Resorcinol formaldehyde resin base solid acid and preparation method and application thereof

A technology of resorcinol formaldehyde resin and resorcinol, which is applied in the preparation of carboxylic acid esters, dehydration of hydroxyl-containing compounds to prepare ethers, ether preparations, etc., can solve problems such as unsatisfactory, and achieve high thermal stability and acid value High, good catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: the preparation of resorcinol formaldehyde resin base solid acid

[0023] (1), the synthetic reaction of carbon-based solid acid:

[0024] Add 0.01mol of resorcinol, 0.001mol of isethionic acid, and 15g of water into the Erlenmeyer flask, stir and mix, and turn into a transparent solution, add 0.02mol of formaldehyde solution dropwise under stirring conditions, and immediately after the dropwise addition is complete After condensation in an oven at 85°C for 72 hours, a red solid was obtained, which was rotary evaporated to dryness to obtain a resin containing isethionic acid. Put the synthesized resin in a quartz tube, and carry out carbonization and condensation reaction at 250°C for 10 hours under nitrogen to obtain a black solid;

[0025] (2), washing, suction filtration and drying:

[0026] After the black solid prepared above is cooled to room temperature, add hot water above 80°C for washing, and filter until the filtrate is clear and acidic, and t...

Embodiment 2-4

[0028] The preparation method is the same as that of Example 1, except that the carbonization condensation reaction time is changed as shown in Table 1.

[0029] Table 1: Catalyst performance comparison under different carbonization condensation reaction times

[0030] Example

Embodiment 5-7

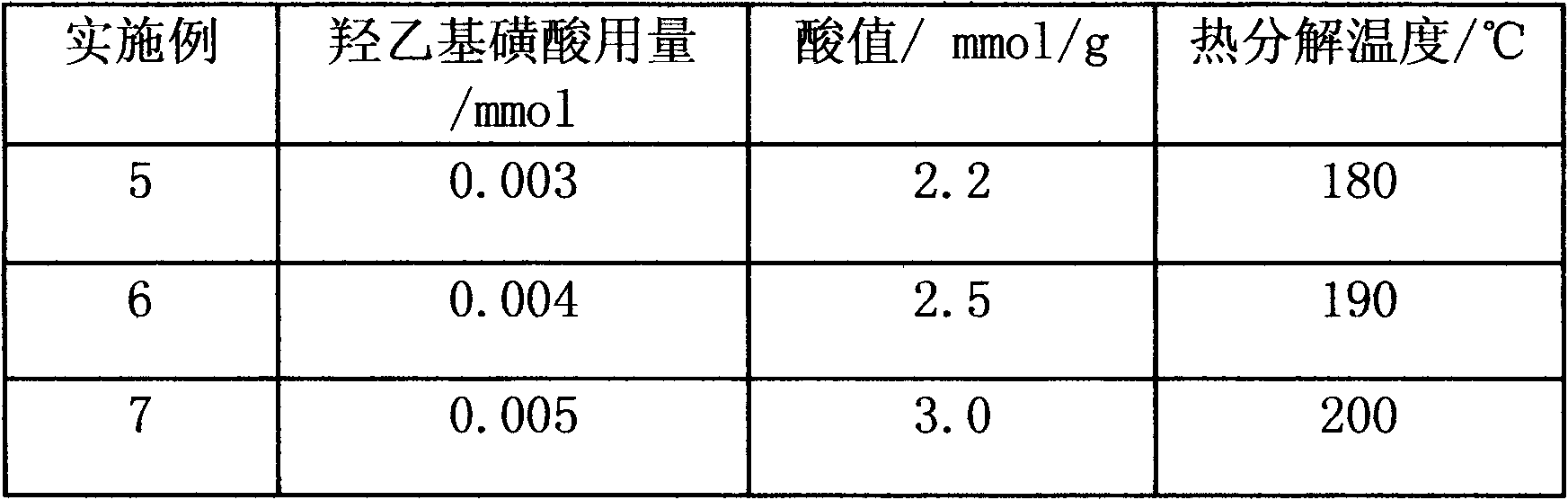

[0032] The preparation method is the same as that in Example 1, except that the amount of isethionic acid is changed as shown in Table 2.

[0033] Table 2: Catalyst performance comparison at different dosages of isethionic acid

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com