Heat insulation and water prevention integration building roof and construction method thereof

A construction method and construction technology, applied to building roofs, roofs, buildings, etc., can solve the problems of poor fire performance, fire prevention, durability and compressive strength, etc., to prevent damage, avoid bulges and internal condensation, The effect of improving thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

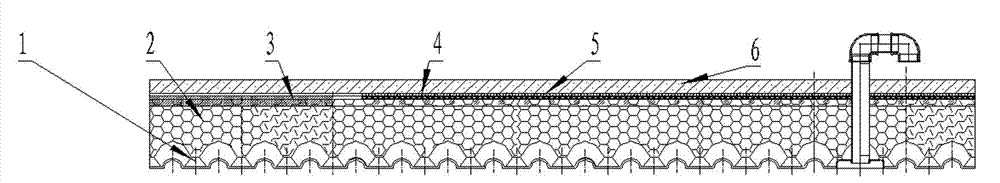

[0030] Embodiment 1: The construction method of flat roof. Firstly, thermal insulation tiles are laid sequentially on the structural surface of the flat roof, and polystyrene foam concrete is pumped and poured on the tiles; that is, one thermal insulation tile is placed on the lap joint, and one is poured at any time, and at the same time, the thickness and peace are in accordance with the design. Level waterproofing and slope finding require scraping. That is to say, the cast-in-place polystyrene foam concrete layer also has the function of waterproofing and slope finding on the flat surface, and it is operated in this way until the entire working surface is completed. When the cast-in-place polyphenylene foam concrete layer is in a semi-dry state, start to spray the polymer emulsion, the strength can be improved, and then scrape the waterproof coating, and bond the polymer non-woven waterproof membrane, the polymer non-woven After the woven fabric waterproofing membrane is ...

Embodiment 2

[0031] Embodiment 2: The construction method of slope roof. First of all, put the thermal insulation tiles sequentially on the structural surface of the slope roof, and use a nail gun to nail the thermal insulation tiles on the structural surface. The tail of the nail must be 10mm higher than the thermal insulation tile, so that the tail of the nail can hold Wrapped in the cast-in-place polystyrene foam concrete layer to prevent the waterproof and thermal insulation layer from sliding on the structural surface. While placing, lapping, and nailing the insulation tiles, the polystyrene foam concrete can be pumped and poured, and scraped according to the designed thickness until the entire working surface is completed. When the cast-in-place polyphenylene foam concrete layer is in a semi-dry state, start to spray the polymer emulsion, and after the strength can be reached, apply waterproof coating and bond the polymer coil. If the polymer membrane is resistant to solar radiation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com