Method for preparing sodium nitrite from nitric oxide waste gas through multistage oxidation absorption

A technology of nitrogen oxides and sodium nitrite, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problem of low NOx absorption efficiency, improve absorption efficiency, reduce NOx emissions, and achieve high investment ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

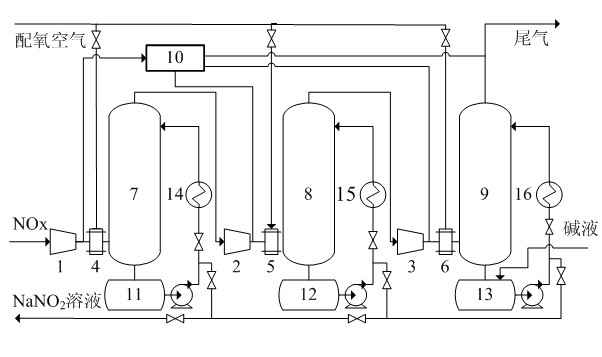

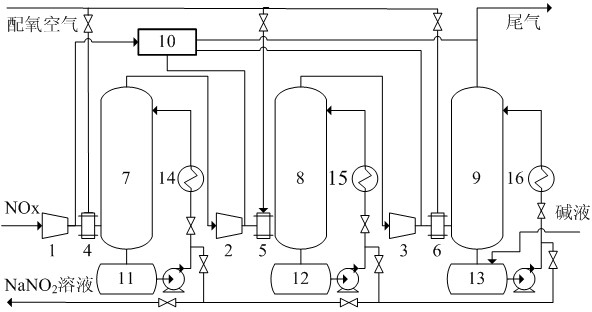

[0028] Three towers are used in series to absorb, the absorbent is NaOH solution, the concentration is 20%, the oxygen content in the oxygenated air is 40%, the intake air is NOx mixed gas, and the gas volume is 600Nm 3 / h, the pressure is 0.3MPa, NO 2 / NO is 0.2. Sodium nitrite solution is obtained through three-stage tower absorption operation, and all three towers use 350Y structured packing. The nitrogen oxide raw gas first enters the molecular sieve fixed bed for dehumidification and drying. After drying, the moisture content is 0.8ppm. In the oxidation box 4, the input amount of oxygen-mixed air is 125Nm 3 / h, the gas pressure at the outlet of the oxidation box is 0.5MPa, the packing height of the absorption tower 7 is 4m, the operating pressure is 0.6MPa, the absorption temperature is 40°C, and the spray density of NaOH liquid is 8.6m 3 / m 2 .h, condensation area is 20m 2 The gas at the top of the absorption tower 7 enters the molecular sieve fixed bed for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com