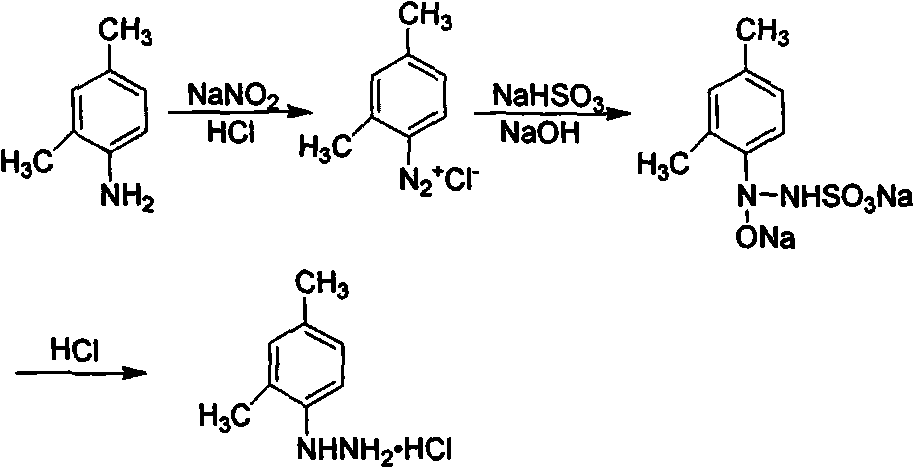

Method for synthesizing 2,4-dimethyl phenylhydrazine hydrochloride

A technology of dimethylphenylhydrazine and a synthesis method is applied in the synthesis process conditions of phenylhydrazine hydrochloride and the synthesis technology field of pharmaceutical intermediates, and can solve the problems of easy introduction of impurities, low yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific examples.

[0011] Literature reference example:

[0012] Synthetic Chemistry 2006, 14(3): 317-318 Example:

[0013] Dissolve 28.1g (50mmol) in 6mL glacial acetic acid in a beaker, heat to 70°C, quickly pour into hydrochloric acid [20mL (150mmol)] preheated to 30°C, stir for 25min, and quickly cool to 0°C with an ice-salt bath . Add sodium nitrite aqueous solution (3.6g sodium nitrite dissolved in 6.7mL water) dropwise within 6 minutes, add crushed ice at the same time to control the reaction temperature below 5°C, and react for 45 minutes to obtain the reaction solution A containing 3.

[0014] Dissolve 13 g of sodium bisulfite in 40 mL of water in a three-necked flask, adjust the pH to 6 with 40% aqueous sodium hydroxide solution, and cool to 5°C. The reaction solution A (below 10°C) was added dropwise within 20 minutes. At the same time, 40% sodium hydroxide solution was added dro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com