Method for preparing hydrogen chloride and ammonia by utilizing ammonium chloride

A technology of ammonium chloride and hydrogen chloride, applied in the direction of chlorine/hydrogen chloride, preparation with chloride, preparation/separation of ammonia, etc., can solve the problem of low reaction rate of acid release, lack of proper control of the particle size of raw material ammonium chloride, and insufficient purity Advanced problems, to achieve the effect of improving reaction rate and reaction efficiency, avoiding ammonia synthesis process, and avoiding side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

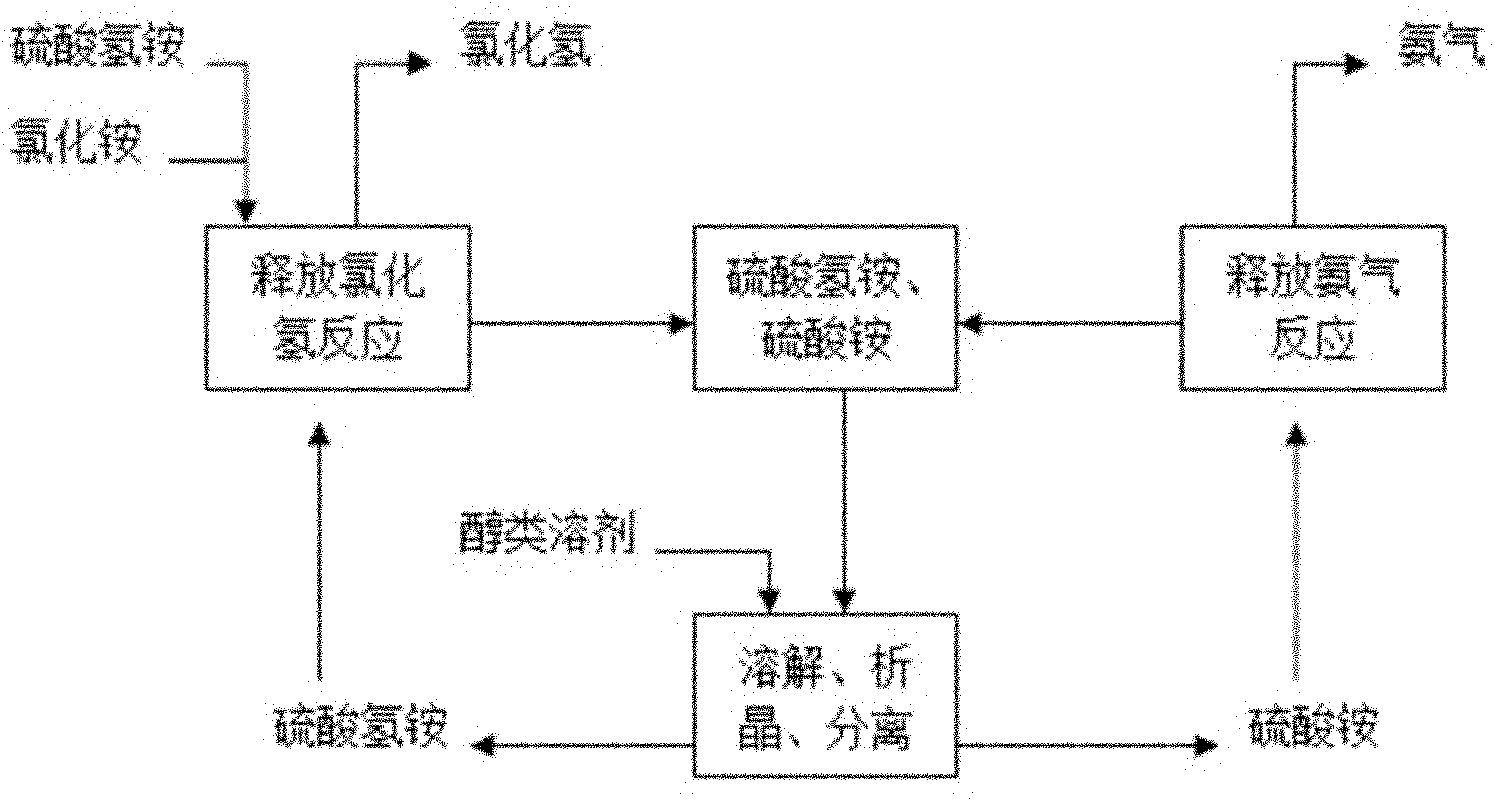

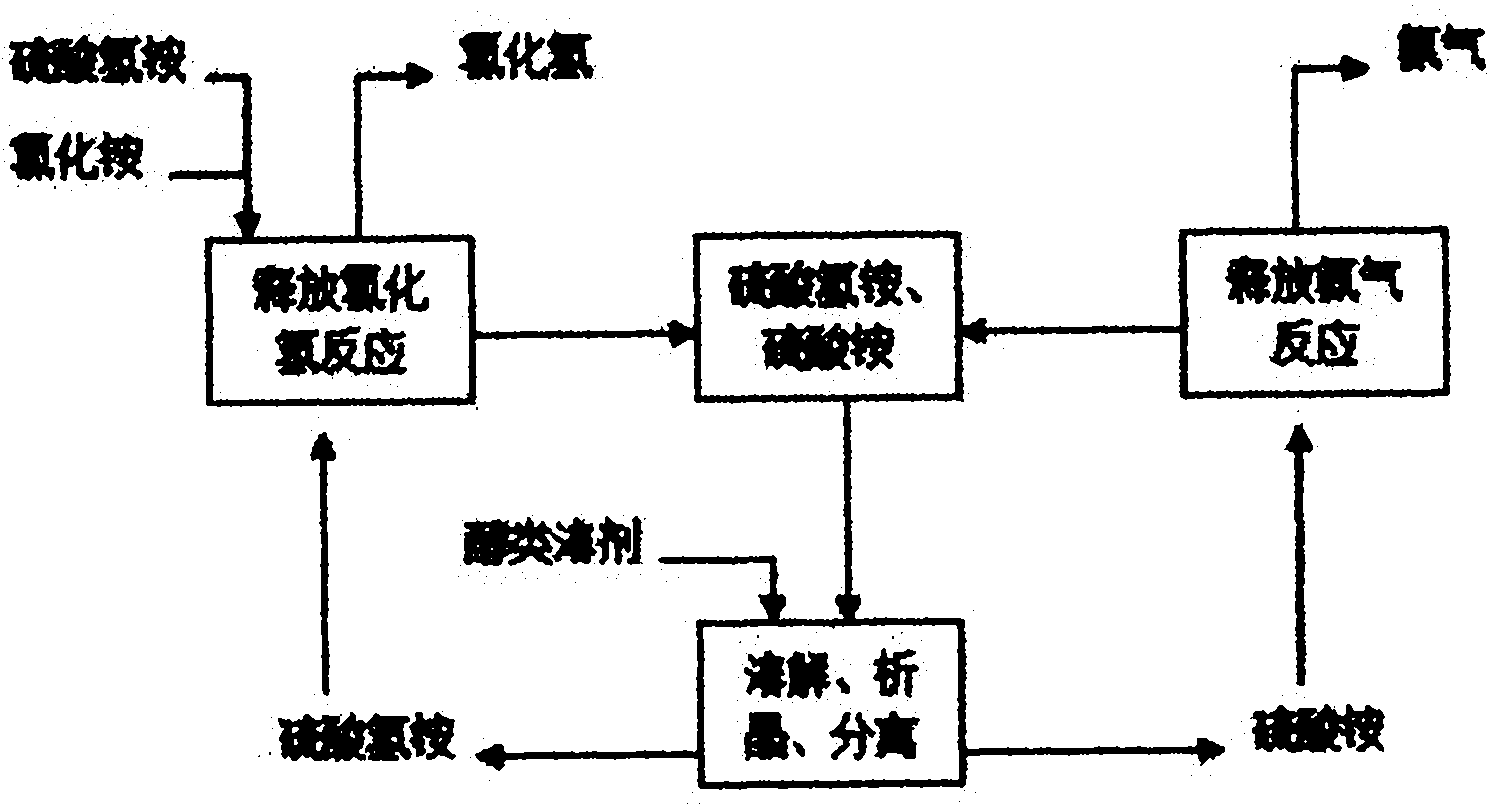

[0034] like figure 1 Shown, a kind of ammonium chloride produces the method for hydrogen chloride and ammonia, comprises the following steps:

[0035] 1. Acid release reaction process

[0036] During the acid release reaction, first add the intermediate separation inorganic acidic solvent ammonium bisulfate to the reaction kettle, and then add the dried and sieved solid ammonium chloride and hydrogen sulfate with a particle size of 40 meshes under stirring conditions. The molar ratio of ammonium to ammonium chloride is 1:1. At this time, a large amount of hydrogen chloride gas is produced. After 2 hours of constant temperature reaction, the conversion rate of ammonium chloride reaches 90.5%. The hydrogen chloride gas produced has a purity of 91.8% without treatment and can be used after treatment In the production or preparation of high-purity hydrochloric acid in PVC, the remaining ammonium bisulfate and ammonium sulfate are crystallized and separated;

[0037] 2. Intermedi...

Embodiment 2

[0042] A method for ammonium chloride to produce hydrogen chloride and ammonia, comprising the following steps:

[0043] 1. Acid release reaction process

