Chip type oxygen sensor and preparation method thereof

An oxygen sensor and chip technology, applied in the field of chip oxygen sensor and its preparation, can solve the problems of short service life, low sensitivity of oxygen sensor, poor thermal shock resistance, etc., achieve long service life, improve sensitivity, and enhance adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

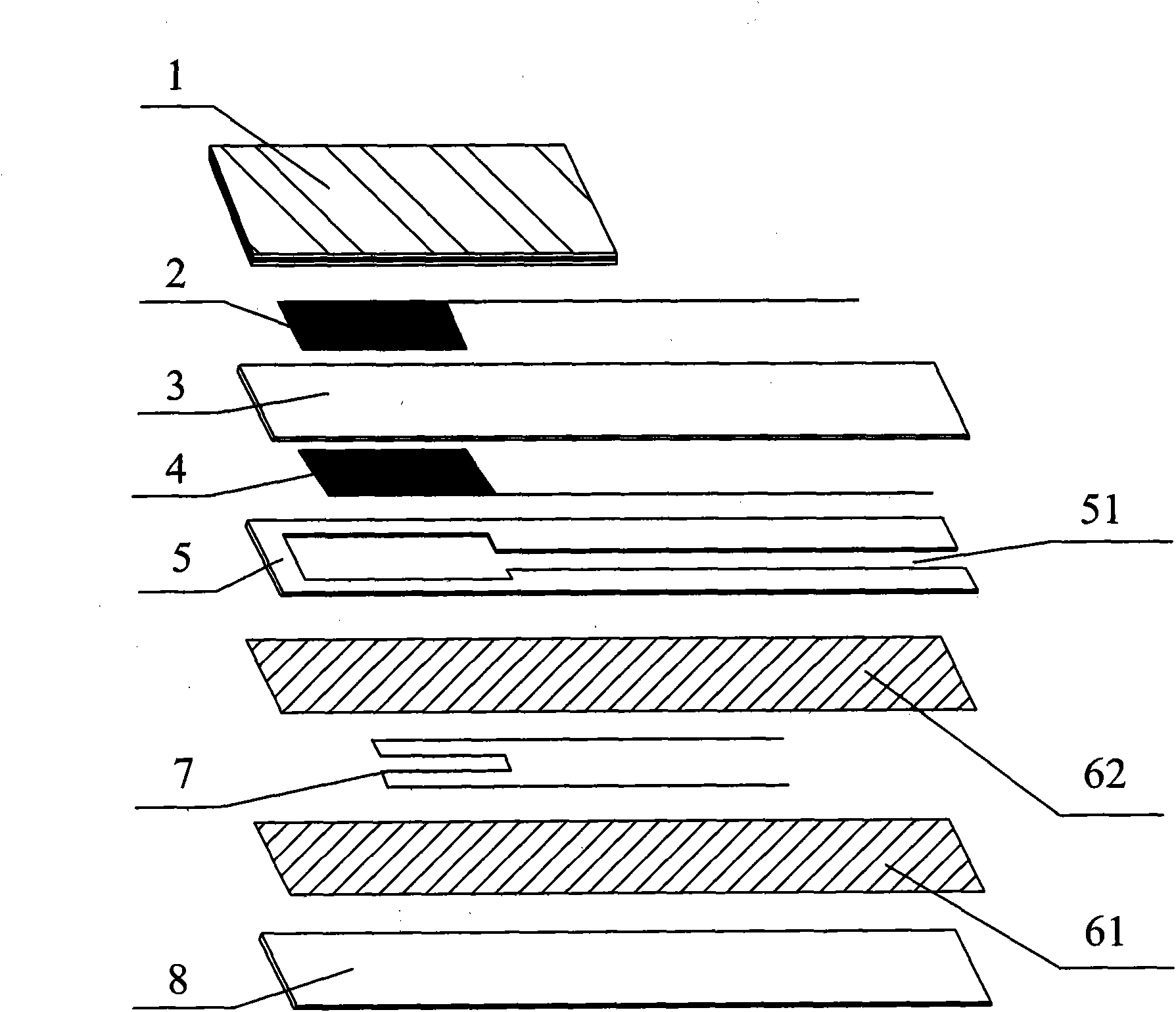

[0025] The present invention also provides a preparation method of a chip oxygen sensor, comprising the following steps:

[0026] 1) Coating insulating layer slurry, electrode slurry, and insulating layer slurry on the heater substrate, drying, forming an insulating layer on the heater substrate, and obtaining the first sheet; getting a reference gas substrate as second sheet;

[0027] 2) screen-print the transition layer slurry on the oxygen measuring electrolyte layer to form a transition layer; the transition layer slurry contains zirconia, magnesium aluminum spinel and the first pore-forming agent; screen-print the porous layer slurry to form a transition layer; A porous layer is formed on the layer; the porous layer slurry contains zirconia, magnesium aluminum spinel, noble metal and the second pore-forming agent; the third layer is obtained; take a zirconia casting sheet and laser drill holes to obtain a dense Layer, as the fourth layer;

[0028] 3) One side of the ins...

Embodiment 1

[0042] (1) The heater substrate, the reference gas substrate blank, and the zirconia electrolyte matrix are prepared by casting technology; the insulating layer, the heating electrode, and the insulating layer are successively coated on the heater substrate by a screen printing process. The heater substrate is used as the first layer; the reference gas substrate blank is laser cut out of the air channel to make the reference gas substrate as the second layer; the oxygen measuring electrolyte is made by printing the upper electrodes on both sides of the zirconia electrolyte substrate Floor.

