Method for recycling carbon fiber wastewater

A carbon fiber and waste water technology, applied in the field of water treatment, can solve the problems such as difficulty in discharging waste water up to standard, failure to achieve treatment effect, damage to microbial membrane, etc., and achieve the effect of significant degradation of organic matter, alleviation of water pollution, and improvement of ecological environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

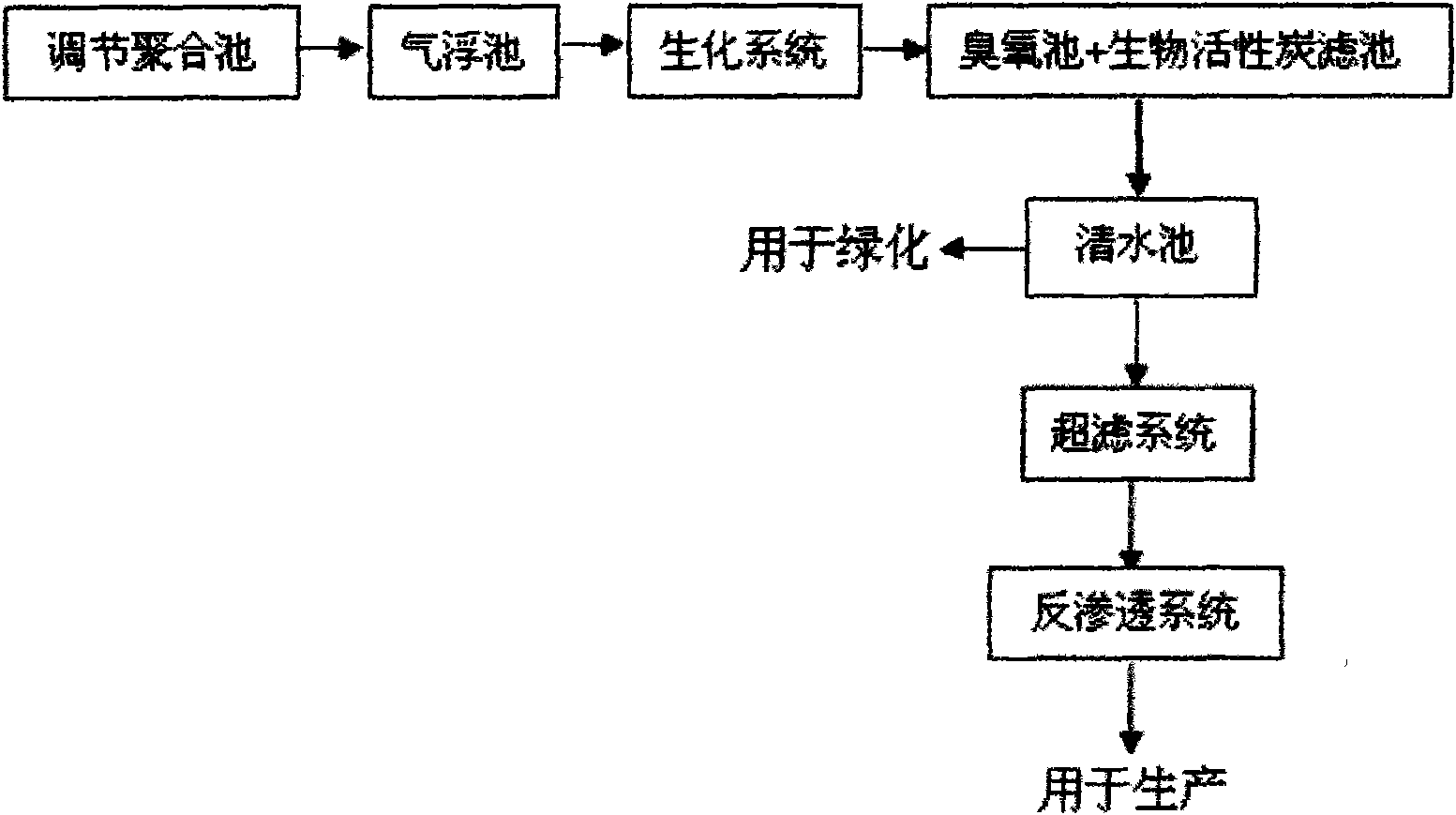

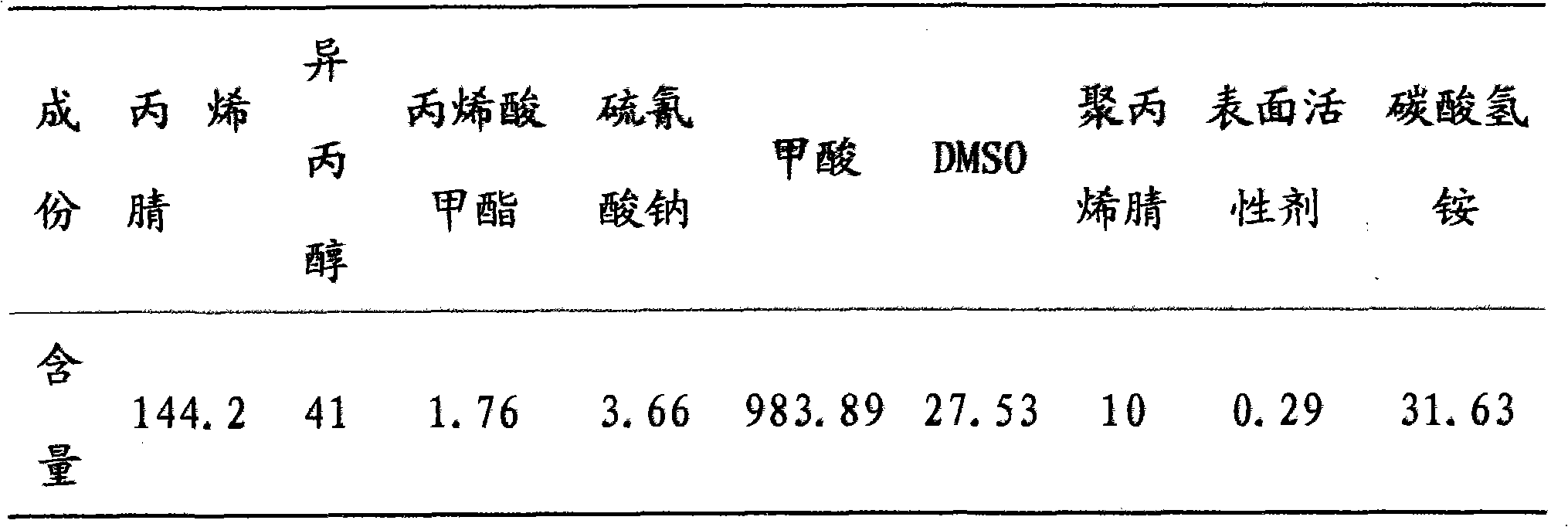

[0018] according to figure 1 The carbon fiber wastewater treatment and reuse process is used to manufacture carbon steel anti-corrosion treatment equipment and connect pipelines. The effective volume and hydraulic retention time of the pool are shown in Table 1. Prepare waste water (ie raw water) before treatment according to the material composition and concentration in Table 2, and its COD value is about 750mg / L.

