Natural gas hydro-cracking metallurgical method and equipment

A technology of natural gas cracking and hydrogen metallurgy, applied in chemical instruments and methods, hydrogen, hydrogen separation, etc., can solve problems such as breakthroughs in pollution treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

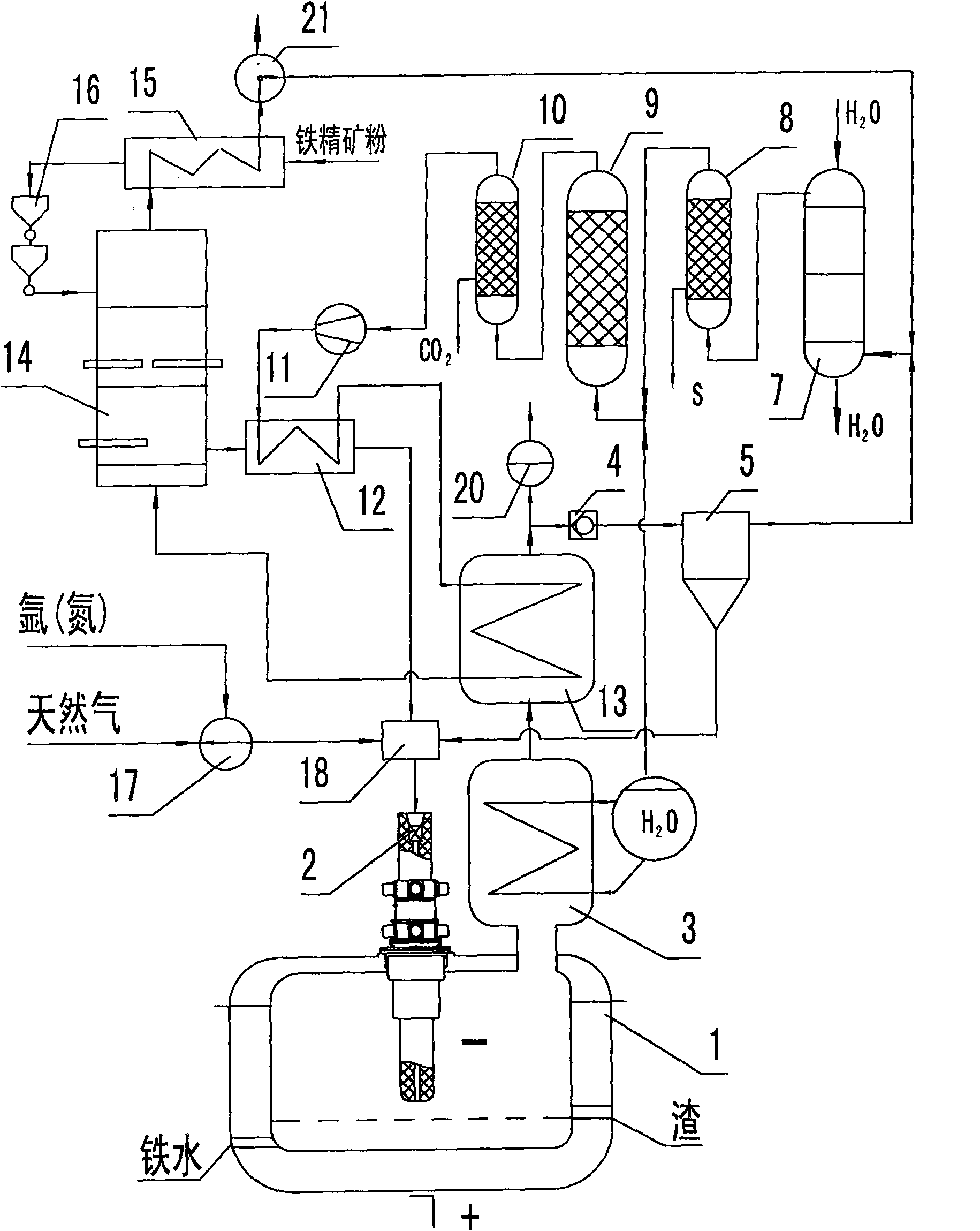

Embodiment 1

[0059] "Basic implementation model of natural gas cracking hydrogen metallurgy" (attached figure 1 ), the basic smelting process steps are as above, and the technical parameters are: in step (1), produce 1000Kg molten iron with 120~160Kg natural gas, and input natural gas and sponge iron to the smelting and cracking furnace in the ratio of 120~160Kg natural gas; Sponge iron with a density greater than 70%, and according to the changes in the composition and pressure of the tail gas of the metallurgical cracking furnace and fluidized bed caused by the change in the chemical composition of the raw materials used, ensure that the working pressure is within the required range, and timely control the amount of natural gas added to the smelting cracking furnace and fluidization The reduction degree of the bed sponge iron can realize the balance between the supply and demand of hydrocarbons and the stability of the system pressure in the whole metallurgical process, so as to ensure th...

