Adsorption resin with large specific surface area and large pore volume for removing volatile organic pollutants

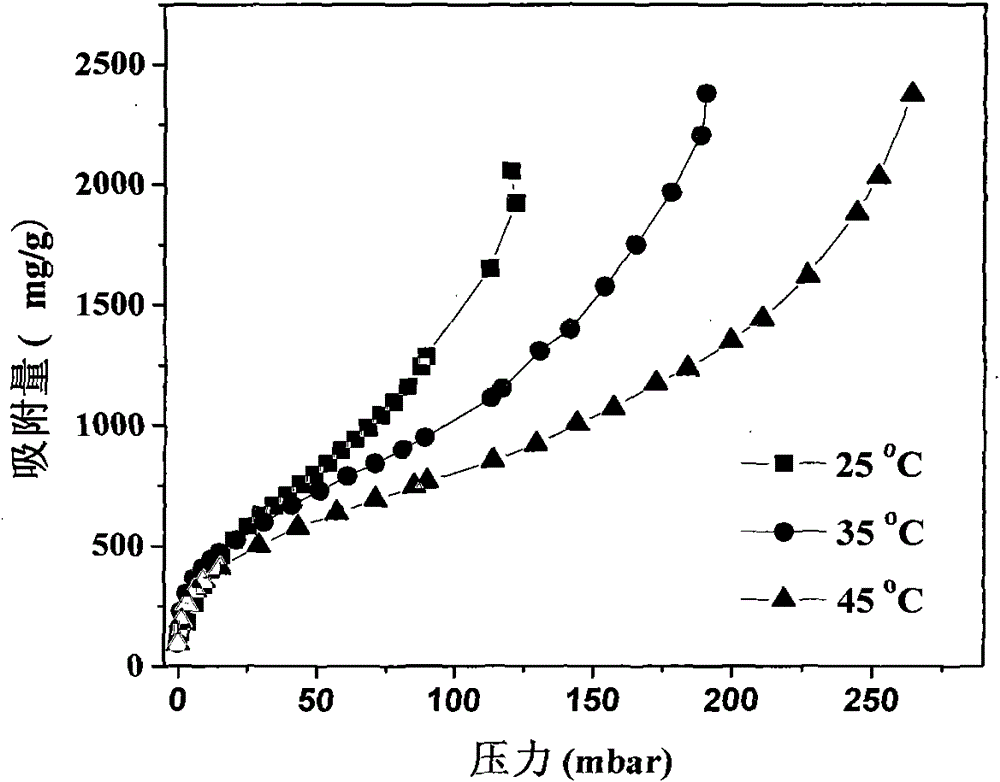

A large specific surface area, volatile organic technology, applied in inorganic chemistry, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve problems such as difficult adsorption and desorption processes, large mass transfer resistance, and high specific surface area , to achieve strong hydrophobicity and organophilicity, low mass transfer resistance, and increase the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