[0044]During the acid release reaction, first add the intermediate separation inorganic acidic solvent ammonium bisulfate to the reaction kettle, after heating up to 250°C, add the dried and sieved solid ammonium chloride with a particle size of 100 mesh, hydrogen sulfate The molar ratio of ammonium to ammonium chloride is 5:1. At this time, a large amount of hydrogen chloride gas is produced. After 2 hours of constant temperature reaction, the conversion rate of ammonium chloride reaches 91.5%. The hydrogen chloride gas produced has a purity of 93.2% without treatment and can be used after treatment In the production or preparation of high-purity hydrochloric acid in PVC, the remaining ammonium bisulfate and ammonium sulfate are crystallized and separated;

[0045] 2. Intermediate separation process

[0046] The molten m...

Embodiment 3

[0050] A method for ammonium chloride to produce hydrogen chloride and ammonia, comprising the following steps:

[0051] 1. Acid release reaction process

[0052] During the acid release reaction, first add the intermediate separation inorganic acidic solvent ammonium bisulfate to the reaction kettle, after heating up to 220°C, add the dried and sieved solid ammonium chloride with a particle size of 60 mesh, hydrogen sulfate The molar ratio of ammonium to ammonium chloride is 3:1. At this time, a large amount of hydrogen chloride gas is produced. After 2 hours of constant temperature reaction, the conversion rate of ammonium chloride reaches 90.8%. The hydrogen chloride gas produced has a purity of 92.6% without treatment and can be used after treatment In the production or preparation of high-purity hydrochloric acid in PVC, the remaining ammonium bisulfate and ammonium sulfate are crystallized and separated;

[0053] 2. Intermediate separation process

[0054] The molten m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com