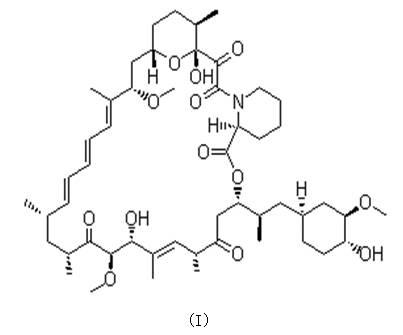

Method for separating and extracting Sirolimus from fermentation liquid

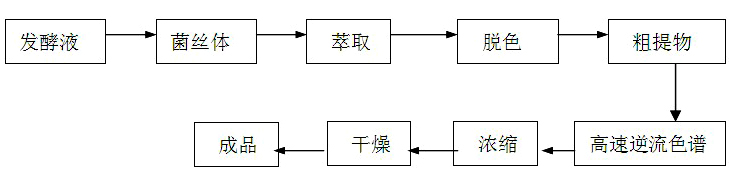

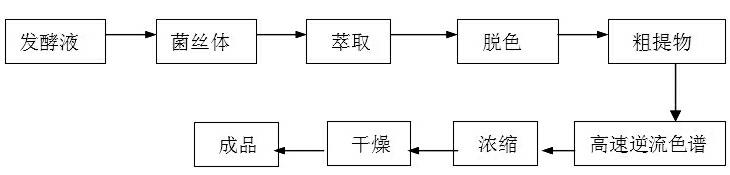

A technology for sirolimus and sirolimus bacteria, which is applied in the field of rapid separation and extraction of sirolimus, can solve the problems of high production cost, low fermentation level of strains, complicated production and extraction routes, etc. The effect of amplification, simple separation route and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1. Sirolimus fermented mycelium: take sirolimus fermented liquid and filter it with a frame filter, remove the fermentation supernatant, and obtain sirolimus mycelium.

[0018] 2. Extraction and decolorization: the mycelium was extracted 3 times with acetone solvent, the extract was further extracted 2 times with ethyl acetate, decolorized with activated carbon, concentrated under reduced pressure to obtain the crude extract of sirolimus.

[0019] 3. High-speed countercurrent chromatographic separation: the high-speed countercurrent chromatograph adopts TBE-300A produced by Shanghai Tongtian Biotechnology Co., Ltd. The separation method is to mix n-hexane-ethyl acetate-ethanol-water in the ratio (7:5:5:5, v / v) to form a two-phase solvent system, the upper phase is the stationary phase, and the lower phase is the mobile phase. 2 mL / min, rotation speed 800 r / min, detection wavelength 280 nm, about 100 mg of sirolimus crude extract was dissolved in 10 mL lower phase, injec...

Embodiment 2

[0022] 1. Sirolimus fermentation mycelia: take the sirolimus fermentation broth and separate it with a centrifuge at 4000 r / min, remove the fermentation supernatant, and obtain sirolimus mycelia.

[0023] 2. Extraction and decolorization: the mycelium was extracted 3 times with methanol solvent, the extract was further extracted 2 times with ethyl acetate, decolorized with activated carbon, concentrated under reduced pressure to obtain the crude extract of sirolimus.

[0024] 3. High-speed countercurrent chromatographic separation: the high-speed countercurrent chromatograph adopts TBE-300A produced by Shanghai Tongtian Biotechnology Co., Ltd. The separation method is to mix n-hexane-ethyl acetate-ethanol-water (6:5:5:5, v / v) into a two-phase solvent system, the upper phase is the stationary phase, and the lower phase is the mobile phase. mL / min, rotation speed 900 r / min, detection wavelength 280 nm, about 100 mg of sirolimus crude extract was dissolved in 10 mL of the lower p...

Embodiment 3

[0027] 1. Sirolimus fermented mycelium: take sirolimus fermented liquid and separate it by frame filtration, remove the fermentation supernatant to obtain sirolimus mycelium.

[0028] 2. Extraction and decolorization: the mycelium was extracted 3 times with ethanol solvent, the extract was further extracted 2 times with ethyl acetate, decolorized with activated carbon, concentrated under reduced pressure to obtain the crude extract of sirolimus.

[0029] 3. High-speed countercurrent chromatographic separation: the high-speed countercurrent chromatograph adopts TBE-300A produced by Shanghai Tongtian Biotechnology Co., Ltd. The separation method is to mix n-hexane-ethyl acetate-ethanol-water (5:5:5:5, v / v) into a two-phase solvent system, the upper phase is the stationary phase, and the lower phase is the mobile phase. mL / min, rotation speed 900 r / min, detection wavelength 280 nm, about 100 mg of sirolimus crude extract was dissolved in 10 mL of the lower phase, and the sample w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com