Method for quickly preparing GdBCO film through chemical solution deposition

A chemical solution deposition, rapid technology, applied in the direction of solid-state chemical plating, manufacturing/processing of superconductor devices, coating, etc., can solve the problems of reduced production rate and increased uncontrollable factors, and achieve low cost and simple and easy preparation method Simple effect of operation and experimental setup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of GdBCO precursor solution: dissolving gadolinium acetate, barium trifluoroacetate and copper benzoate in methanol at an atomic ratio of Gd: Ba: Cu=1: 2: 3, then performing vacuum distillation to remove impurity water, and then Add chelating agent ethanolamine, finally obtain GdBCO precursor solution with methanol fixed solution; The total concentration of gadolinium, barium and copper metal ion in the described GdBCO precursor solution is 1mol / L, and the addition amount of described chelating agent ethanolamine is copper ion molar weight 5 times;

[0023] (2) Precursor solution coating: the GdBCO precursor solution described in step (1) is evenly coated on the lanthanum aluminate single crystal substrate by spin coating method, and then dried at a temperature of 120 ° C to obtain a surface adhesion of 1 μm Lanthanum aluminate single crystal substrate of cured film;

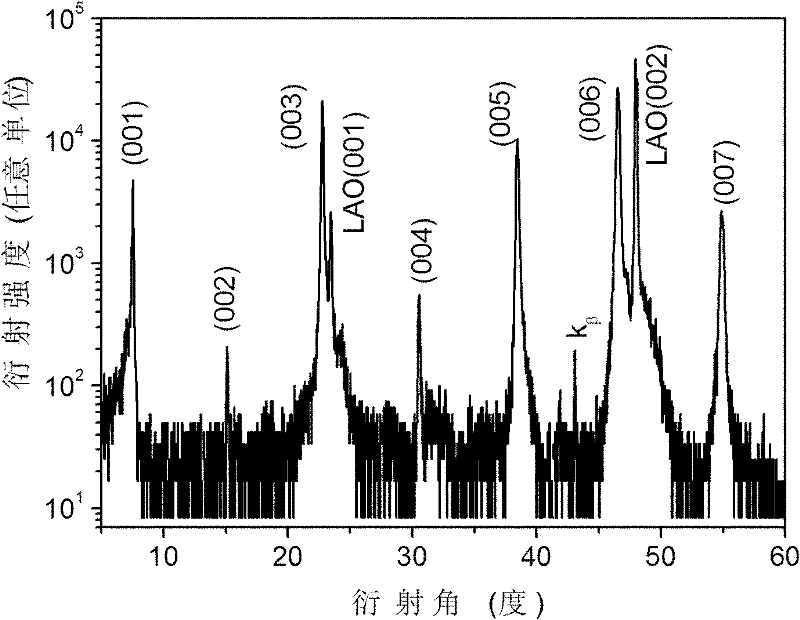

[0024] (3) High-temperature heat treatment: place the lanthanum aluminate single crys...

Embodiment 2

[0028] The preparation method of this embodiment is the same as that of Example 1, and the difference is that the chelating agent is triethanolamine, and the amount of the chelating agent added is 3 times the molar amount of copper ions; the drying temperature is 135°C, and the cured film The thickness is 1.5 μm; during the high temperature heat treatment process, the temperature is 800°C.

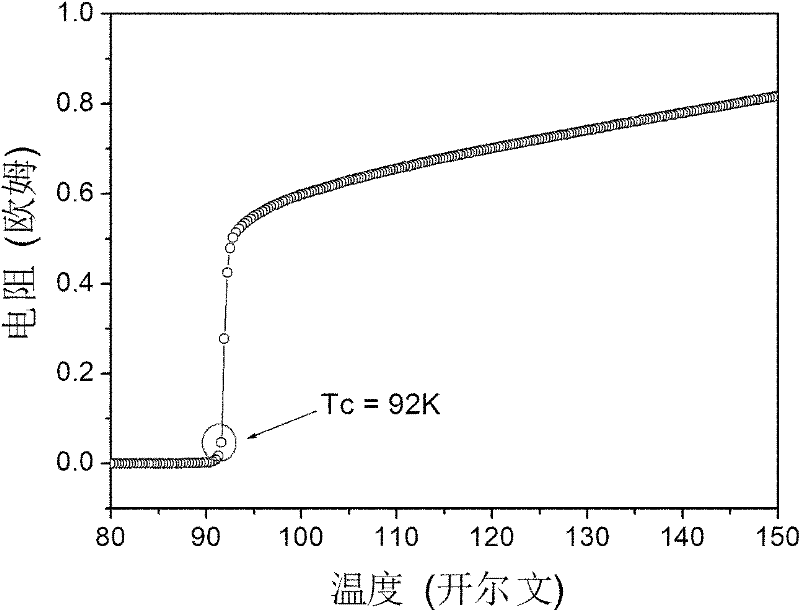

[0029] image 3 It is the resistance-temperature curve (R-T) figure of the LAO / GdBCO film prepared by the present embodiment (the ordinate is resistance, and the unit is ohm; The abscissa is temperature, and the unit is K), the results show that the film has a good superconducting transition, and the transition end temperature It is 92K; the Jc of the film is 1.8MA / cm under 77K zero field 2 , showing excellent performance.

Embodiment 3

[0031] (1) Preparation of GdBCO precursor solution: dissolving gadolinium acetate, barium trifluoroacetate and copper benzoate in methanol at an atomic ratio of Gd: Ba: Cu=1: 2: 3, then performing vacuum distillation to remove impurity water, and then Add the chelating agent triethanolamine, and finally obtain the GdBCO precursor solution with methanol fixed solution; the total concentration of gadolinium, barium and copper metal ions in the GdBCO precursor solution is 1.5mol / L, and the addition amount of the chelating agent triethanolamine is copper ion 5 times the molar weight;

[0032] (2) Precursor solution coating: uniformly coat the GdBCO precursor solution described in step (1) on the NiW / Y by dip coating method 2 O 3 / YSZ / CeO 2buffer layer, and then dried at a temperature of 150°C to obtain NiW / Y with a 2μm cured film attached to the surface 2 O 3 / YSZ / CeO 2 The buffer layer;

[0033] (3) High-temperature heat treatment: the NiW / Y surface with the cured film atta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com