Embodiment 2

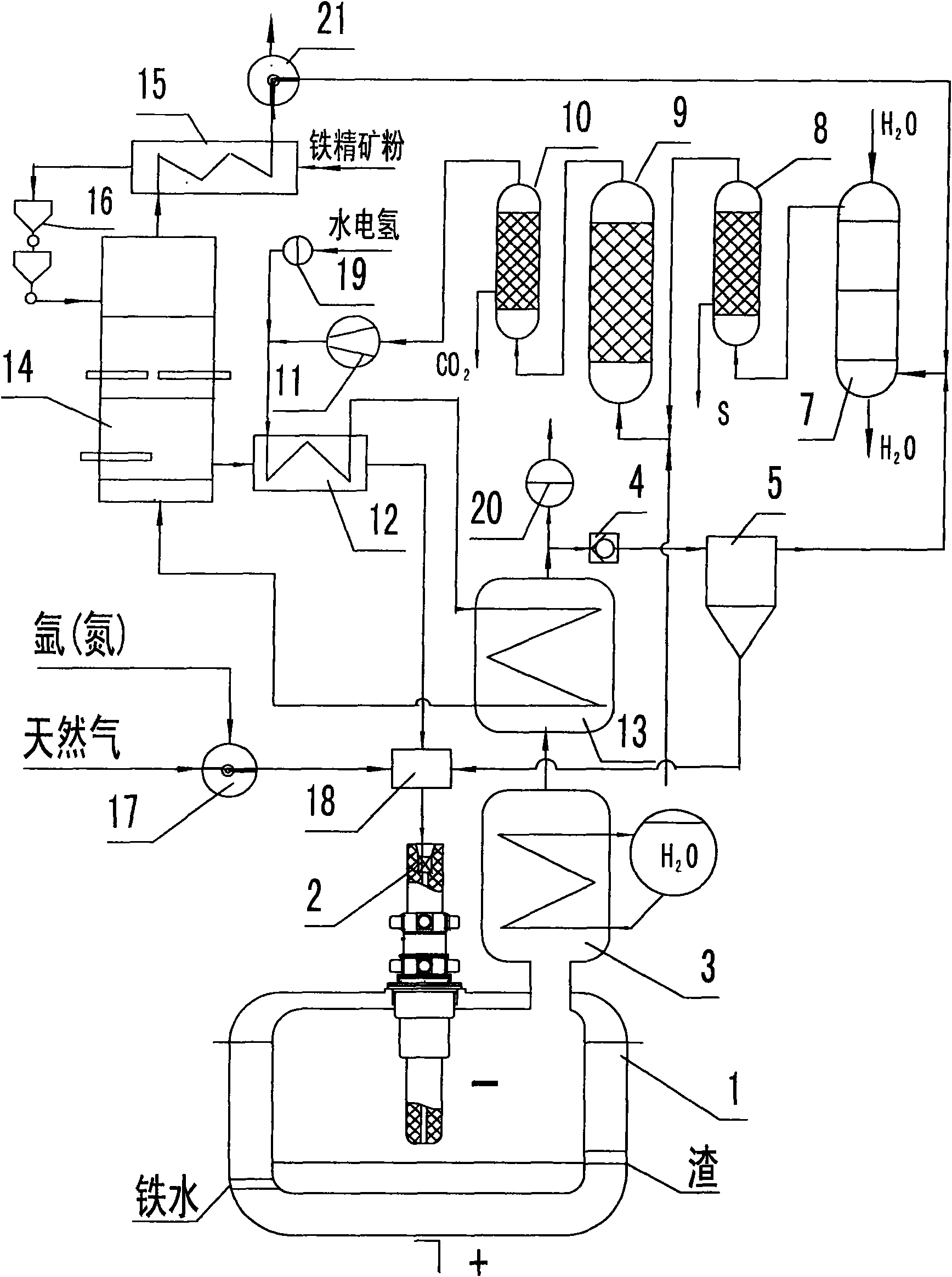

[0066] This process is the "implementation mode of hydrogen supplementation in natural gas cracking hydrogen metallurgy", and the smelting process steps are as follows figure 2 Shown, process parameter is: in step (1) with 80~140Kg natural gas: 1000Kg molten iron, the ratio input natural gas and sponge iron, in step (2), also must open source from the outside of this system, add by shut-off valve 19 5-20Kg of industrial pure hydrogen (the most ideal is the hydropower hydrogen produced and stored by full-load electrolyzed water during the peak period of hydropower flood water and the low power consumption period of evening holidays) and the industrial pure hydrogen obtained by separation of tail gas from smelting and cracking furnaces. Production of sponge iron with reduction degree > 90% in chemical bed;

[0067] Since the amount of natural gas added in step (1) is biased towards the low end of the range, the carbon produced by cracking can only basically meet the needs of th...

