High-filling high-heat distortion temperature polypropylene composite material and preparation method thereof

A composite material and deformation temperature technology, which is applied in the fields of high-filling and high-heat-distortion-temperature polypropylene composite materials and their preparation and components, can solve the problems of high heat-distortion temperature and complicated process of modified polypropylene, and improve heat aging resistance. , the effect of increasing solubility, improving heat resistance and heat distortion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

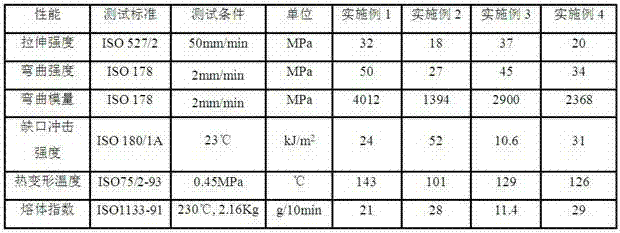

Embodiment 1

[0036] A high-filling high heat distortion temperature polypropylene composite material is composed of the following raw materials in weight percentage: polypropylene A (brand: K7726H, Sinopec Yanshan Petrochemical Company) 30%; polypropylene B (brand: 140 powder, Sinopec Co., Ltd. Maoming Branch) 8%; elastomer 10%; talcum powder 50%; composite antioxidant 1.5%; nucleating agent 0.2%; processing aid 0.3%.

[0037]The composite antioxidant is preferably A+B type, wherein A is 1,3,5-tri(3,5-di-tert-butyl-4-hydroxybenzyl)-s-triazine-2,4,6 -(1H,3H,5H ) triketone (Ningbo Jinhai Yabao Chemical Co., Ltd.) 1.0%, B is tris(2,4-di-tert-butylphenyl)phenylphosphite (Ningbo Jinhai Yabao Chemical Co., Ltd.) 0.25% and tetrakis (β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester (Beijing Yizhong Weiye Chemical Co., Ltd.) 0.25%; the elastomer is ethylene-butene Copolymer (Shenzhen Yongcheng Plastic Chemical Co., Ltd.); the talc powder is AH-3000N1 (Liaoning Aihai Talc Co....

Embodiment 2

[0043] A high-filling high heat distortion temperature polypropylene composite material is composed of the following raw materials in weight percentage: polypropylene A (brand: K7760, Sinopec Yanshan Petrochemical Company) 70%; polypropylene B (brand: 300 powder, Sinopec Co., Ltd. Maoming branch) 5%; elastomer 14%; talcum powder 10%; composite antioxidant 0.7%; nucleating agent 0.1%; processing aid 0.2%.

[0044] The composite antioxidant is preferably A+B type, wherein A is 0.5% of tetrafunctional glycidylamine epoxy resin (Guangzhou Rongsheng Chemical Co., Ltd.), and B is bis(2.4-di-tert-butylphenyl ) pentaerythritol diphosphite (Ningbo Jinhai Yabao Chemical Co., Ltd.) company) 0.1%. The elastomer is 7% of ethylene-butene copolymer and 7% of ethylene-propylene-octene terpolymer (Shanghai Bading Trading Co., Ltd.). The talc powder is AH-3000N9 (Liaoning Aihai Talc Co., Ltd.). The nucleating agent is NA-11 (Youdi Trading (Shanghai) Co., Ltd.). Described processing aid is m...

Embodiment 3

[0050] A high-filling high heat distortion temperature polypropylene composite material is composed of the following raw materials in weight percentage: polypropylene A (brand: AP3N, American Exxon Chemical Jiangmen Co., Ltd.) 60%; polypropylene B (brand: 300 powder ) 8%; talcum powder 30%; compound antioxidant 1.3%; nucleating agent 0.3%; processing aid 0.4%.

[0051] The composite antioxidant is preferably A+B type, wherein A is 1.0% of tetrafunctional glycidylamine epoxy resin (Guangzhou Rongsheng Chemical Co., Ltd.), and B is di(eighteenteen) thiodipropionate Ester (Ningbo Jinhai Yabao Chemical Co., Ltd.) 0.2% and tetrakis (β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester (Beijing Yizhong Weiye Chemical Co., Ltd.) 0.1%. The talc powder is AH-1250 (Liaoning Aihai Talc Co., Ltd.). Described nucleating agent is HPN-68L (American Milliken chemical company). The processing aid is composed of 0.2% polyethylene wax, 0.1% ethylene bis stearamide and 0.1% c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com