[0043] (2) Raw material preparation:

[0044] Transition layer slurry: (a) powder material: 65 parts by weight of zirconia; 27 parts by weight of magnesium aluminum spinel; 5 parts by weight of activated carbon (particle size: 1.8-4 μm) as a pore forming agent; 3 parts by weight of sintering aid ( Wherein aluminum oxide 1 weight part, magnesium oxide 1 weight part, calcium oxide 1 weight ...

Embodiment 2

[0050] The same method as in Example 1 is used to prepare the chip oxygen sensor of this example, the difference is that in step (4), the area of the zirconia casting sheet is larger than that of the transition layer and the porous layer, and the porous layer is completely covered. Floor.

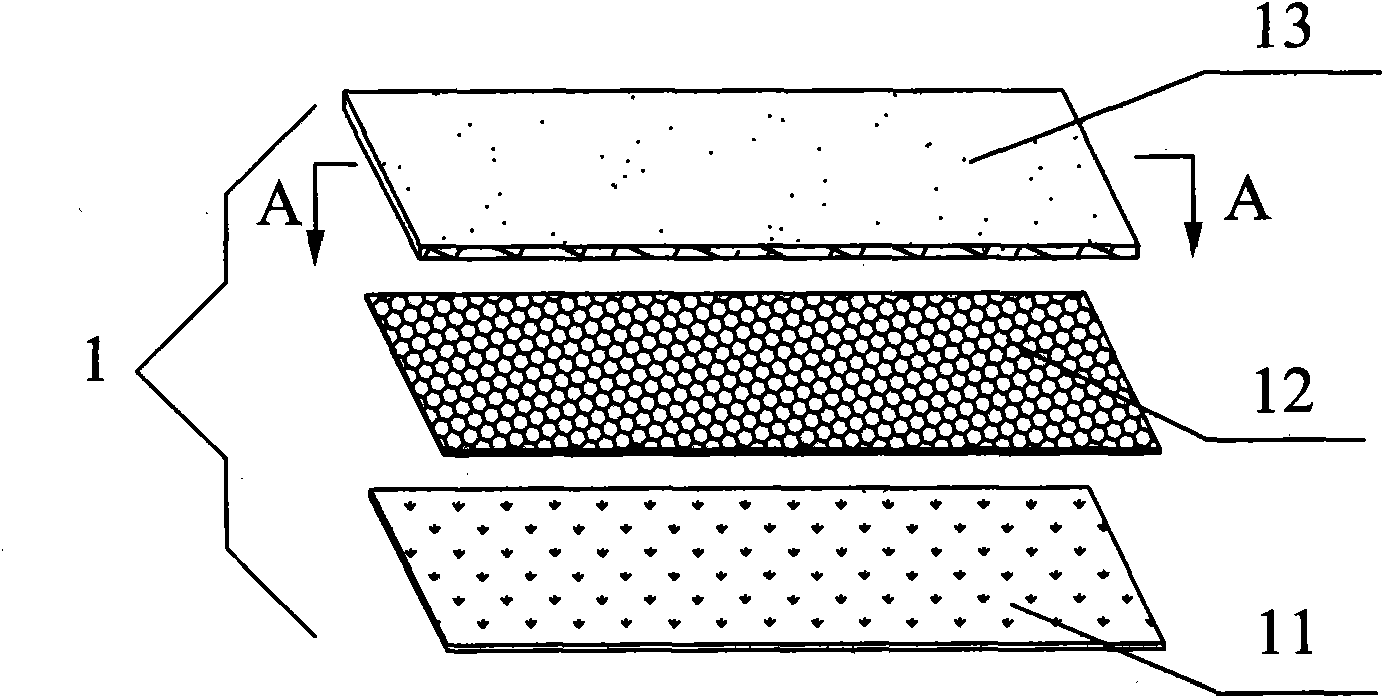

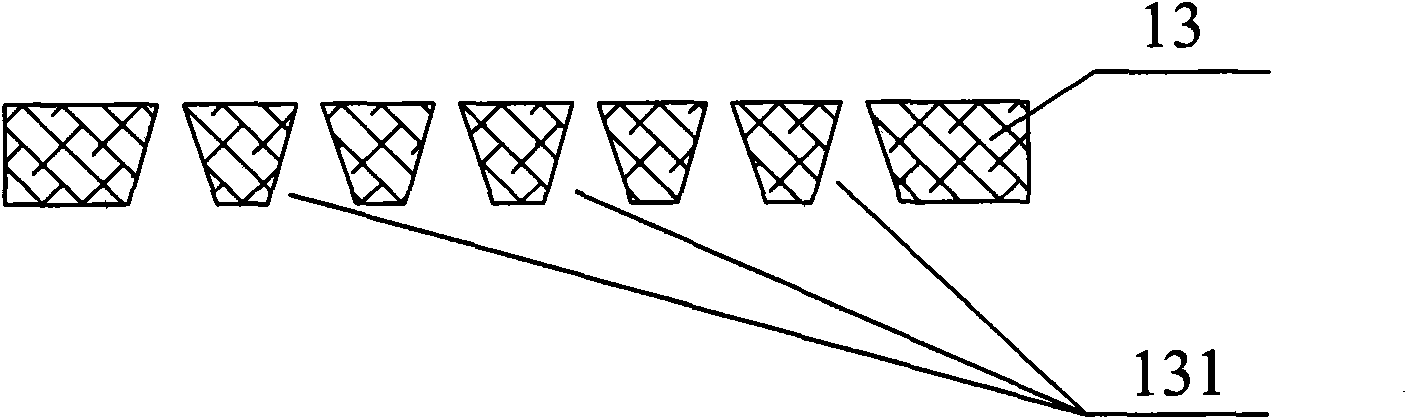

[0051] Through the above steps, the chip oxygen sensor of this embodiment is obtained, which has figure 1 The structure shown, in which the porous protective layer has Figure 4 The structure shown is denoted as A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com