Method and equipment for separating cyclohexanecarboxylic acid slurry

A cyclohexane carboxylic acid and slurry separation technology, which is applied in separation methods, separation/purification of carboxylic acid compounds, filtration separation, etc., can solve the problems of increased equipment investment and operating costs, reduced catalyst activity, and poor mechanical strength. Achieve the effect of low labor intensity, improve activity and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

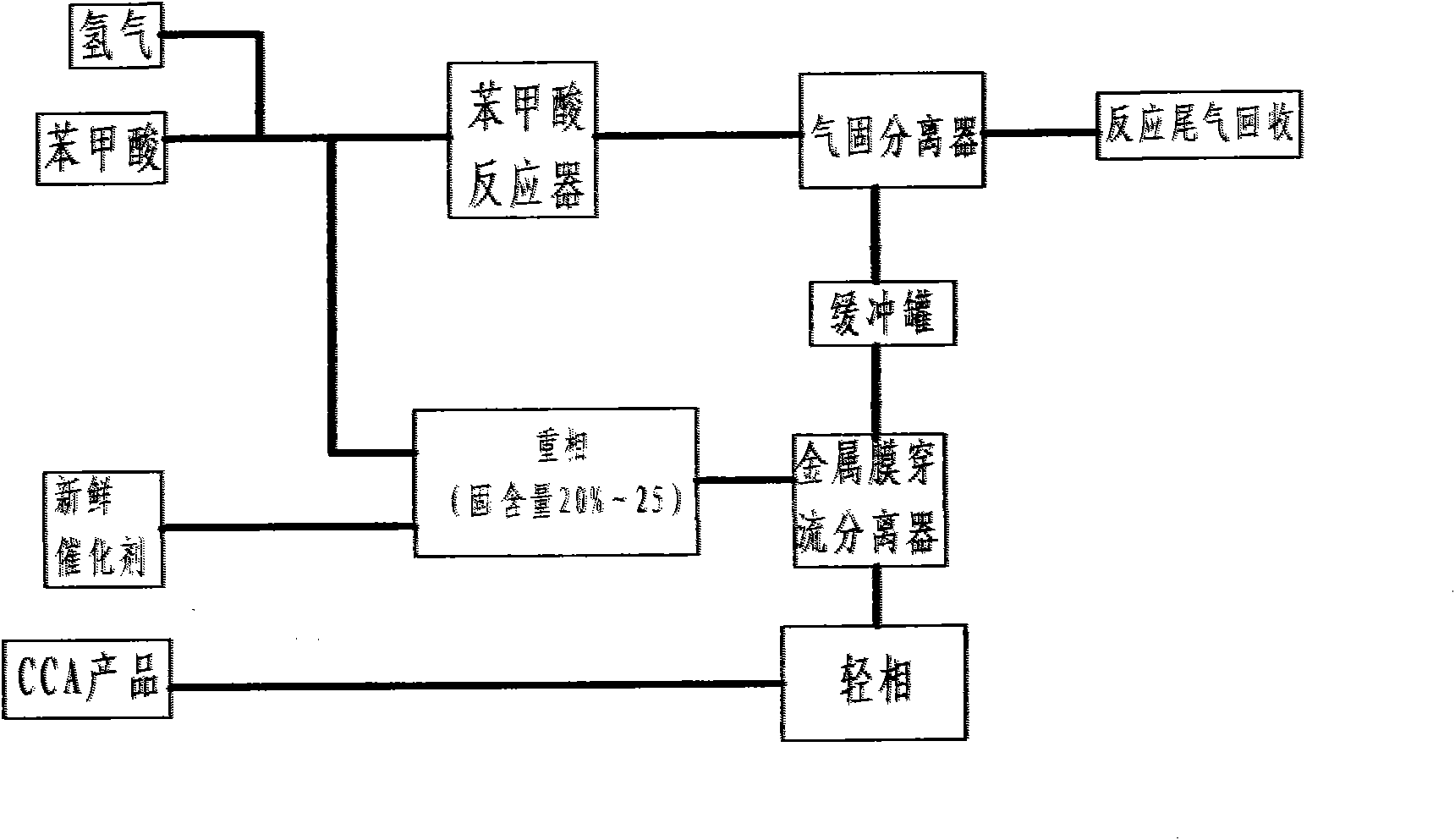

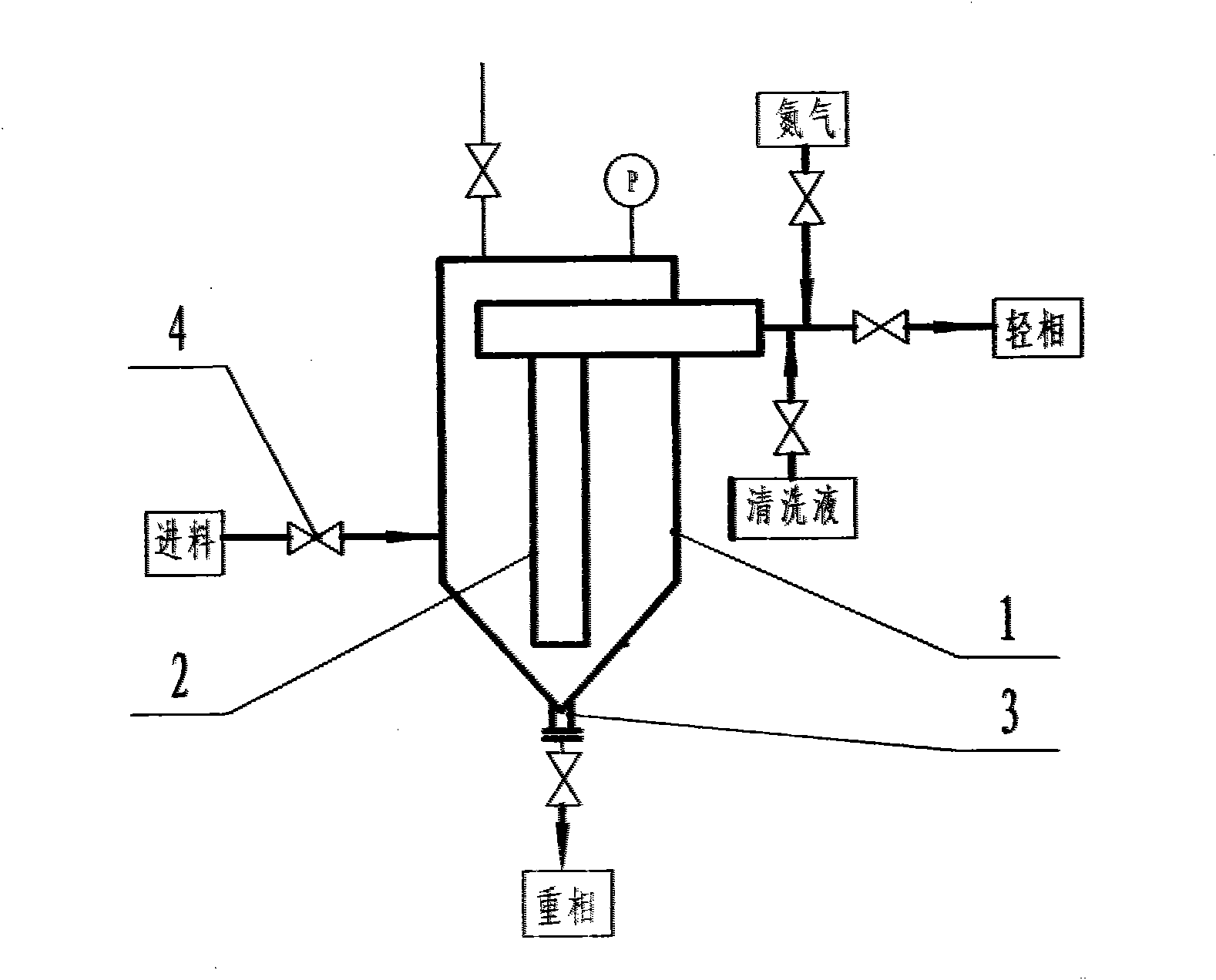

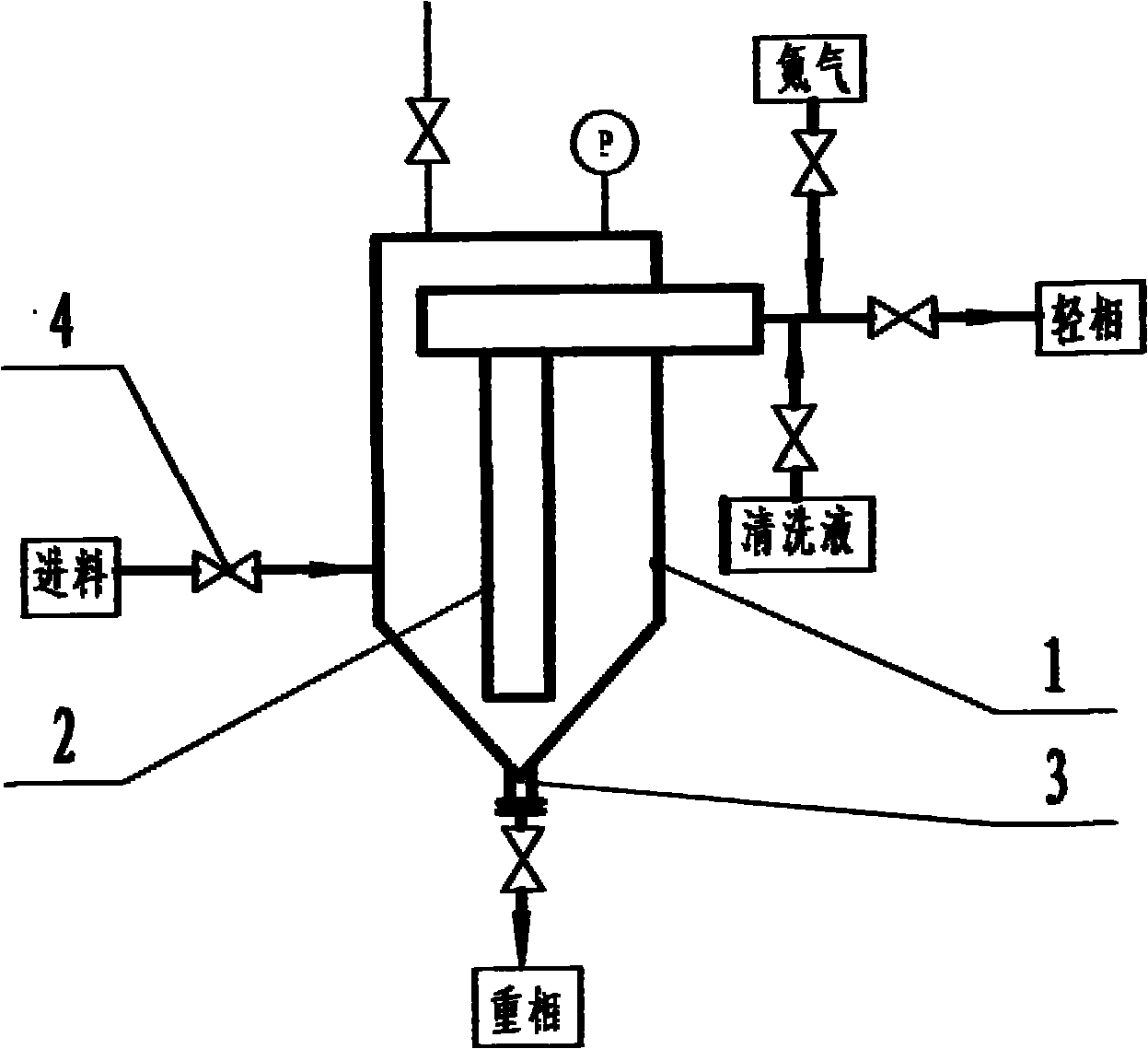

[0016] The separation system of the benzoic acid hydrogenation unit such as figure 1 Shown, including benzoic acid hydrogenation reactor, gas-solid separator, buffer tank and metal membrane separator. Such as figure 2 As shown, the separator 1 is a metal membrane flow-through separator, and the separator has a heavy phase outlet 3, a raw material inlet and a light phase outlet, and a membrane tube 2 is arranged inside the separator. The membrane tube is equipped with a stainless steel metal membrane, and the membrane pore diameter of the metal membrane is 10 μm. The light phase outlet pipe is connected with the nitrogen pipe and the clear liquid pipe, and a valve 4 is arranged on the pipe connected with the separator. The process of cyclohexane carboxylic acid slurry separation is: in benzoic acid hydrogenation reactor, in the presence of palladium carbon catalyst,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com