Method for preparing cyhalothrin molecular imprinting polymer microspheres

A technology of cyhalothrin and molecular imprinting, which is applied to the preparation of microspheres, microcapsule preparations, chemical instruments and methods, etc., can solve the problems of poor binding performance, irregular imprinted polymer particles, etc., and achieve easy operation and uniformity Good, easy to control the reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

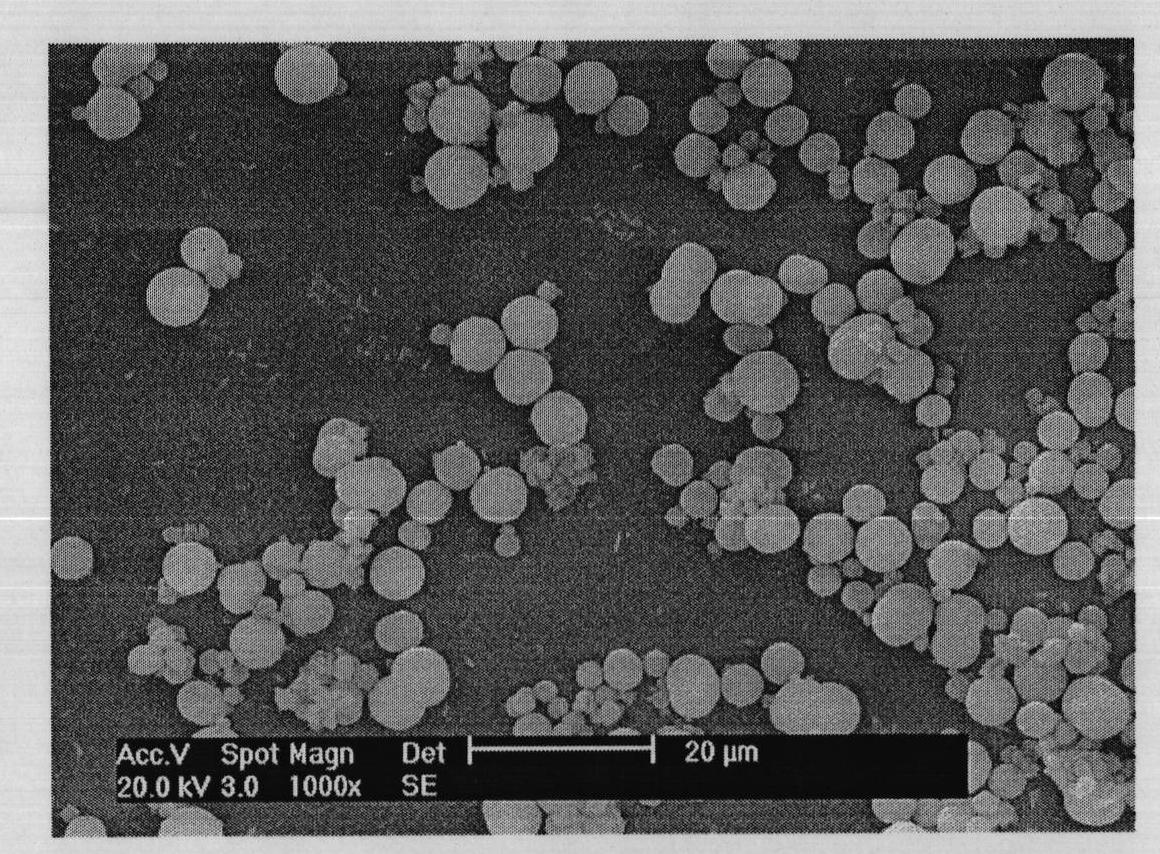

[0026] Example 1. A preparation method of cyhalothrin molecularly imprinted polymer microspheres, followed by the following steps:

[0027] Weigh 0.5mmol of cyhalothrin (as a template molecule) into a 150mL round bottom flask, dissolve it with 50mL of acetonitrile / toluene=3:1 (v / v), add 2mmol of acrylic acid (AA), mix well and shake Let stand for 1h at room temperature. Then add 10mmol of cross-linking agent DVB and 0.44mmol of initiator AIBN and mix well to obtain a mixed solution. First, the mixed solution was ultrasonically degassed (ultrasonic frequency 40KHz) for 10 minutes, and then placed on an ice water bath at 0-4°C, bubbling with nitrogen to remove oxygen for 10 minutes, strictly sealed and placed in a constant temperature oscillator for 24 hours (60°C, 50rpm). After the reaction was stopped, the polymer with white precipitate was collected by centrifugation (10000rpm, 15min), and the white precipitated polymer was re-dispersed in 50mL of methanol / acetic acid=9:1 (v / v)...

