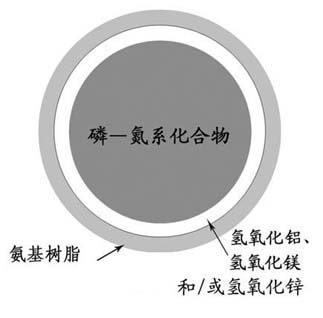

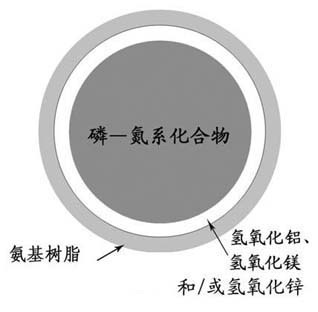

Amino resin-containing flame retardant and preparation method thereof

An amino resin and flame retardant technology, which is applied in the field of flame retardant, can solve the problems of increasing smoke hazard, unable to meet processing and use requirements, and increasing carbon monoxide concentration, and achieve the effect of reducing the concentration and toxicity of combustion smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A preparation method of a flame retardant containing amino resin, comprising the steps of:

[0041] 1) While stirring, add melamine pyrophosphate to water to form a suspension;

[0042] 2) Add aluminum sulfate aqueous solution to the suspension and keep it at 25°C for 120 minutes to obtain mixture A;

[0043] 3) Add ammonia solution to mixture A and keep at 25°C for 5 minutes to obtain mixture B;

[0044] 4) Add melamine formaldehyde resin to mixture B, adjust the pH to 5.0±0.5 with phosphoric acid, keep it at 25°C-30°C for 30 minutes, filter to make a paste flame retardant;

[0045] Among them, the number of moles of aluminum sulfate added per 100 grams of melamine pyrophosphate is 0.0064 moles; the molar ratio of aluminum sulfate to ammonia water is 1:0.001; the weight ratio of melamine pyrophosphate to amino resin is: 100:6.

Embodiment 2

[0047] A preparation method of a flame retardant containing amino resin, comprising the steps of:

[0048] 1) While stirring, add melamine phosphate to ethanol to make a suspension;

[0049] 2) Add magnesium chloride aqueous solution to the suspension and keep it at 95°C for 5 minutes to obtain mixture A;

[0050] 3) Add aqueous sodium hydroxide solution to mixture A and keep at 95°C for 5 minutes to obtain mixture B;

[0051] 4) Add melamine formaldehyde resin to mixture B, adjust pH to 5.0±0.5 with phosphoric acid, keep at 100°C for 30 minutes, and rotary evaporate to remove all solvents to make powdered flame retardant products;

[0052] Among them, the number of moles of magnesium chloride per 100 grams of melamine phosphate is 1.71 moles; the molar ratio of magnesium chloride to sodium hydroxide is 1:8.0; the weight ratio of melamine phosphate to amino resin is 100:8.

Embodiment 3

[0054] A preparation method of a flame retardant containing amino resin, comprising the steps of:

[0055] 1) While stirring, add aminourea phosphate to toluene to form a suspension;

[0056] 2) Add zinc sulfate aqueous solution to the suspension and keep it at 50°C for 60 minutes to obtain mixture A;

[0057] 3) Add ammonia solution to mixture A and keep at 50°C for 60 minutes to obtain mixture B;

[0058] 4) Add melamine-modified urea-formaldehyde resin to mixture B, adjust the pH to 5.0±0.5 with phosphoric acid, keep it at 95°C for 60 minutes, evaporate in vacuum to remove part of the solvent, and make a paste flame retardant of the present invention;

[0059] Among them, the molar number of zinc sulfate added to every 100 grams of aminourea phosphate is 0.032 moles; the molar ratio of zinc sulfate ammonia water is 1:0.06; the weight ratio of aminourea phosphate to amino resin is 100:4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com