Method for preparing conductive polymer/silsesquioxane composite electrode material

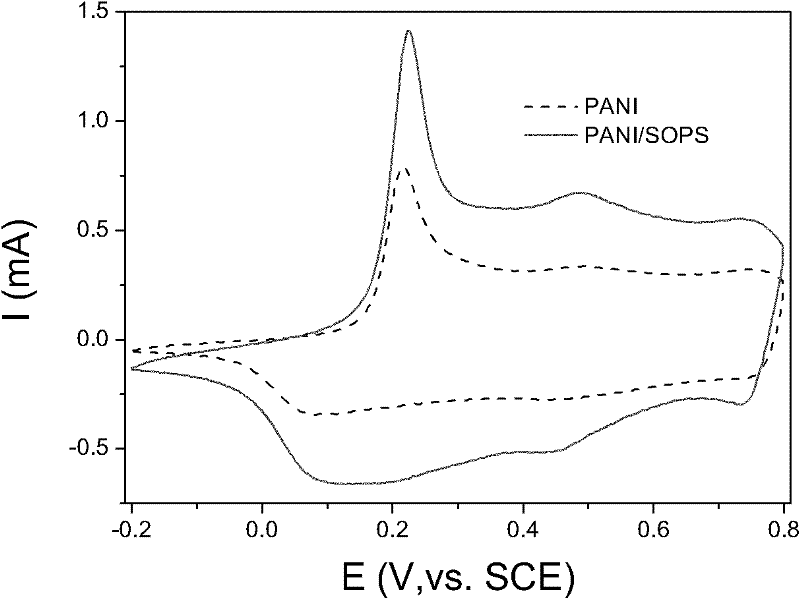

A silsesquioxane, conductive polymer technology, applied in electrolytic capacitors, circuits, capacitors, etc., can solve the problems of increasing the charge and discharge response speed, exceeding the surface charge migration rate of electrode materials, etc. The effect of circulation and low internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

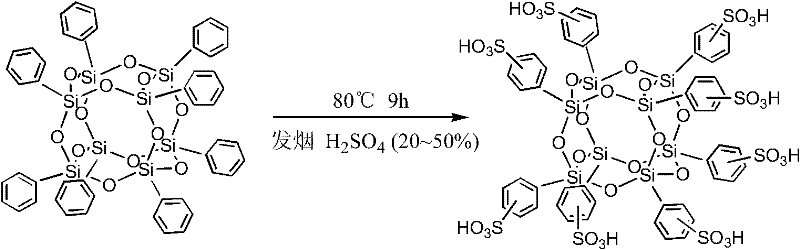

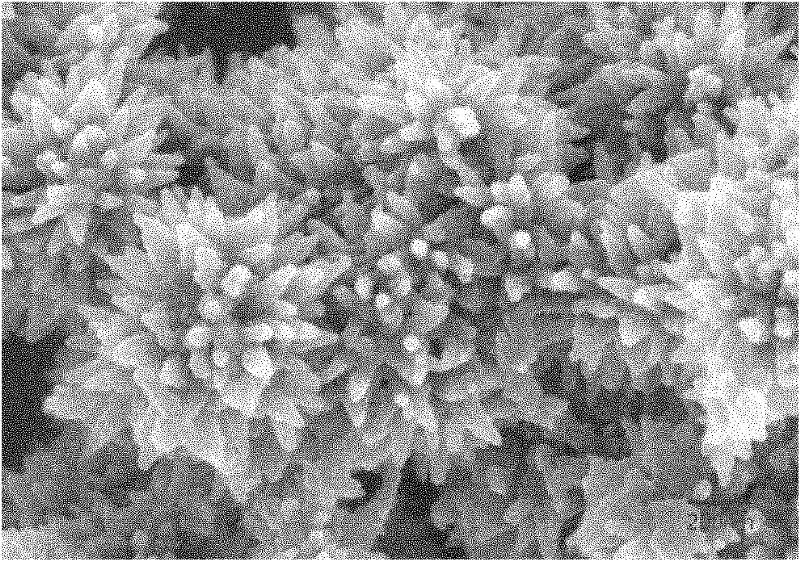

[0024] (1) Preparation of sulfonated silsesquioxane. Add 30mL of concentrated sulfuric acid into a 100mL three-neck flask, add 3g of octaphenylsilsesquioxane, and stir evenly with a magnet; slowly add 15mL of 20% oleum dropwise; after the dropwise addition, slowly raise the temperature to 90°C and keep for 6h. Filter out the sulfonated silsesquioxane with a No. 4 sand core funnel, and wash with deionized water until the filtrate is neutral. Vacuum dry at room temperature for later use. (2) Disperse the sulfonated silsesquioxane in 30mL 1mol L -1 In sulfuric acid aqueous solution, ultrasonic dispersion is uniform, and its concentration is 1.0%; (3) add aniline monomer to above-mentioned H 2 SO 4 In aqueous solution, its concentration is 0.1mol L -1 , sonicate for 1h to make the aniline monomer and the chemically modified silsesquioxane fully act; (4) After cooling the above mixed solution to 0°C, quickly add 0.684g of ammonium persulfate, stir well, and keep the mixed solut...

Embodiment 2

[0026] (1) Preparation of sulfonated silsesquioxane. Add 30mL of concentrated sulfuric acid into a 100mL three-neck flask, add 3g of octaphenylsilsesquioxane, and stir evenly with a magnet; slowly add 10mL of 30% oleum dropwise; after the dropwise addition, slowly raise the temperature to 60°C and keep for 6h. Filter out the sulfonated silsesquioxane with a No. 4 sand core funnel, and wash with deionized water until the filtrate is neutral. Vacuum dry at room temperature for later use. (2) Disperse the sulfonated silsesquioxane in 30mL 1mol L -1 In sulfuric acid aqueous solution, ultrasonic dispersion is uniform, and its concentration is 0.75%; (3) add aniline monomer to above-mentioned H 2 SO 4 In aqueous solution, its concentration is 0.1mol L -1 , sonicate for 1h to make the aniline monomer and the chemically modified silsesquioxane fully act; (4) After cooling the above mixed solution to 0°C, quickly add 0.684g of ammonium persulfate, stir well, and keep the mixed solu...

Embodiment 3

[0028] (1) Preparation of sulfonated silsesquioxane. Add 30mL of concentrated sulfuric acid into a 100mL three-necked flask, add 3g of dodecylsilsesquioxane, and stir evenly with a magnet; slowly add 8mL of chlorosulfonic acid dropwise; after the dropwise addition, keep at room temperature for 12 hours. Filter out the sulfonated silsesquioxane with a No. 4 sand core funnel, and wash with deionized water until the filtrate is neutral. Vacuum dry at room temperature for later use. (2) Disperse the sulfonated silsesquioxane in 30mL 1mol L -1 In sulfuric acid aqueous solution, ultrasonic dispersion is uniform, and its concentration is 1.0%; (3) add aniline to above-mentioned H 2 SO 4 In aqueous solution, its concentration is 0.1mol L -1, sonicate for 1h to make the aniline monomer and the chemically modified silsesquioxane fully act; (4) After cooling the above mixed solution to 0°C, quickly add 0.684g of ammonium persulfate, stir well, and keep the mixed solution at 0°C (5) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com