Microporous and mesoporous carbon xerogel having a characteristic mesopore size and precursors thereof and a process for producing these and their use

A technology of dry gel and wet gel, which is applied in the field of preparation of sol-gel method, and can solve the problem of not finding the characteristic repeating parameters of carbon aerogel and xerogel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] In a beaker, mix 3.66g phenol with 6.24g formaldehyde solution (37% aqueous formaldehyde solution stabilized with about 10% methanol) and 26.27g n-propanol (corresponding to the molar ratio F / P=2 of formaldehyde and phenol, phenol and The mass concentration of the formaldehyde reactant in the total solution (M=15%) is mixed. The solution was stirred on a magnetic stirrer until the phenol was completely dissolved. Subsequently, 3.83 g of 37% HCl were added (corresponding to a molar ratio of phenol to catalyst P / C=1). The solution was then added to a beaded edge bottle with a height of 10 cm (3 cm in diameter), and the beaded edge bottle was sealed airtight. The crimp bottle and samples were heated together in an oven at 85°C for 26h.

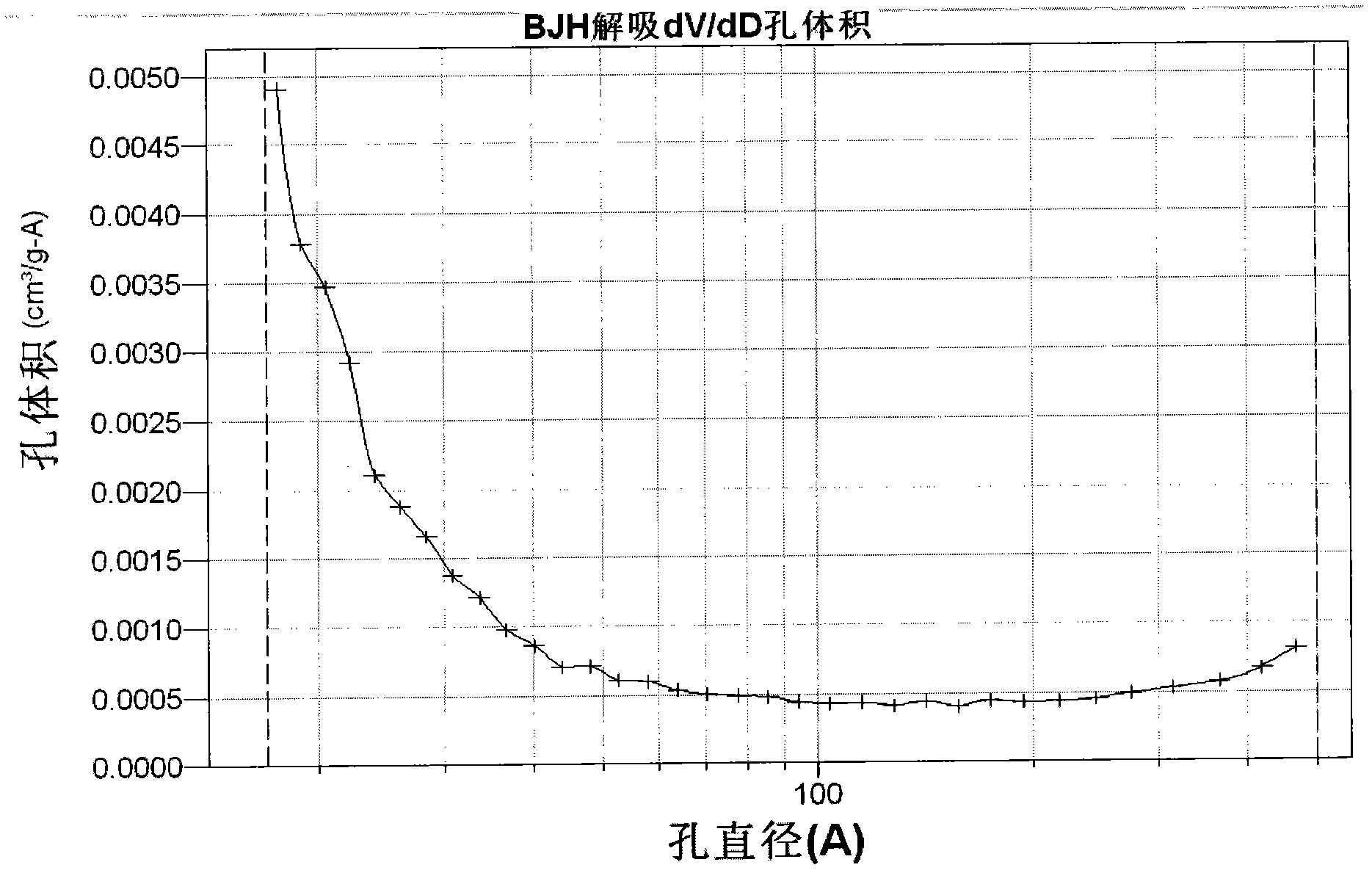

[0017] After 26 h, the monolithic organic wet gel was obtained, which was then convection dried in a drying oven at 65° C. for 70 h. Gained overall organic PF xerogel has 0.37g / cm 3 The macroscopic density (macroscopic density). Organ...

