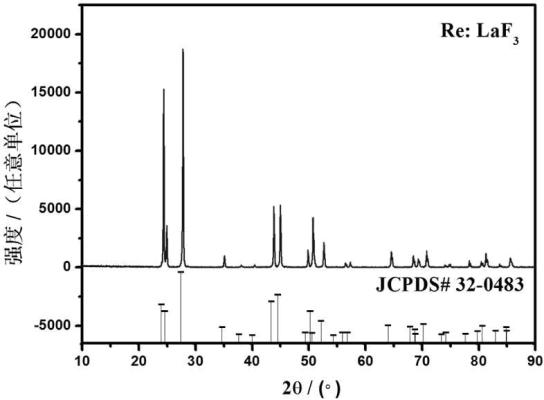

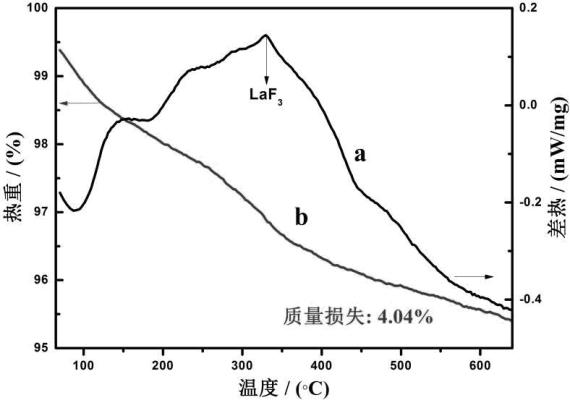

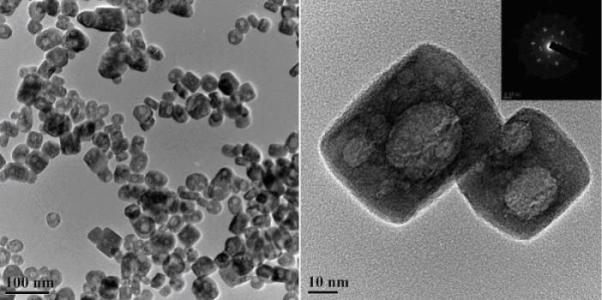

Method for preparing rare earth doped lanthanum fluoride luminous hollow nano powder by using multi-element solvothermal method

A technology of rare earth doping and hollow nano, which is applied in chemical instruments and methods, nanotechnology, nano optics, etc. It can solve the problems of few research and application reports and difficult preparation, and achieve uniform grain size distribution and good dispersion , the effect of high degree of crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Analytical balance weighs 6.19gLa 2 o 3 and 0.18gTb 4 o 7 , under strong magnetic stirring, carefully add an appropriate amount of concentrated nitric acid, keep warm at 60°C until completely dissolved, put the rare earth nitrate solution in an oven at 80°C, evaporate to dryness, add a mixture of deionized water, ethylene glycol, and oleic acid Solvent, formulated as La 3+ ,Tb 3+ Namely [Re 3+ ]=0.02mol / L solution. Under magnetic stirring, 240 ml (1.2 times excess) of ammonium fluoride solution with a concentration of 0.06 mol / L was added dropwise into the above solution, and the titration rate was controlled at 60 drops / min. After the titration is complete, add an appropriate amount of ammonia water dropwise to the prepared suspension to adjust the pH to 10. The solvothermal precursor suspension was quickly transferred to a polytetrafluoroethylene tank with a volume filling rate of 60%, and N was introduced into the polytetrafluoroethylene tank. 2 And quickly ...

Embodiment 2

[0019] Analytical balance weighs 6.19gLa 2 o 3 ,0.35gEu 2 o 3 , under strong magnetic stirring, carefully add an appropriate amount of concentrated nitric acid, keep warm at 60°C until completely dissolved, put the rare earth nitrate solution in an oven at 80°C, evaporate to dryness, add a mixture of deionized water, ethylene glycol, and oleic acid Solvent, formulated as La 3+ , Eu 3+ Namely [Re 3+ ]=0.02mol / L solution. Under magnetic stirring, 240 ml of ammonium fluoride solution with a concentration of 0.06 mol / L was added dropwise into the above solution, and the titration rate was controlled at 60 drops / min. After the titration is complete, add an appropriate amount of ammonia water dropwise to the prepared suspension to adjust the pH to 10. The solvothermal precursor suspension was quickly transferred to a polytetrafluoroethylene tank with a volume filling rate of 60%, and N was introduced into the polytetrafluoroethylene tank. 2 And quickly seal it and put it in...

Embodiment 3

[0021] Analytical balance weighs 5.86gLa 2 o 3 ,0.67gNd 2 o 3 , under strong magnetic stirring, carefully add to an appropriate amount of concentrated nitric acid, keep warm at 60°C until the oxide is completely dissolved, put the rare earth nitrate solution in an oven at 80°C and evaporate to dryness, then add deionized water, ethylene glycol, and oleic acid A mixed solvent, prepared as La 3+ ,Nd 3+ Namely [Re 3+ ]=0.02mol / L solution. Under magnetic stirring, 240 ml of ammonium fluoride solution with a concentration of 0.06 mol / L was added dropwise into the above solution, and the titration rate was controlled at 60 drops / min. After the titration is complete, add an appropriate amount of ammonia water dropwise to the prepared suspension to adjust the pH to 10. The solvothermal precursor suspension was quickly transferred to a 125ml polytetrafluoroethylene tank with a volume filling rate of 60%, and N was introduced into the polytetrafluoroethylene tank. 2 And quickly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com