Boron carbide composite materials

A composite material and boron carbide technology, which is applied in the field of manufacturing boron carbide composite materials, can solve problems such as increasing residence time, and achieve the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

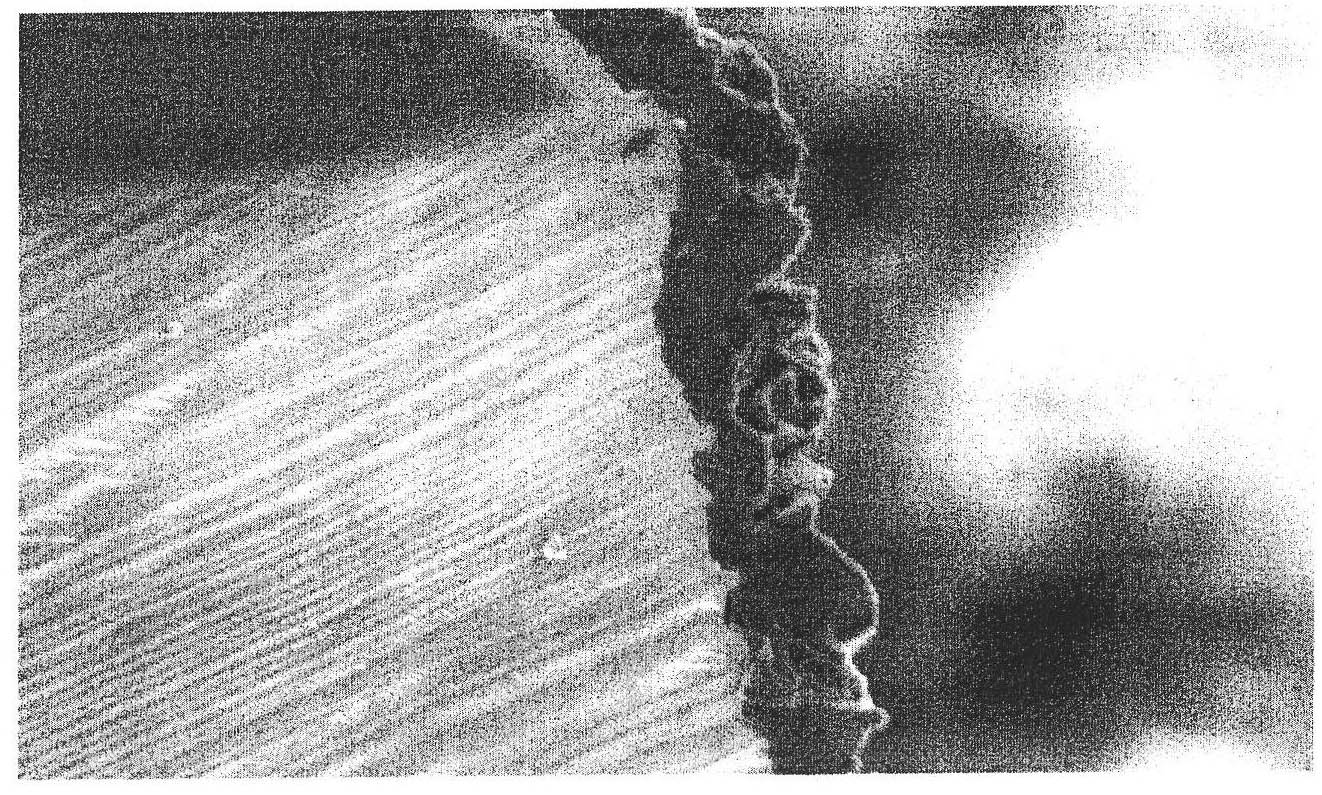

[0081] According to the method taught in WO05017227, a quantity of diamond particles having an average size between about 10 and 20 microns is coated with a coating comprising boron and carbon. Diamond particles were mixed with a powder containing a 50:50 mixture of boron and boric acid to form a layer of granular material which was placed in a tube furnace. The layer was heat treated under an argon atmosphere using the following temperature cycle:

[0082] ●Raise the temperature to 300 degrees Celsius over a period of one hour,

[0083] ●Keep it at 300 degrees Celsius for 30 minutes,

[0084] ●Then heat up to 1150 degrees Celsius in 80 minutes,

[0085] ●Keep at this temperature for 6 hours,

[0086] • and then cooled to room temperature.

[0087] The coated diamond particles were separated from excess boron and boric acid powders and then boiled in dilute nitric acid for 20 minutes to remove any remaining boron and boric acid.

[0088] The coated diamond powder was mixe...

Embodiment 2

[0100] Uncoated diamond powder was mixed with B4C particles having an average size in the range of 10 to 40 microns in a ratio of 50 wt% diamond: 50 wt% B4C. A green body was prepared as in Example 1, but without the precoated diamond particles.

[0101] The binder is substantially removed from the green body by calcination in a furnace. The green body is calcined in a furnace in contact with the silicon at a temperature sufficient to melt and infiltrate the silicon into the green body.

