Method for eliminating internal stress of crankshaft through harmonic spectrum vibration aging treatment

A technology of harmonic vibration and aging treatment, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of engine crankshaft manufacturing and use that have not been reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] 1. Spectrum harmonic aging equipment : One set of navigator spectrum harmonic aging expert system; one set of LH6505 exciter; one set of bow clamp.

[0018] 2. Process flow: blank - rough machining (drilling center hole, turning spindle and connecting rod journal, leaving a margin of 0.40mm on one side) - spectrum harmonic aging - finishing (turn drilling, grinding) - Nitriding - Polishing.

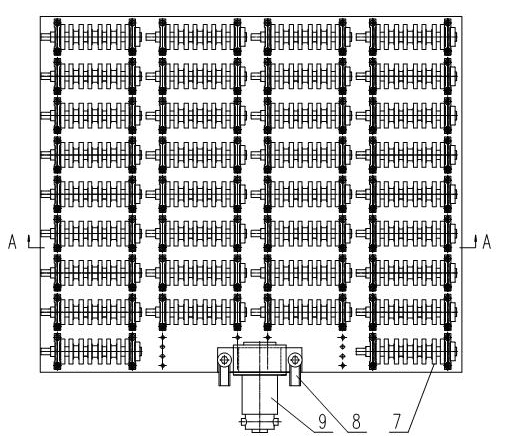

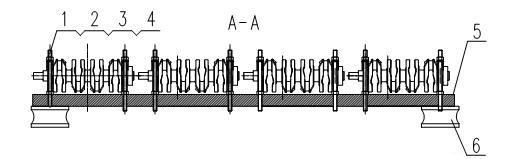

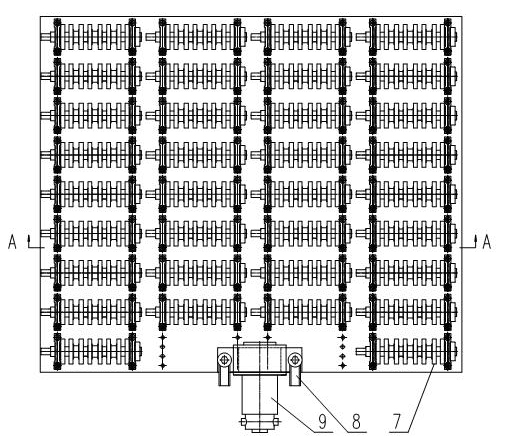

[0019] 3. This kind of workpiece adopts platform auxiliary clamping, and 4 rubber pads are used to support the platform stably. 34 crankshafts are clamped each time, and the vibration exciter is rigidly clamped on the platform with a bow clamp for processing.

[0020] 4. On-site support and clamping. See figure 1 , figure 2 . A total of 34 crankshafts 7 are clamped on a square platform 5. Each crankshaft is fixed on the platform by four sets of fixing parts consisting of a screw 1, a nut 2, a V-shaped block 3 and a pressure plate 4. The rubber shock absorber 6 is located unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com