Embodiment 3

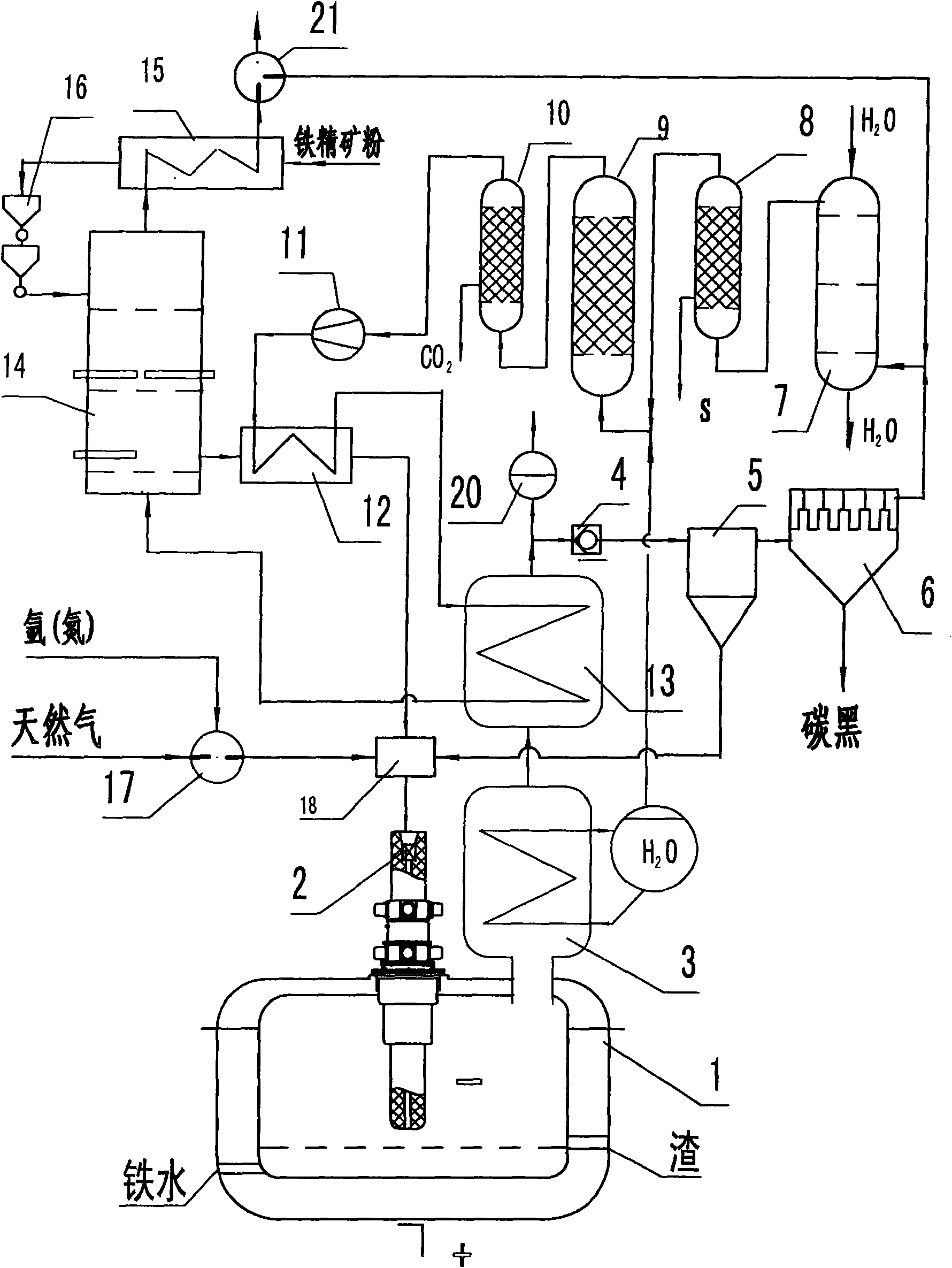

[0071] This process is " natural gas cracking hydrogen metallurgical carbon black co-production implementation mode ", and smelting process step is as shown in accompanying drawing 3, and process parameter is: in step (1) with 150~180Kg natural gas: 1000Kg molten iron, the proportioning input natural gas and Sponge iron, the carbon black bag filter 6 commonly used in the carbon black industry is added in step (2). The black is attached to the filter bag, and the anti-suction automatic shaking device is used to make the filter bag produce an imbibition effect, shake the carbon black from the filter bag, and send it to the carbon black processing workshop for granulation to produce carbon black products. Pass through the filter bag and flow into the next process for purification, desulfurization and CO conversion, and produce sponge iron with a reduction degree of >90%.

[0072] The characteristic of this process is that the amount of natural gas added is high-end, and the hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com