Pre-baked aluminum electrolysis cell based on heat pipe

An aluminum electrolytic cell and heat pipe technology, applied in the field of aluminum electrolytic cells, can solve the problems of low heat recovery efficiency, changing side heat dissipation, and occupying a large space, so as to achieve uniform temperature distribution in the cell body, slow down the flow speed, and reduce power consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

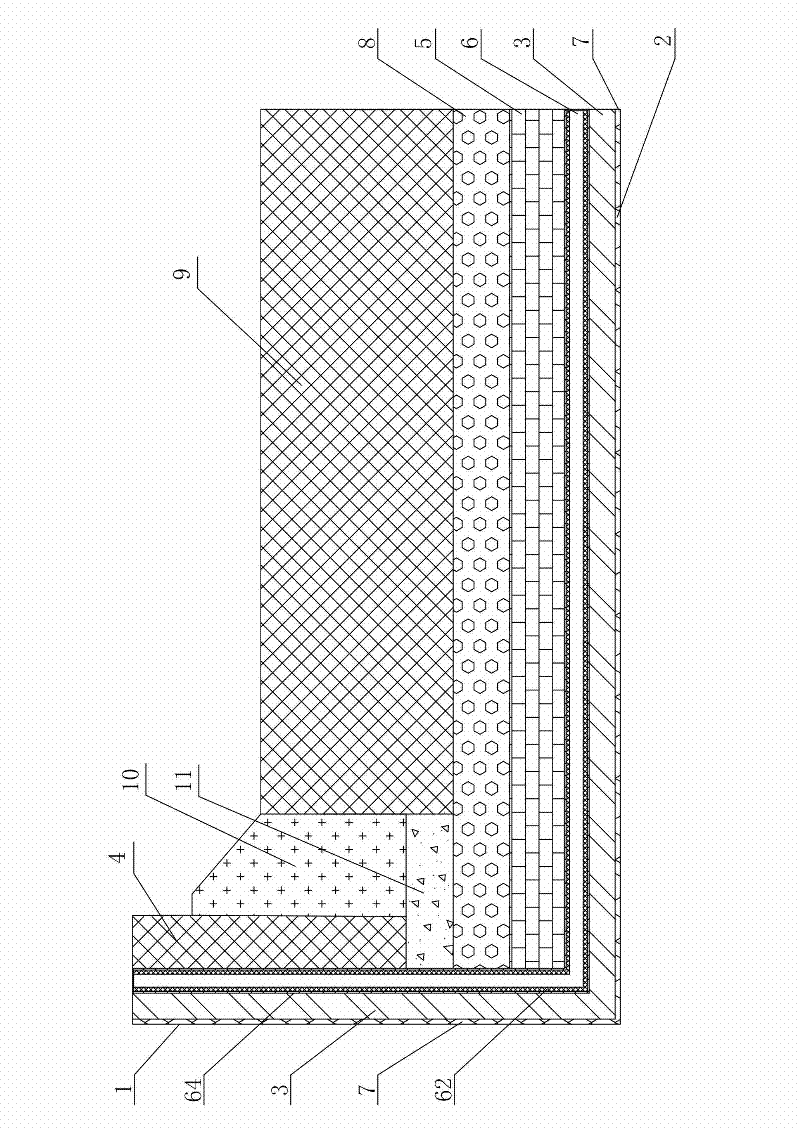

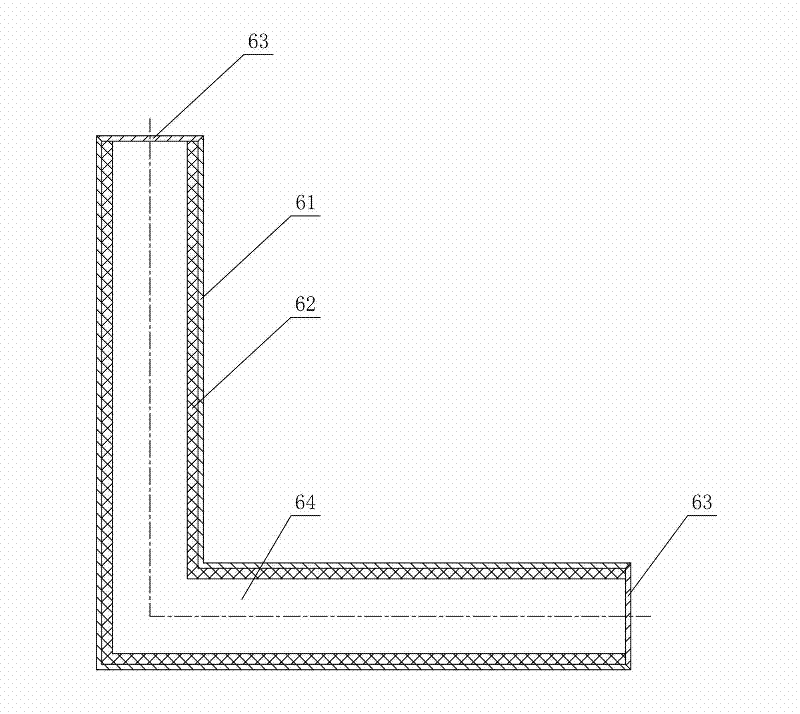

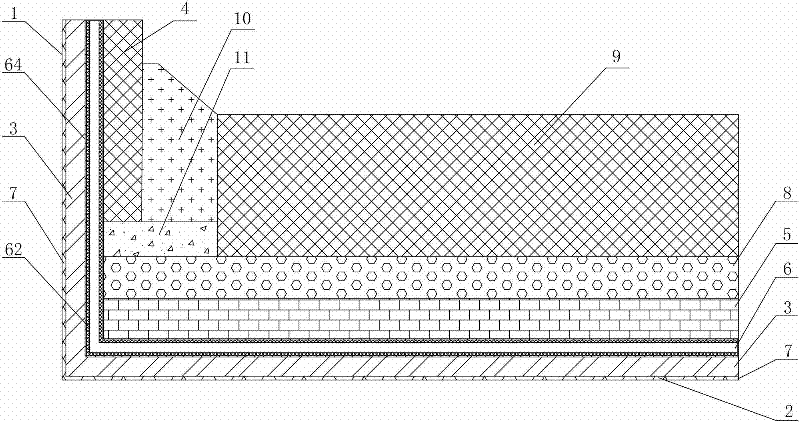

[0018] figure 1 with figure 2 It shows an embodiment of a prebaked aluminum electrolytic cell based on heat pipes of the present invention, the aluminum electrolytic cell includes a cell body, an insulating brick layer 3 is arranged outside the cell body, and the outer side of the insulating brick layer 3 is coated with microporous silicic acid Calcium board 7, the tank body is provided with side carbon block 4 on the inner side of side wall 1, and the tank body is provided with refractory brick layer 5, refractory and anti-seepage layer 8 and cathode carbon block 9 sequentially from bottom to top on the inner side of tank bottom 2, and the side The internal carbon block 4 and the cathode carbon block 9 are fixed through the tamping paste 10 and the refractory concrete layer 11, and the heat pipe 6 which can transfer the heat at the side wall 1 to the bottom 2 of the tank is arranged in the tank body. The heat from the side wall 1 of the aluminum electrolytic cell can be tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com