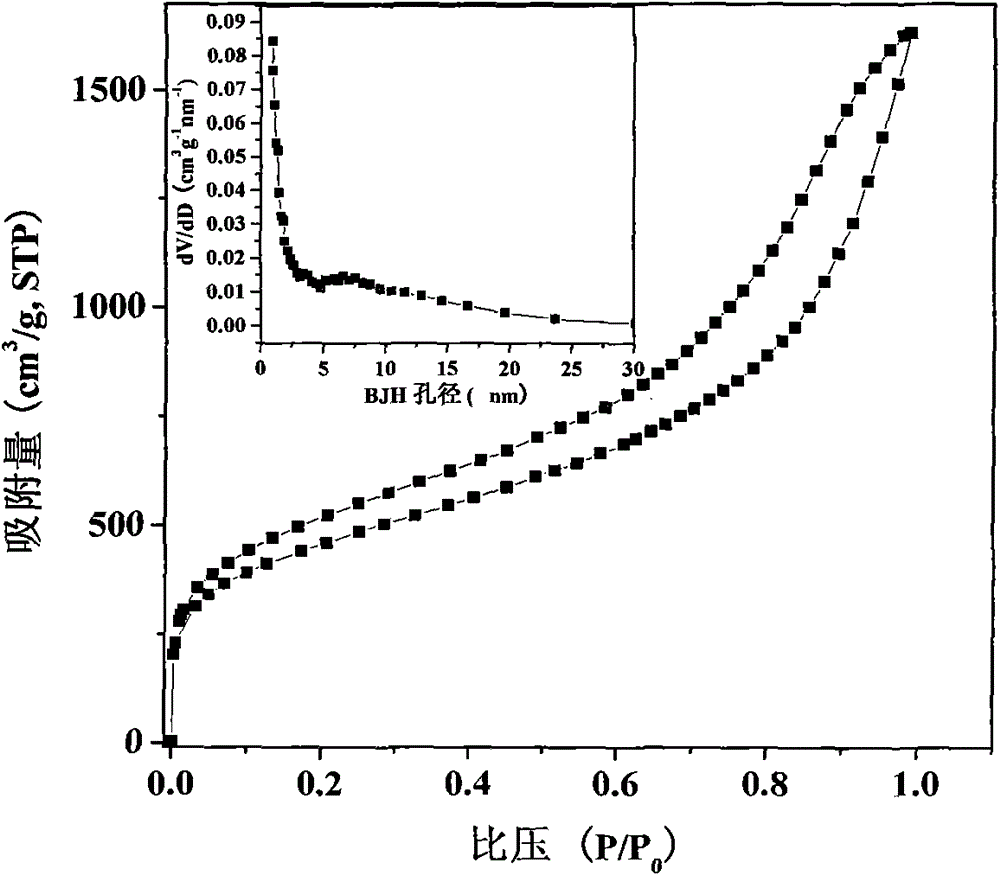

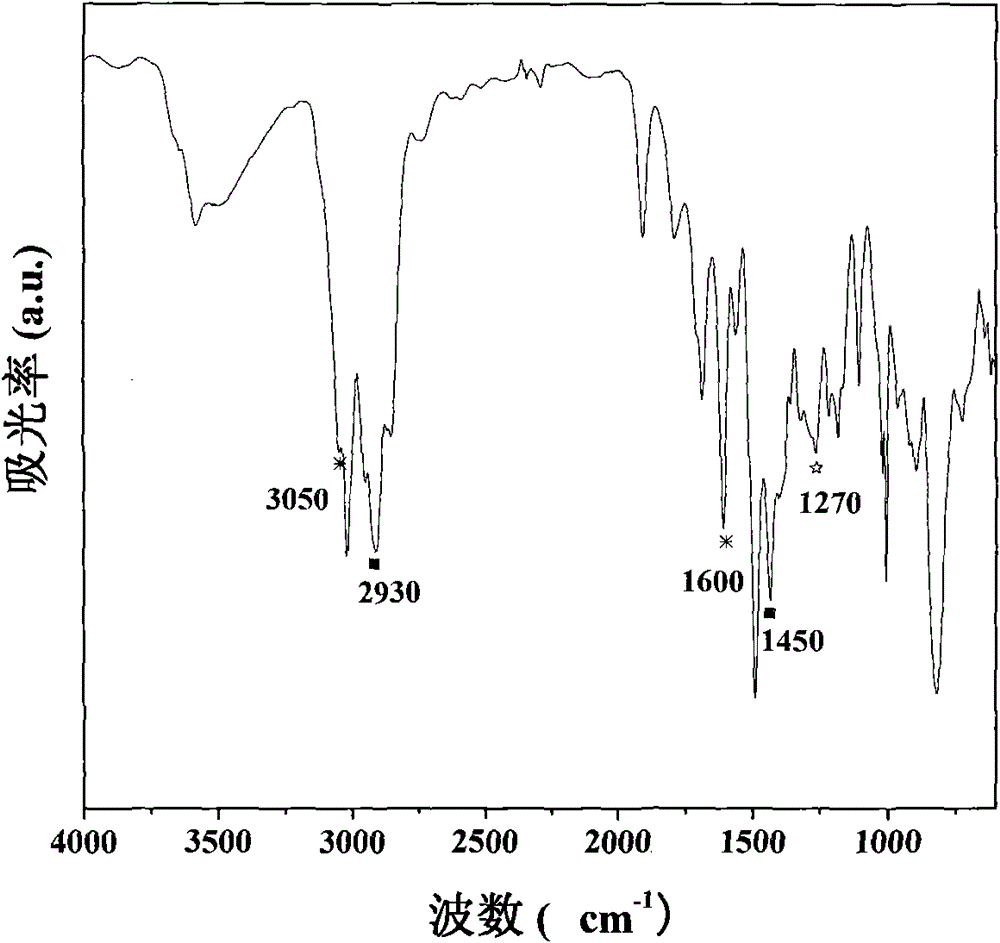

[0020] Example 1: Dissolve 5g of p-dichloromethylbenzene monomer in 50ml of dichloroethane, then add 2.5mL of n-hexane, add 2.645g of ferric chloride catalyst after it is completely dissolved, and heat up to 60 after stirring for 2 hours ℃, carry out Friedel-Crafts reaction for 8 hours, and after cooling at room temperature, the solid product is washed with acetone, acetone, hydrochloric acid, and distilled water in a Soxhlet extractor for 8 hours. The BET specific surface area of the adsorption resin is 1526cm 2 g -1 , the total pore volume is 1.687cm 3 g -1 .

Embodiment 2

[0021] Example 2: Dissolve 5g of 4,4'-dichloromethylbiphenyl monomer in 50ml of dichloroethane, then add 7.5mL of tetrahydrofuran, add 2.70g of ferric chloride catalyst after complete dissolution, and stir for 2 hours The temperature was raised to 70°C, and the Friedel-Crafts reaction was carried out for 10 hours. After cooling at room temperature, the solid product was sequentially washed with acetone, acetone, hydrochloric acid, and distilled water in a Soxhlet extractor for 8 hours. The BET specific surface area of the adsorption resin is 1756cm 2 g -1 , the total pore volume is 2.28cm 3 g -1 .

Embodiment 3

[0022] Example 3: Dissolve 5g of 4,4'-dichloromethylbiphenyl monomer in 50ml of ethylene dichloride, then add 10mL of n-hexane, add 3.22g of ferric chloride catalyst after complete dissolution, and stir for 2 hours Afterwards, the temperature was raised to 80° C., and the Friedel-Crafts reaction was carried out for 12 hours. After cooling at room temperature, the solid product was sequentially washed with acetone, acetone, hydrochloric acid, and distilled water in a Soxhlet extractor for 8 hours. The BET specific surface area of the adsorption resin is 1592cm 2 g -1 , the total pore volume is 2.526cm 3 g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com