Method for preparing DSSC (Dye Sensitized Solar Cell) with double-helix structure

A solar cell, double helix structure technology, applied in photosensitive devices, circuits, photovoltaic power generation, etc., can solve the limitations of breakthrough progress and expansion of application fields, dye-sensitized solar cells have good low-light performance, low light utilization, etc. problems, to achieve the effect of improving long-term stability, promoting the process of industrialization, and good low-light performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1: Preparation of photoanode

[0027] 1) Preparation of titania sol precursor solution: first mix 0.1 mol titanyl sulfate and water at a ratio of 2 mol / L titanium ion concentration at 15-20 ° C, then let stand for 12 hours to clarify, filter and mix with 1 mol / L ammonia water The co-precipitation was titrated into 200ml deionized water until the pH value was equal to 7, and the obtained white precipitate was washed by centrifugation until it was washed with Ba(NO 3 ) 2 The solution had no detectable residual SO 4 2- ions, and then at 60°C, the white precipitate was pressed by Ti 4+ : oxalic acid: the molar ratio of hydrogen peroxide is 1: 5: 5 to dissolve, then the pH value of this solution is adjusted to 7-8 with ammonia water, after standing for 10 hours, the titanium dioxide sol precursor solution is obtained;

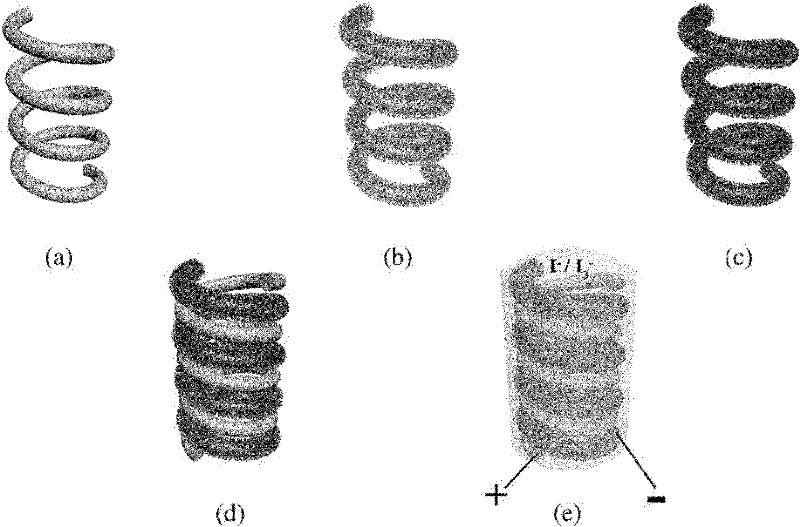

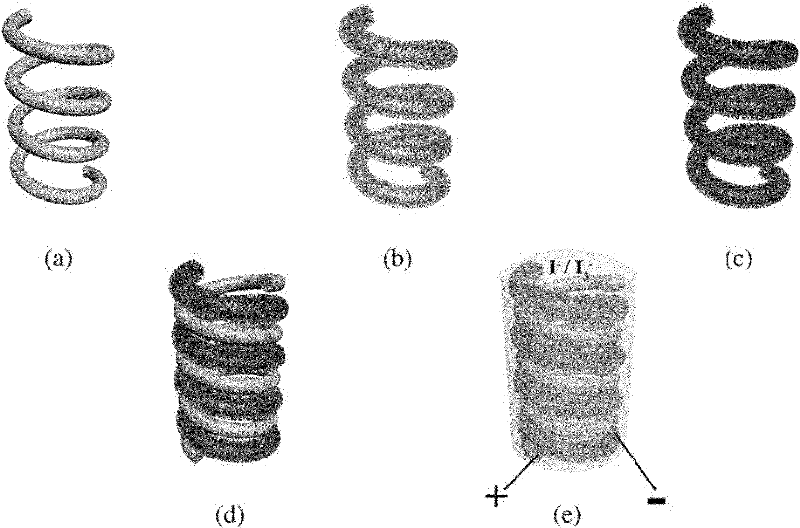

[0028] 2) The helical Ti anode (such as figure 1 As shown in (a), it was ultrasonically treated three times with ethanol and acetone respectively, ...

Embodiment 2

[0034] Step 1: Preparation of photoanode

[0035] 1) Preparation of titania sol precursor solution: first, 0.1mol of TiCl 4 with 400ml of 1mol / L NaHCO 3 Co-precipitate and titrate the white precipitate obtained in 100ml deionized water, centrifuge and wash three times, and then press Ti 4+ : citric acid: the molar ratio of hydrogen peroxide is 1: 5: 6 to dissolve, then the pH value of this solution is adjusted to 7-8 with ammonia water, after standing for 15 hours, the titanium dioxide sol precursor solution is obtained;

[0036] 2) The helical Ti anode was ultrasonically treated three times with ethanol and acetone respectively, then placed in the titanium dioxide sol precursor solution, hydrothermally treated in a hydrothermal kettle at 250°C for 8h; then heat-treated at 200°C for 4h to obtain a titanium dioxide-coated The pretreatment photoanode is then soaked in the dye (the dye is selected as black dye), soaked for 24h and then taken out to wash off the dye on the surfa...

Embodiment 3

[0042] Step 1: Preparation of photoanode

[0043] 1) Preparation of titania sol precursor solution: first titrate the white precipitate obtained in 200 ml of deionized water with 0.1 mol of titanium sulfate and 400 ml of 1 mol / L NaOH co-precipitation, centrifuge and wash three times, and then at 80° C. Ti 4+ : tartaric acid: the mol ratio of hydrogen peroxide is 1: 10: 10 is dissolved, and then the pH value of this solution is adjusted to 7-8 with ammoniacal liquor, promptly obtains titania sol precursor solution after standing for 12 hours;

[0044]2) The spiral Ti anode was ultrasonically treated three times by ethanol and acetone respectively, then placed in the titanium dioxide sol precursor solution, and hydrothermally treated in a hydrothermal kettle at 160°C for 18h; then heat-treated at 200°C for 4h to obtain a titanium dioxide-coated The pretreatment photoanode, then soak it in the dye (dye selection N719), after soaking for 24h, take out the dye on the surface and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com