Method for preparing ultrafine drug particles in process of improving supercritical anti-solvent by nonsolvent method

A supercritical anti-solvent, non-solvent technology, applied in solution crystallization and other directions, can solve the problems of drugs that cannot fully exert their curative effect, difficult to absorb, and intense preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

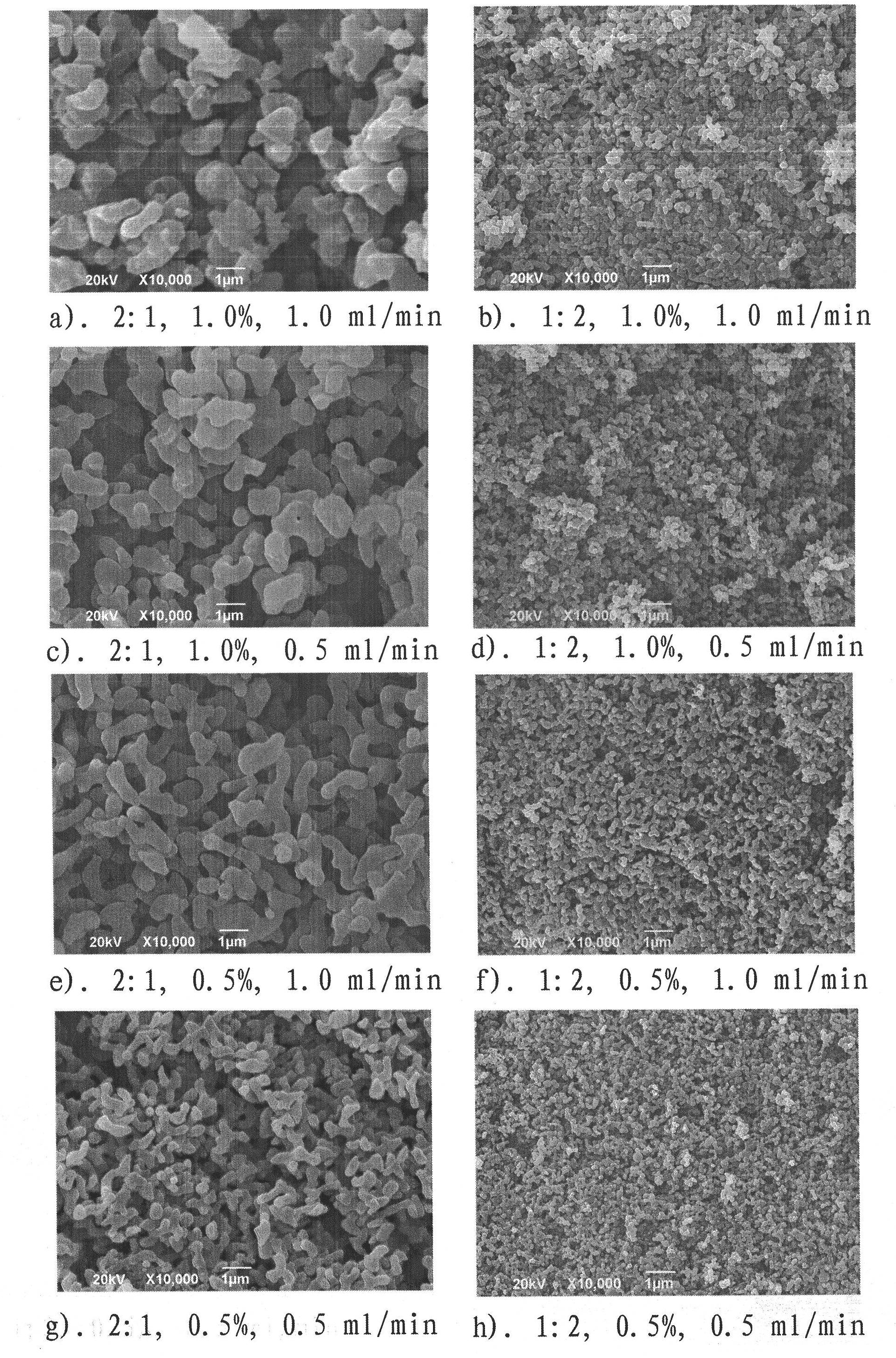

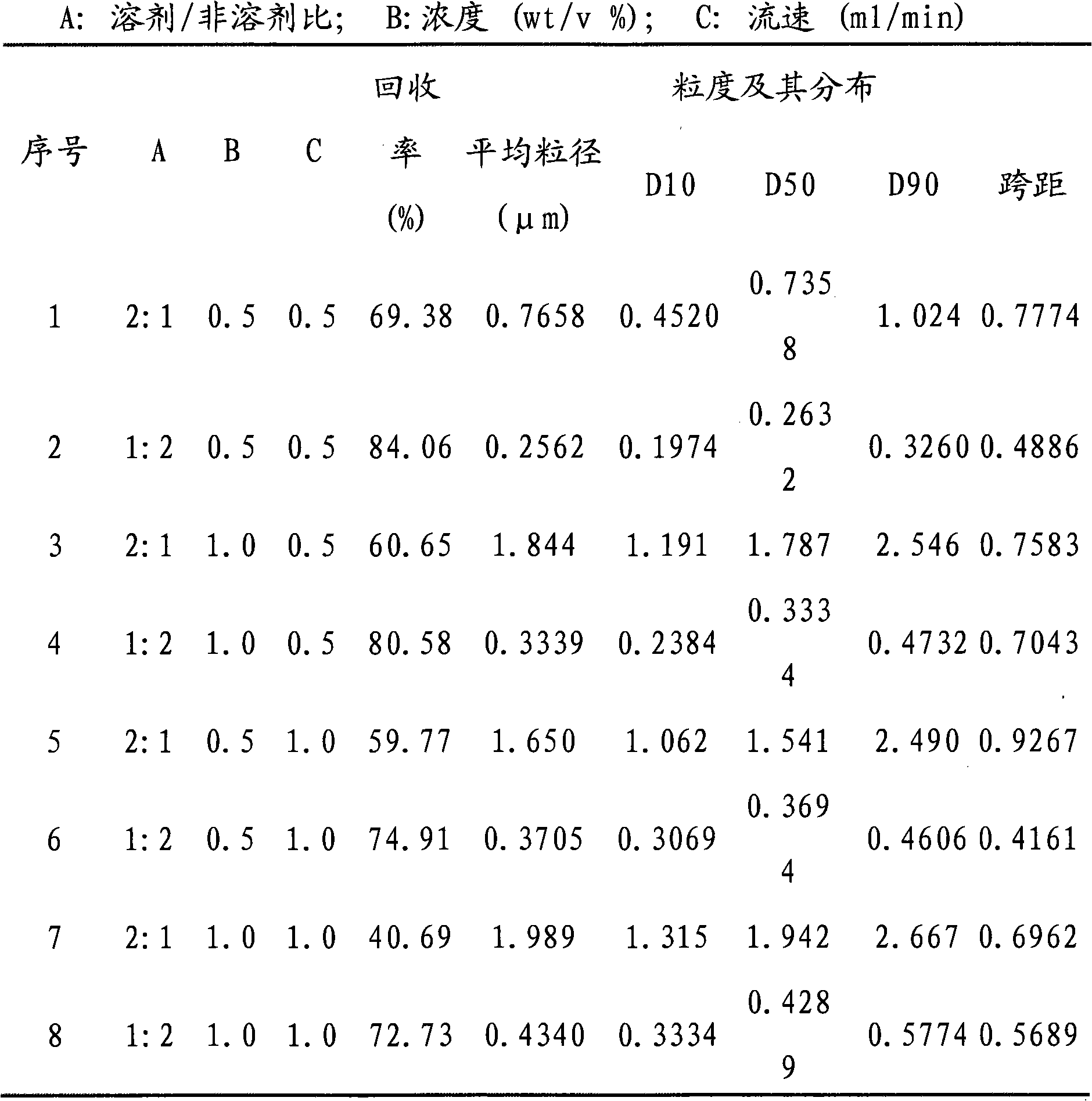

[0021] A full factorial experimental design was used to investigate the influence of factors such as solvent / non-solvent ratio, concentration and flow rate on the miniaturization of puerarin particles by supercritical carbon dioxide anti-solvent method. Such as figure 1 a experimental condition a).2:1, 1.0%, the implementation process of 1.0ml / min is as follows: the puerarin of 300mg is dissolved in the dehydrated alcohol of 20ml, then adds the non-solvent-dichloromethane of 10ml, obtains solvent / The non-solvent ratio is 2:1, and the concentration is 1.0% puerarin solution. After the carbon dioxide in the steel cylinder is liquefied by the refrigeration system, it is pressurized by the high-pressure plunger pump, and then pumped into the autoclave after the temperature is raised by the constant temperature water bath in the pipeline. The air release valve releases air at a certain rate, and adjusts the temperature of the external drying oven and pipeline water bath of the au...