Embodiment 2

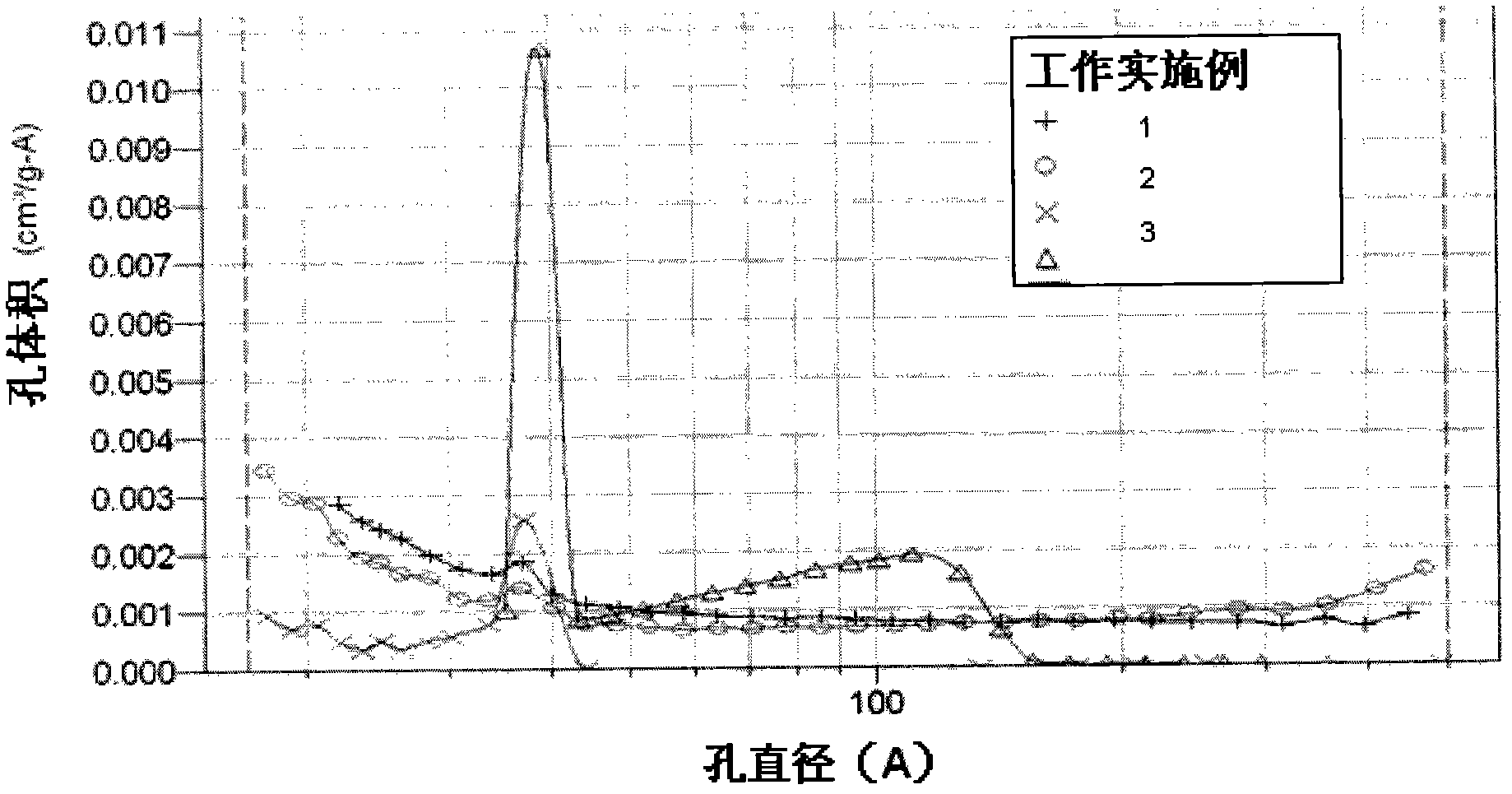

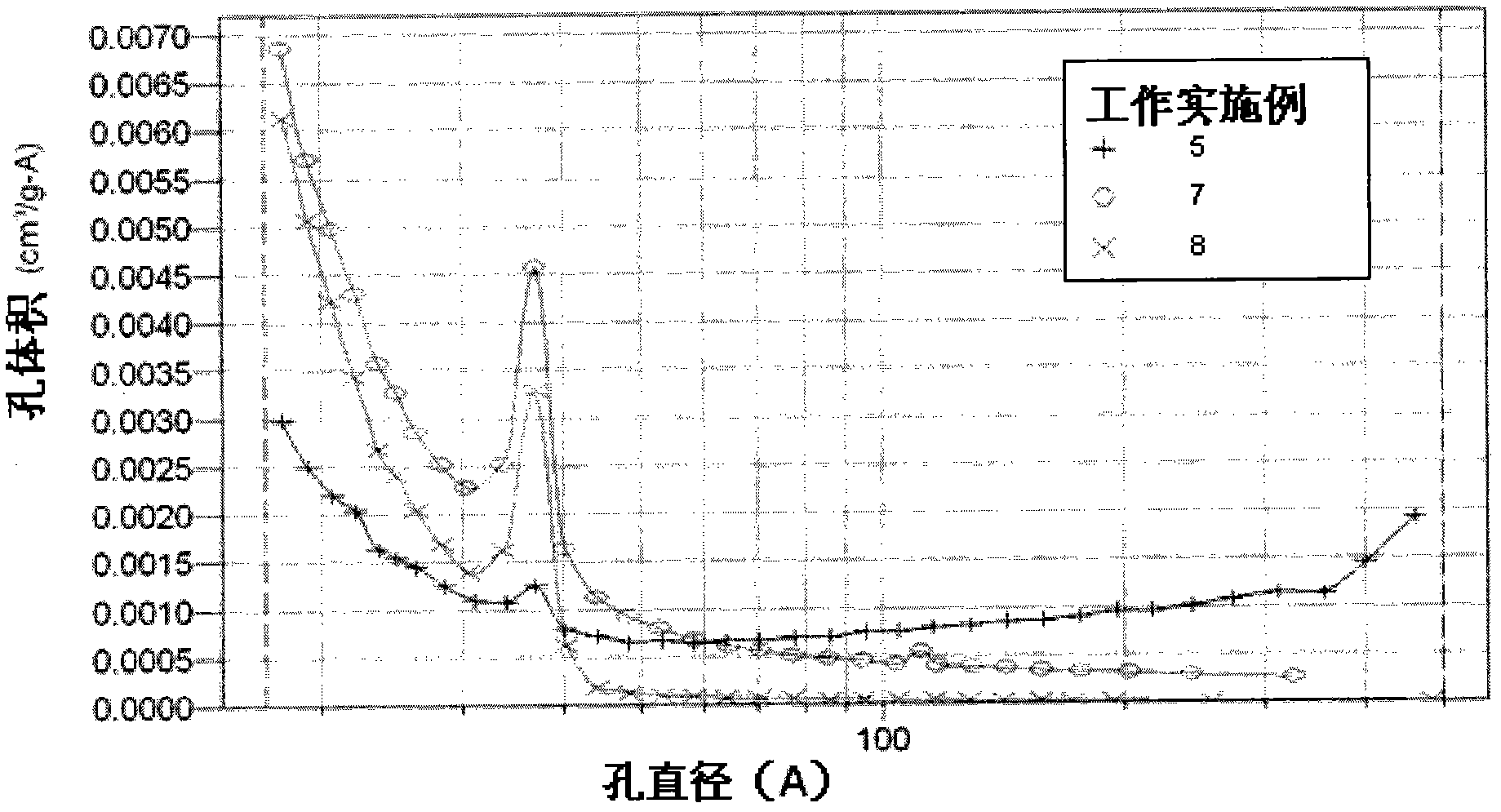

[0019] In a beaker, 6.11 g of phenol were mixed with 10.39 g of formaldehyde solution (37% aqueous formaldehyde solution stabilized with about 10% methanol) and 21.38 g of n-propanol (corresponding to F / P=2; M=25%). The solution was stirred on a magnetic stirrer until the phenol was completely dissolved. Subsequently, 2.18 g of 37% HCl (corresponding to P / C=2.95) were added. Then the solution was added into a crimp bottle with a height of 10 cm (3 cm in diameter), and the crimp bottle was sealed airtight. The crimp bottle and samples were heated together in an oven at 85°C for 24h.

[0020] After 24 h, the monolithic organic wet gel was obtained, which was then convection dried in a drying oven at 65° C. for 72 h. This gives a monolithic, ocher organic PF xerogel with 0.48 g / cm 3 macro density. From Figure 4 The specific surface area (BET surface area) calculated by the adsorption isotherm is 157m 2 / g, the external area is 130m 2 / g, mesopore volume is 0.38cm 3 / g. ...

Embodiment 3

[0022] In a beaker, 6.11 g of phenol were mixed with 3.89 g of paraformaldehyde and 27.87 g of n-propanol (corresponding to F / P=2; M=25). Stir the solution on a magnetic stirrer until the phenol and paraformaldehyde are completely dissolved. Subsequently, 2.14 g of 37% HCl (corresponding to P / C=3) were added. Then the solution was added into a crimp bottle with a height of 10 cm (3 cm in diameter), and the crimp bottle was sealed airtight. The crimp bottle and samples were heated together in an oven at 85°C for 24h.

[0023] After 24 h, the monolithic organic wet gel was obtained, which was then convection dried in a drying oven at 65° C. for 96 h. This obtains a 3 Macroscopic densities of monolithic organic PF xerogels. Organic PF xerogels were transformed into carbon xerogels by pyrolysis at 800 °C under argon atmosphere. The resulting carbon xerogel has a 1.14g / cm 3 The macro density, the specific surface area (BET) is 256m 2 / g, the micropore volume is 0.10cm 3 / g, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com