Embodiment 2

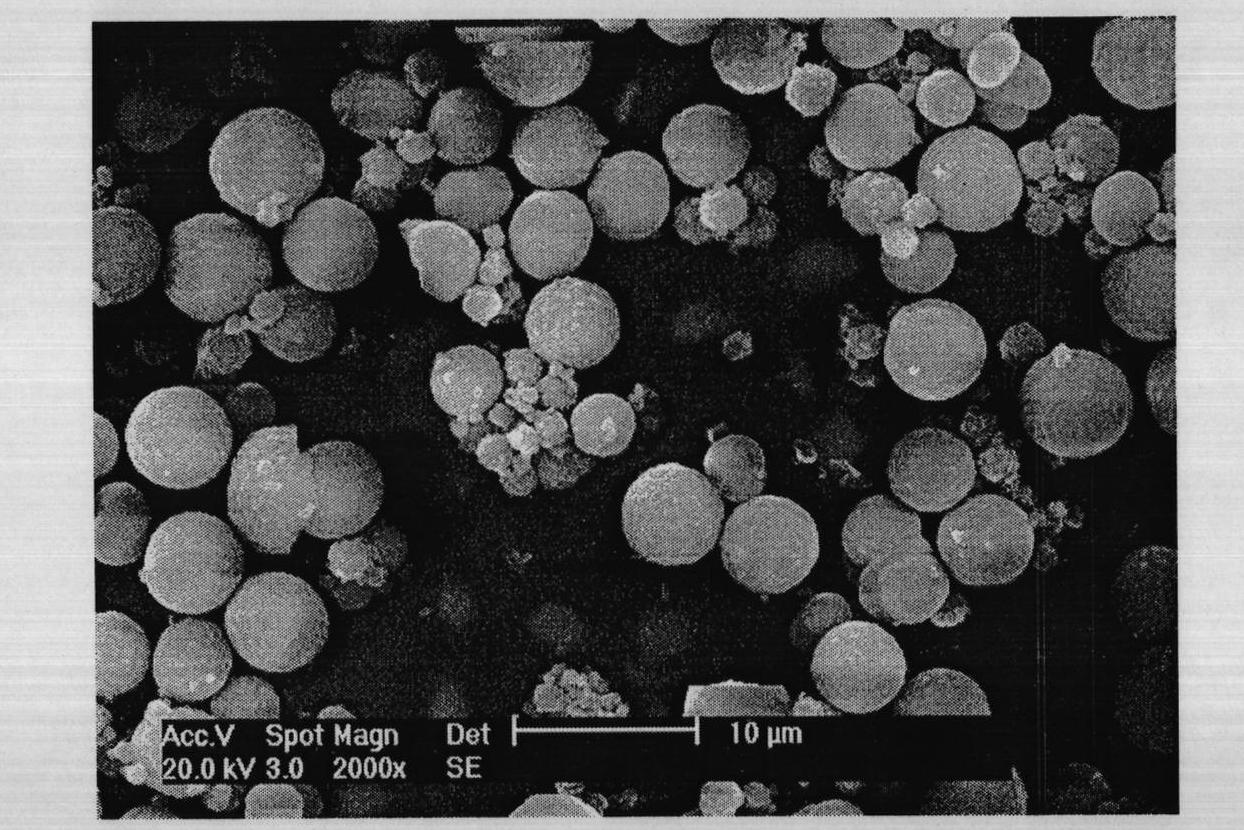

[0037] Example 2. A method for preparing cyhalothrin molecularly imprinted polymer microspheres, followed by the following steps:

[0038] Weigh 0.5mmol of cyfluthrin into a 150mL round bottom flask, dissolve it with 50mL of acetonitrile / toluene=3:1 (v / v), add 2mmol of 2-hydroxyethyl-methacrylate (HEMA), and mix After shaking evenly, let it stand for 1h. Then add 10mmol of cross-linking agent DVB and 0.44mmol of initiator AIBN and mix well to obtain a mixed solution. First, the mixed solution was ultrasonically degassed for 10 minutes, and then placed on an ice water bath at 0-4°C to bubbling nitrogen to remove oxygen for 10 minutes. After strict sealing, it was placed in a constant temperature oscillator to react for 24 hours (60°C, 50rpm). After the reaction was stopped, the polymer with white precipitate was collected by centrifugation (10000rpm, 15min), and the white precipitated polymer was re-dispersed in 50mL of methanol / acetic acid=9:1 (v / v) extract to obtain the polymer...

