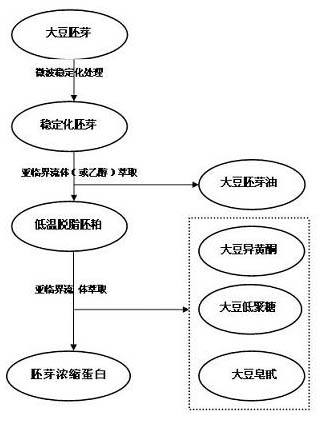

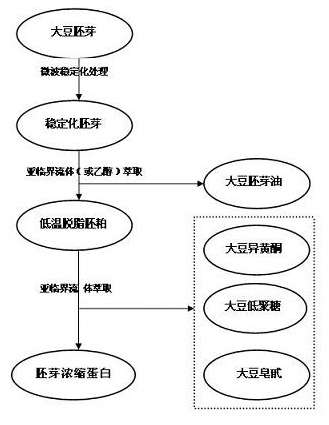

Method for producing germ oil, oligosaccharides and protein concentrate by using soybean germs

A soybean oligosaccharide and soybean germ technology, which is applied in the directions of oligosaccharides, chemical instruments and methods, protein food ingredients, etc., can solve the problem of unspecified quality status of defatted soybean germ meal, high production cost of soybean germ protein, and soybean germ protein. Problems such as poor quality of concentrated protein, to save equipment investment, low production cost, and prevent rancidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The fresh soybean germ just separated from the production line of the oil mill is conveyed by a conveyor and enters a microwave stabilization device for enzyme inactivation. The process conditions are: microwave power 0.15kW / kg germ, microwave action time 5min. The soybean germ stabilized by microwave is rolled into 0.4mm flakes with a flaking machine.

[0050] Take 1000 kg of the above-mentioned soybean germ, use liquefied butane as lysozyme, and carry out countercurrent extraction for 3 times, the extraction time is 45 minutes, the mass ratio of solid to liquid is 1:3, and the extraction temperature is 25°C. The extracted mixed oil and wet meal enter the evaporation system and are desolvated under reduced pressure. Obtain soybean germ crude oil 95kg, defatted soybean germ 902kg. The butane gas evaporated from the mixed oil and wet meal is then compressed by the compressor, condensed and liquefied, and then recycled.

[0051] Get 50 kg of soybean germ crude oil, firs...

Embodiment 2

[0056] The fresh soybean germ just separated from the low-temperature soybean protein production enterprise is transported by the conveyor and enters the steam stabilization device for enzyme inactivation. The technological conditions are as follows: 500kg of germ is fed at one time, the steam pressure is 5kg, and the processing time is 8min. Then, the steam-stabilized soybean germ was rolled into 0.5mm flakes by a flaking machine.

[0057] Take 1000 kg of the above-mentioned soybean germ, use liquefied butane as the lysozyme, and conduct countercurrent extraction twice, the extraction time is 30 minutes, the ratio of solid to liquid is 1:3, and the extraction temperature is 25°C. The extracted mixed oil and wet meal enter the evaporation system and are desolvated under reduced pressure. Obtain soybean germ crude oil 86kg, defatted soybean germ 901kg. The solvent gas evaporated from the mixed oil and wet meal is compressed by the compressor, condensed and liquefied, and then...

Embodiment 3

[0063] The fresh soybean germ just separated from the production line of the oil mill is conveyed by a conveyor and enters a microwave stabilization device for enzyme inactivation. The process conditions are: microwave power 0.15kW / kg germ, microwave action time 5min. The soybean germ stabilized by microwave is rolled into 0.4mm flakes with a flaking machine.

[0064]Take 1000kg of the above-mentioned soybean germ, use liquefied LPG as the lysozyme, and carry out 2 times of countercurrent extraction, the extraction time is 60 minutes, the ratio of solid to liquid is 1:4, and the extraction temperature is 25°C. The extracted mixed oil and wet meal enter the evaporation system and are desolvated under reduced pressure. The solvent gas evaporated from the mixed oil and wet meal is compressed by the compressor, condensed and liquefied, and then recycled. Obtain soybean germ crude oil 89kg, defatted soybean germ 900kg. Using conventional winterization, alkali refining and decolor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com