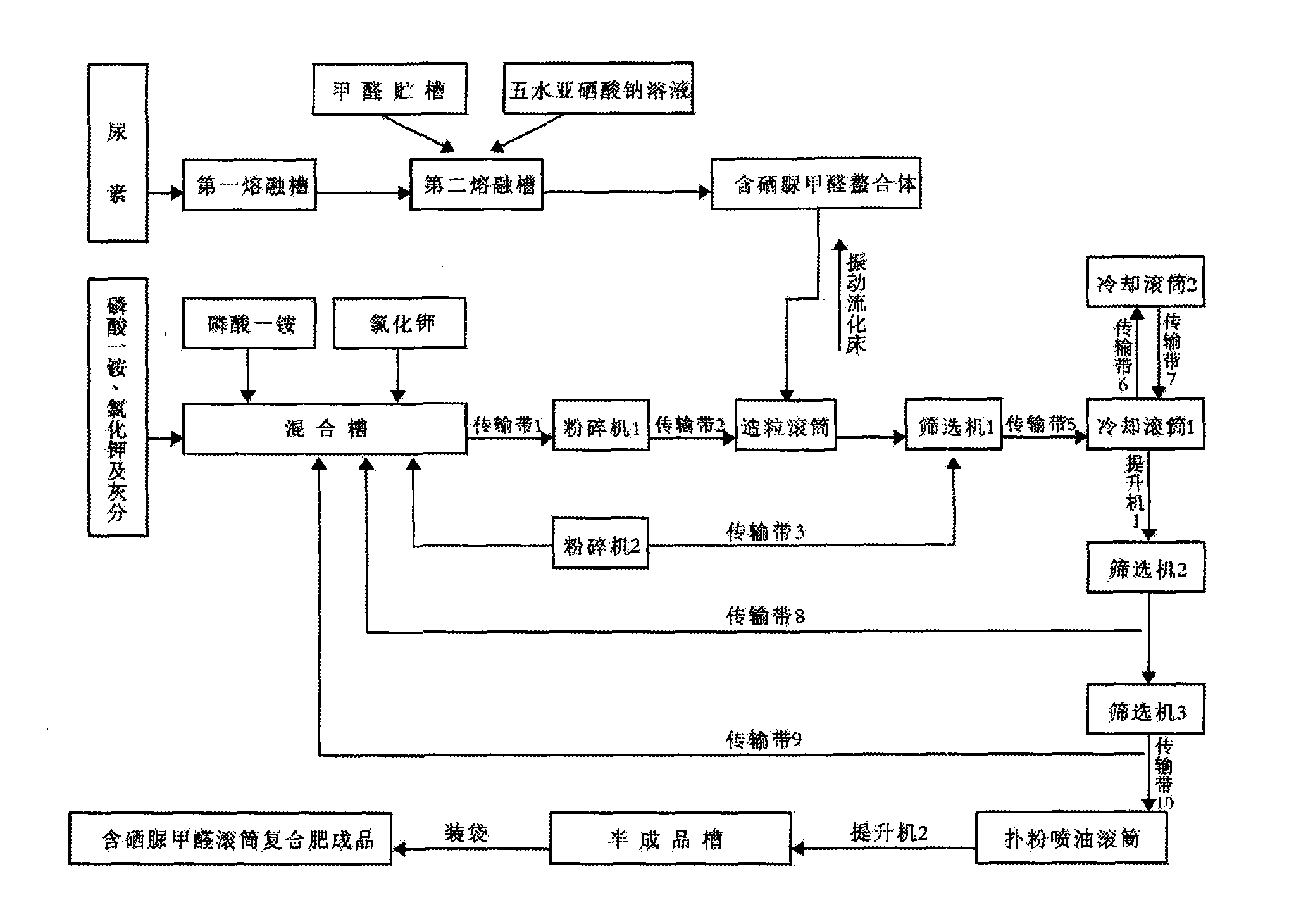

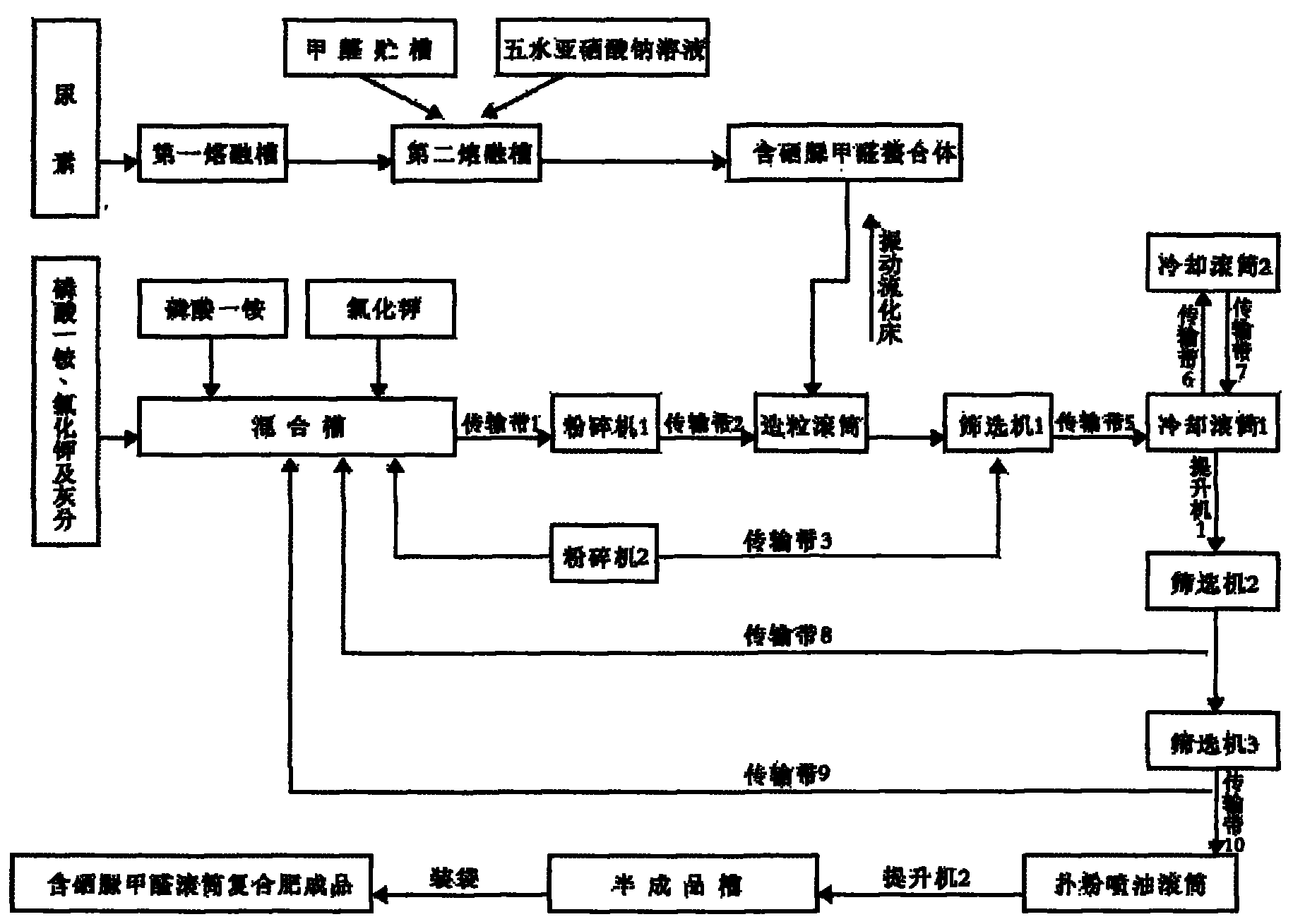

Method used

Image

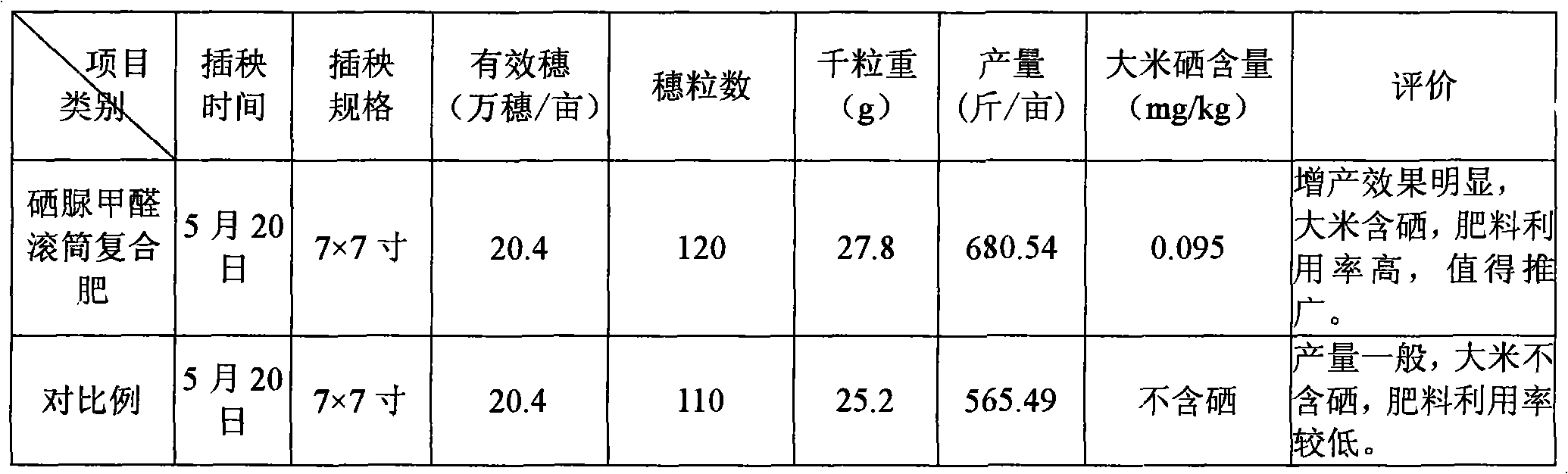

Examples

Embodiment 1

[0020] A selenourea-formaldehyde drum granulation compound fertilizer, comprising urea-formaldehyde, potassium chloride, monoammonium phosphate, sodium selenite pentahydrate, moisture and ash, each composition is by weight: urea-formaldehyde 0.44, potassium chloride 0.25, phosphoric acid Monoammonium 0.17, sodium selenite pentahydrate 0.0187, moisture 0.03, ash 0.02. Among them, urea-formaldehyde is synthesized by urea and formaldehyde in a weight ratio of 2:3, and urea is selected from N-P 2 o 5 -K 2 O=46-0-0.

Embodiment 2

[0022] A selenourea-formaldehyde roller granulation compound fertilizer, comprising urea-formaldehyde, potassium chloride, monoammonium phosphate, sodium selenite pentahydrate, moisture and ash, each composition is by weight: urea-formaldehyde 0.38, potassium chloride 0.25, phosphoric acid Monoammonium 0.21, sodium selenite pentahydrate 0.0281, moisture 0.035, ash 0.0969. Among them, urea-formaldehyde is synthesized by urea and formaldehyde in a weight ratio of 2:3, and urea is selected from N-P 2 O5-K 2 O=46-0-0.

Embodiment 3

[0024] A selenourea-formaldehyde drum granulation compound fertilizer, comprising urea-formaldehyde, potassium chloride, monoammonium phosphate, sodium selenite pentahydrate, moisture and ash, each composition is by weight: urea-formaldehyde 0.74, potassium chloride 0.08, phosphoric acid Monoammonium 0.11, sodium selenite pentahydrate 0.0187, moisture 0.03, ash 0.02. Among them, urea-formaldehyde is synthesized by urea and formaldehyde in a weight ratio of 2:3, and urea is selected from N-P 2 o 5 -K 2 O=46-0-0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com