Embodiment 3

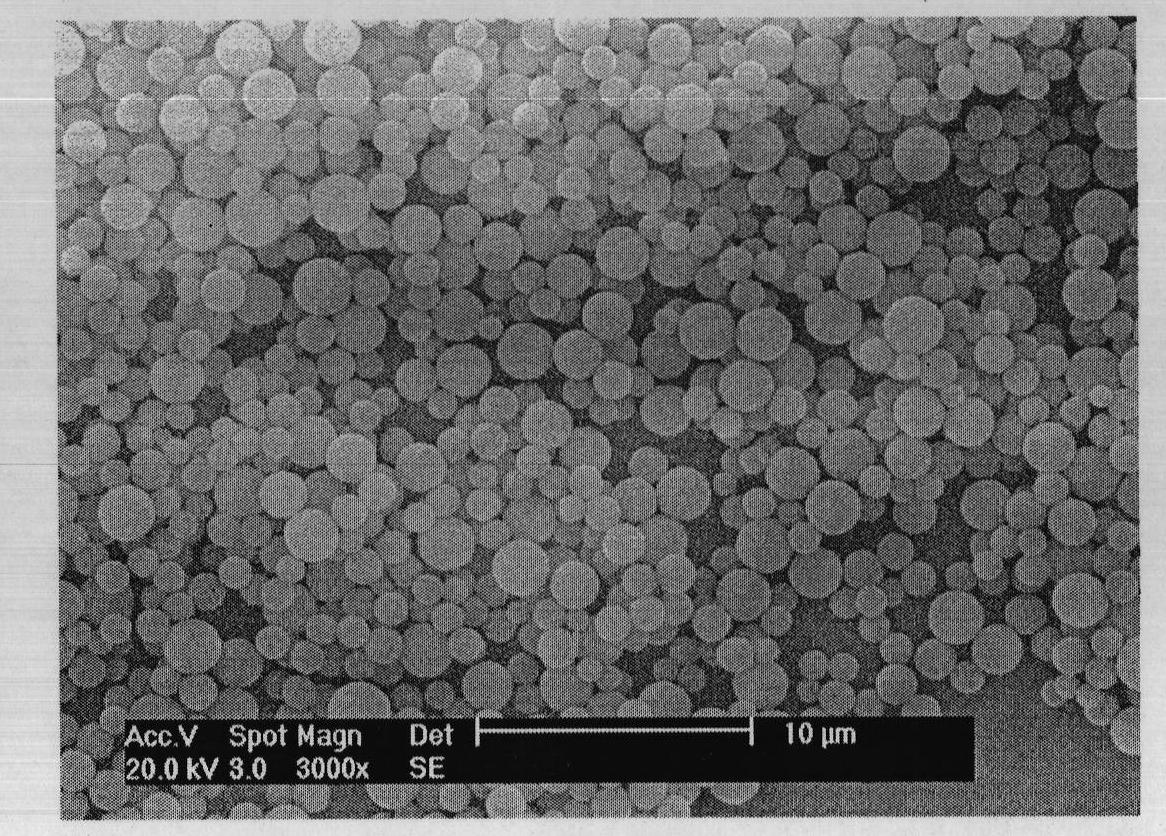

[0044] Embodiment 3. A method for preparing cyhalothrin molecularly imprinted polymer microspheres, followed by the following steps:

[0045] Weigh 0.5 mmol of cyhalothrin and place it in a 150 mL round bottom flask, dissolve it with 50 mL of acetonitrile / toluene = 3:1 (v / v), add 2 mmol of methacrylic acid (MAA), mix and shake, and then stand for 1 hour. Then add 10mmol of crosslinking agent DVB and 0.44mmol of initiator AIBN and mix well to obtain a mixed solution. First, the mixed solution was ultrasonically degassed for 10 minutes, and then placed on an ice water bath at 0-4°C to bubbling with nitrogen to remove oxygen for 10 minutes. After strict sealing, it was placed in a constant temperature oscillator for 24 hours (60°C, 50rpm). After the reaction was stopped, the polymer with white precipitate was collected by centrifugation (10000rpm, 15min), and the white precipitated polymer was re-dispersed in 50mL of methanol / acetic acid=9:1 (v / v) extract to obtain the polymer susp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com