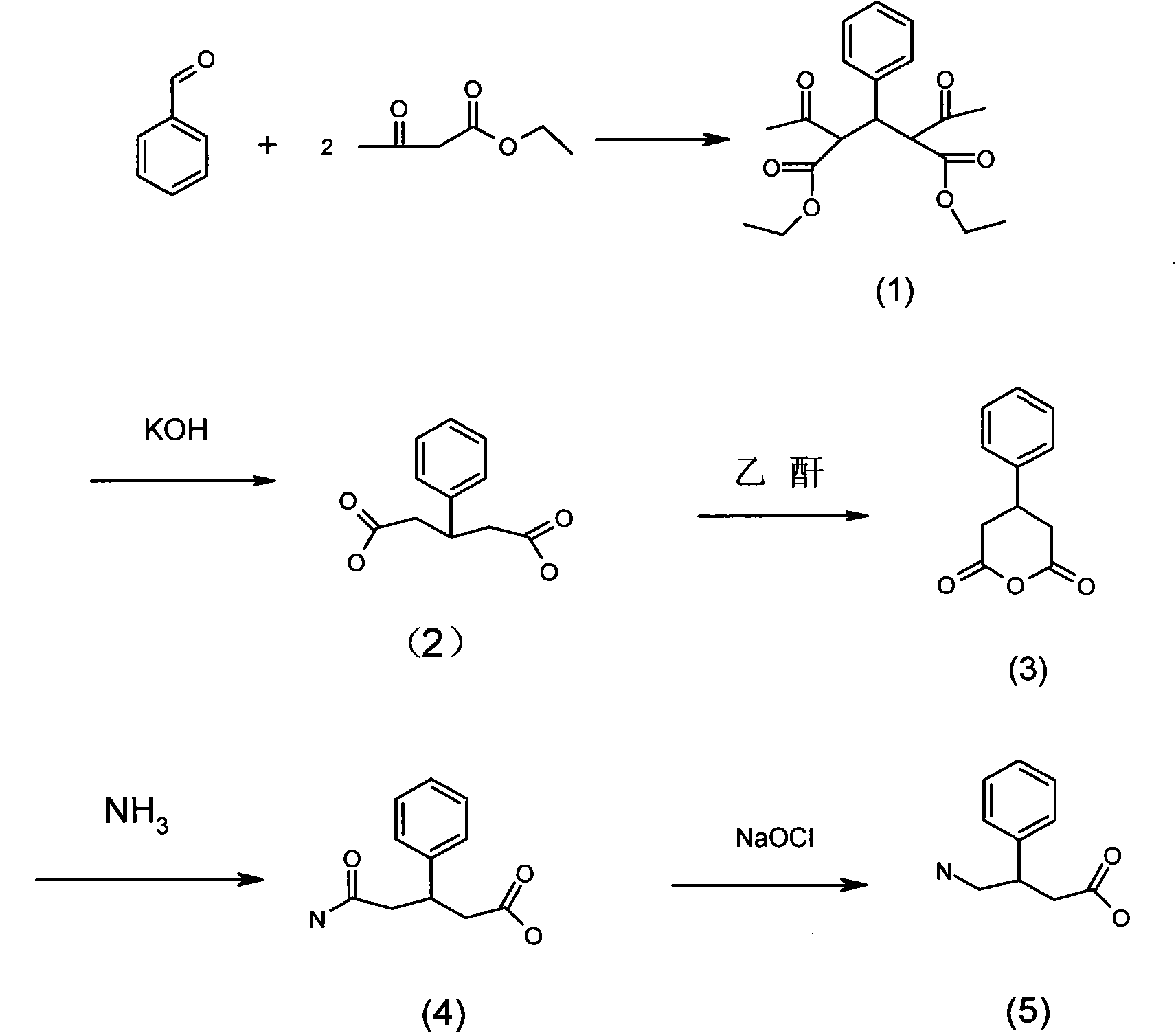

Preparation method for 4-amino-3-phenylbutyric acid

A technology of phenylbutyric acid and phenylvaleric acid, which is applied in the preparation of organic compounds, chemical instruments and methods, and cyanide reaction preparation, etc., can solve problems such as unsafe hidden dangers, risks in factory production, and complicated operations. , to achieve the effect of simple operation, mild reaction conditions and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred implementation of the present invention will be described in detail below according to the examples.

[0028] 1, 2, the synthesis of 4-diacetyl-3-phenyl-pentanedionate diethyl ester (1)

[0029] Add 26.5 g of benzaldehyde, 65 g of ethyl acetoacetate, and 106 g of 95% ethanol into the reaction flask, add 4 g of piperidine under stirring, react for 5.5 hours, stop stirring, and stand still. From the beginning of adding piperidine to the end of the reaction, a total of 36 hours, the temperature was controlled at less than 40°C. Cool to room temperature, suction filter after 2 hours, wash the filter cake with a small amount of ethanol, recover the mother liquor and use it mechanically. The filter cake was dried to obtain 68 g of the needle-like crystal product 2,4-diacetyl-3-phenyl-pentanedionate (1), with a yield of 78.2%, Mp: 149-153° C., document (jour. Indianchem.soc., Vol.40, No.10, 1983) melting point: 150°C.

[0030] 2. Synthesis of 3-phenylglutaric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com