Embodiment 2

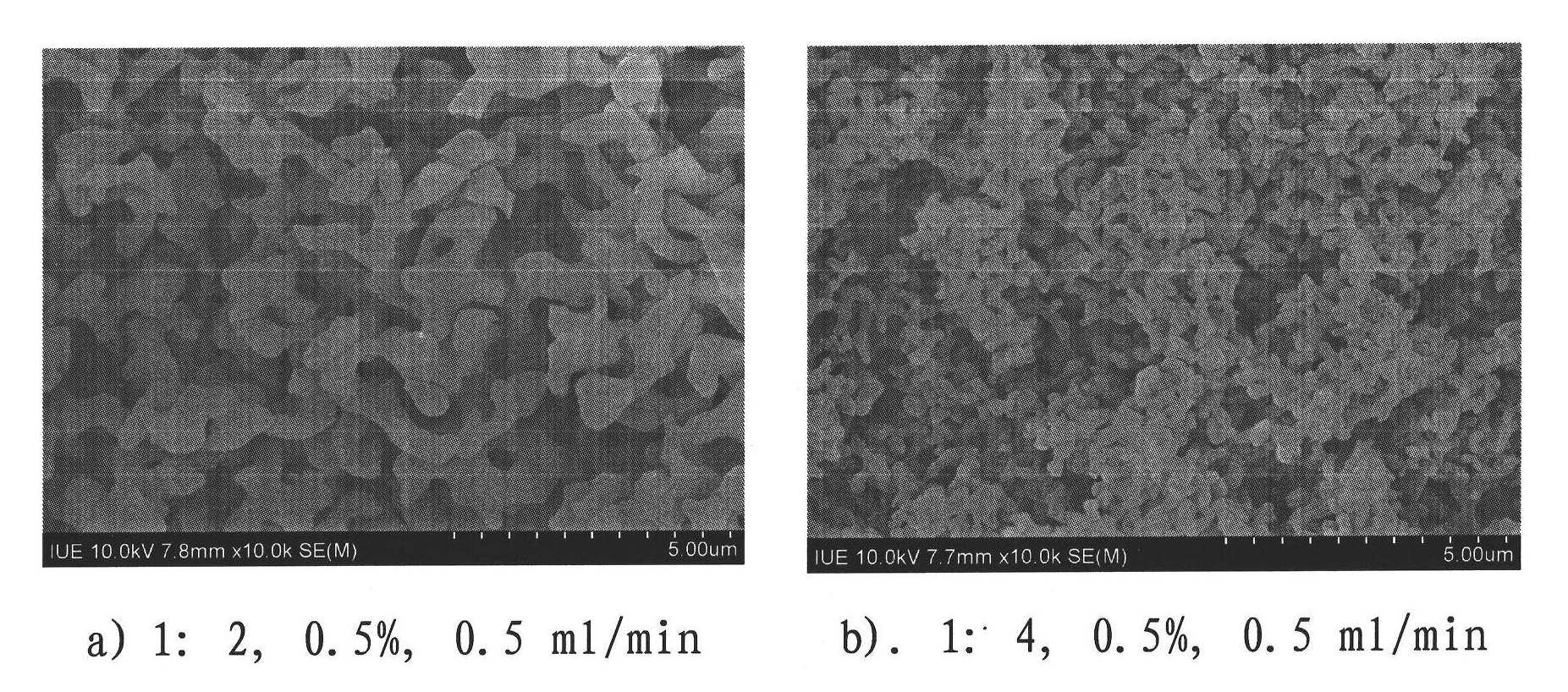

[0026] Dissolve methotrexate in dimethyl sulfoxide, and then add non-solvent acetone to obtain dimethyl sulfoxide / acetone ratios of 1:2 and 1:4, and a concentration of 0.5% methotrexate solution, with a flow rate of 0.5 ml / min is processed with the supercritical carbon dioxide anti-solvent process parameters in Example 1. The morphology of the obtained methotrexate ultrafine particles is as follows: figure 2 As shown, the average particle diameters are 1243nm and 446nm, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com