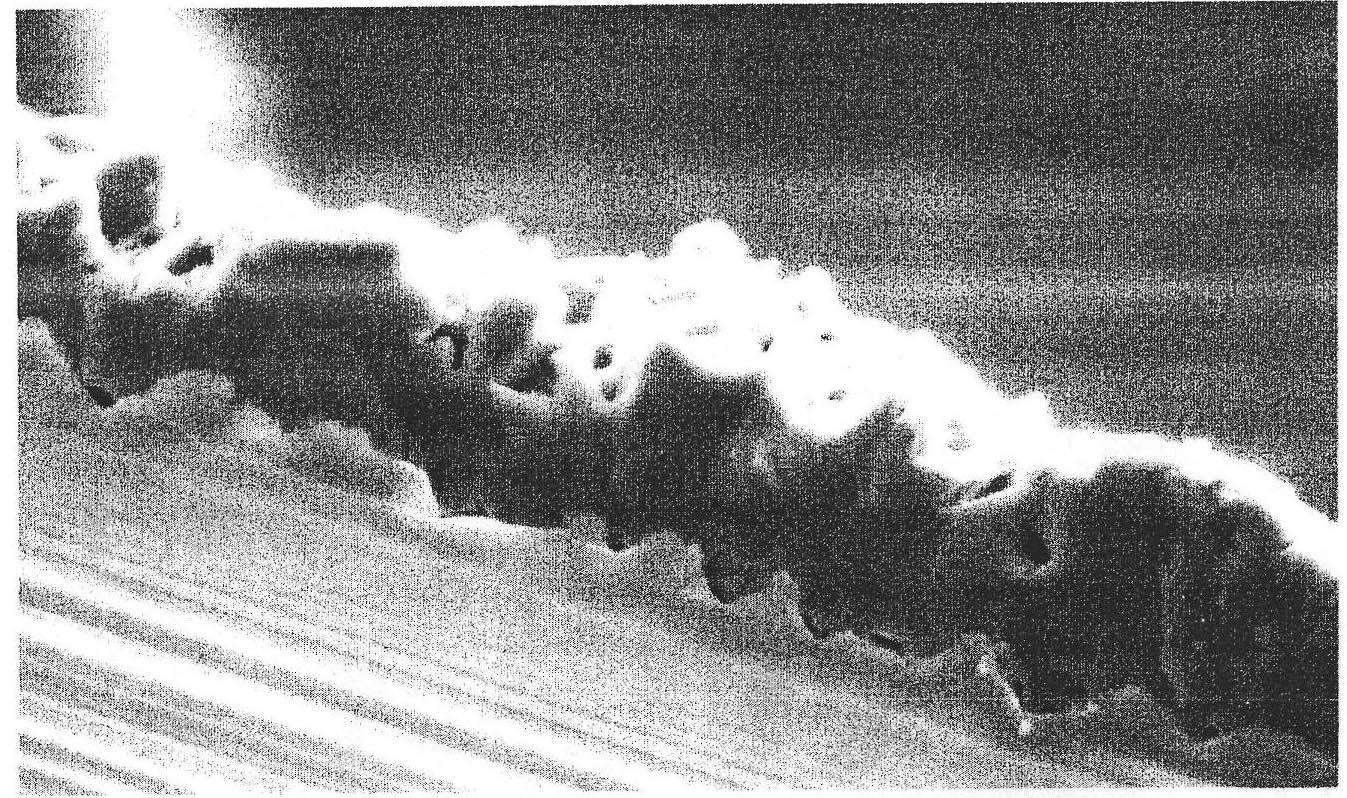

[0102] Using image analysis, it was found that the material contained about 33 wt% SiC, and the total amount of B4C and diamond was 49 wt% to 53 wt%. The sintered product had similar physical properties to the product obtained in Example 1, and the sintered product could also be easily cut by electrical discharge machining (EDM). Likewise, the sintered final composite has no visible porosity and a graphite content of less than 2% by weight.

Embodiment 3

[0104] Coated diamond particles were prepared as in Example 1.

[0105] The coated diamond and boron carbide powder were mixed in a weight ratio of 10:90, respectively. The granular material was formed into a layer by grouting, from which a rectangular green sheet was cut out with dimensions 5 cm x 5 cm x 5 mm. A binder comprising a 50 / 50 mixture of methanol and methyl isobutyl ketone (of boron carbide and diamond) at 0.5 wt. A low burn-off temperature (ie, a binder with a relatively low vapor pressure) produces the final product. The use of this "binder" results in lower internal stresses during drying and sintering, giving the article greater elasticity. The presence of the carbonaceous residue of the "binder" may enhance the sintering of boron carbide compared to attempts to sinter the boron carbide without the carbonaceous residue of the "binder".

[0106] Compact the green body under low pressure (quasi-vacuum), apply a pressure of 250 MPa, and a temperature of 1000 de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com