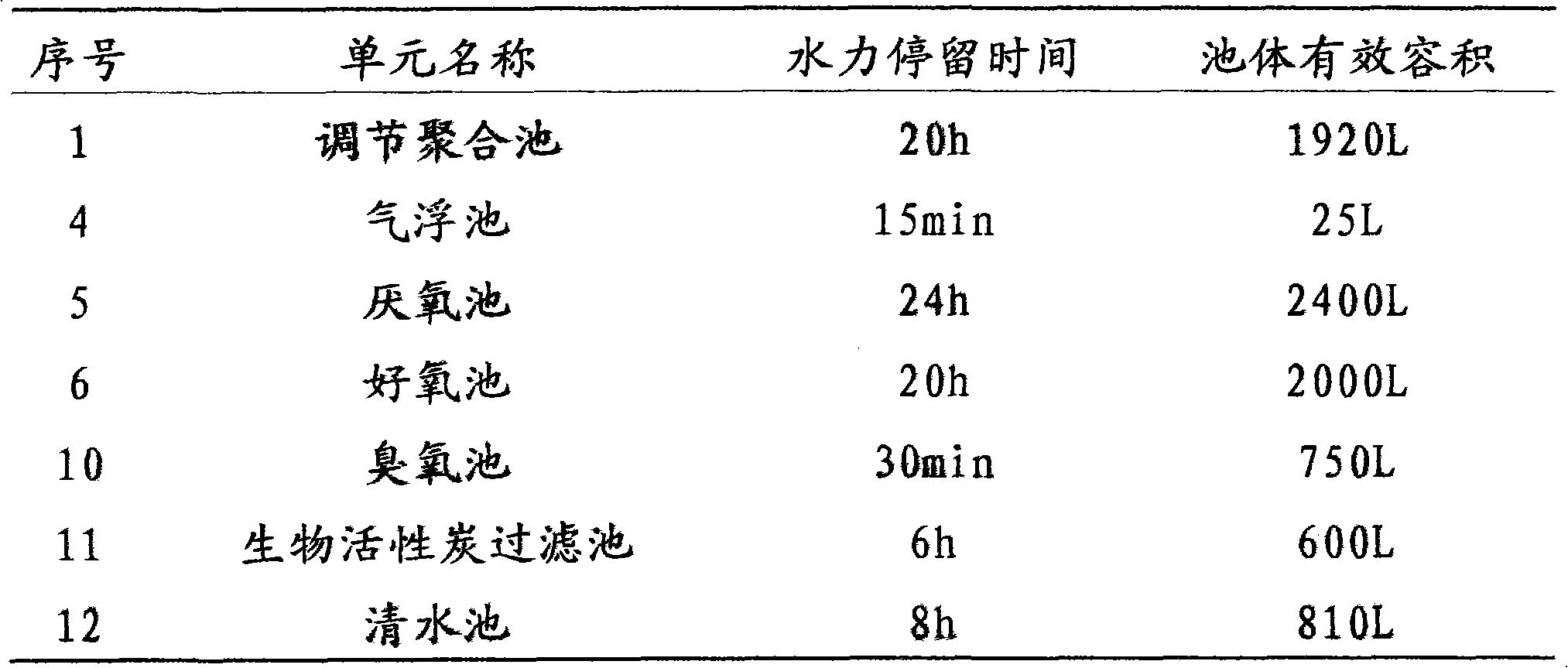

[0019] Table 1 Overview of process units

[0020]

[0021] Table 2 Concentration of organic matter in raw water (unit: mg / L)

[0022]

[0023] The wastewater first enters the adjustment polymerization tank for treatment, and the pH value is adjusted to 5.2;

[0024] Introduce the effluent from the adjusted polymerization tank into the air flotation tank to remove suspended solids, and the residence time is 15 minutes;

[0025] The effluent from the air flotation tank is introduced into the biochemical system, and enters the anaerobic tank and the aerobic ...

Embodiment 2

[0030] The substance concentration in Example 1 was increased by 2 times, and the experiment was repeated according to the steps of Example 1 to obtain a COD value of 29 mg / L and an ammonia nitrogen value of 3 mg / L in the effluent.

Embodiment 3

[0032] The water produced in Example 2 enters the ultrafiltration+reverse osmosis system, wherein the ultrafiltration membrane adopts the UNA-620A membrane of Asahi Kasei, the cut-off diameter is 0.1 μm, and the design flux is 60L / (m 2 · h), the BW365-FR membrane of Dow was used for reverse osmosis, the COD in the effluent was not detected, and the ammonia nitrogen value was 0.5mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cod value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com