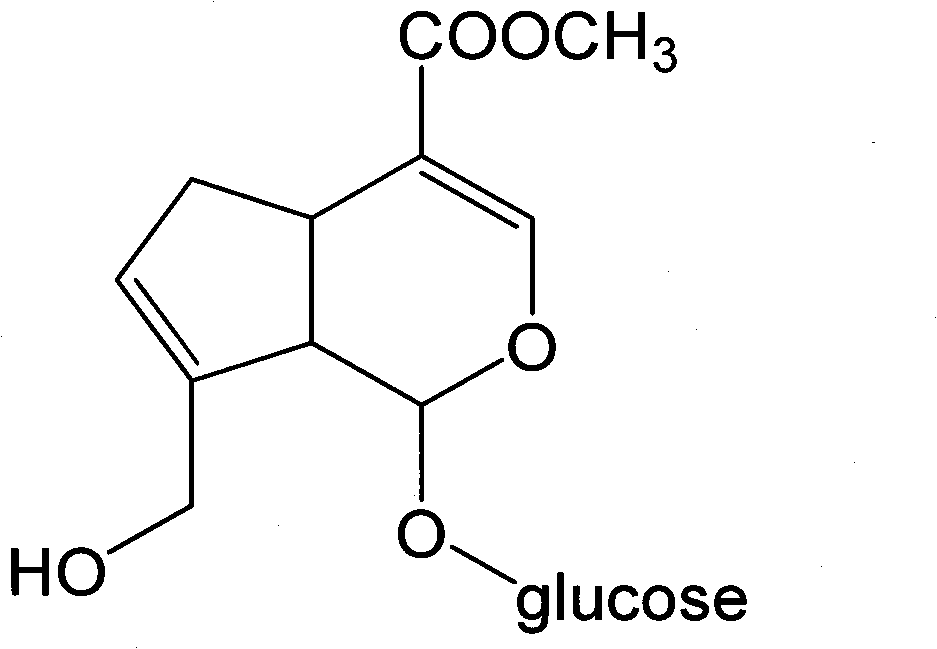

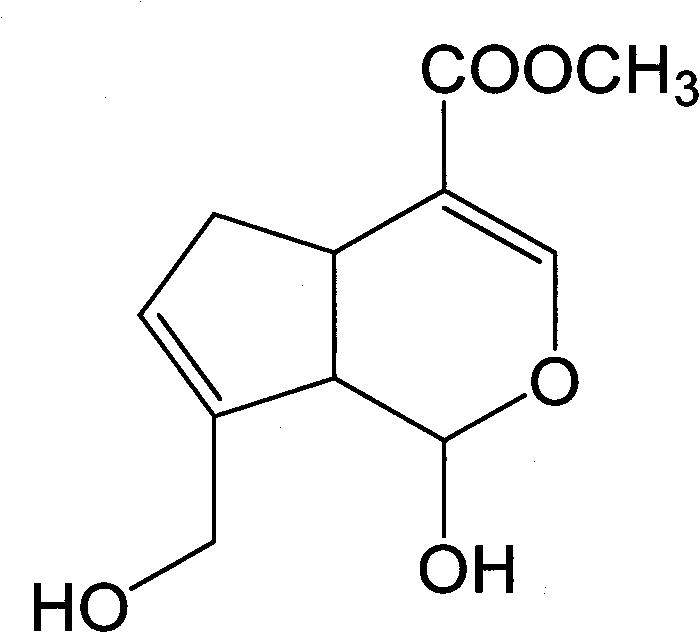

Method for preparing genipin

A technology of geniposide and glycoside hydrolase, which is applied in the direction of sustainable manufacturing/processing, immobilized on/in organic carriers, chemical industry, etc., and can solve the problem of industrial production of geniposide, β-glucose, etc. Problems such as high price of glucosidase and high dosage of β-glucosidase achieve the effect of high market price, difficulty in obtaining and reducing the generation of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

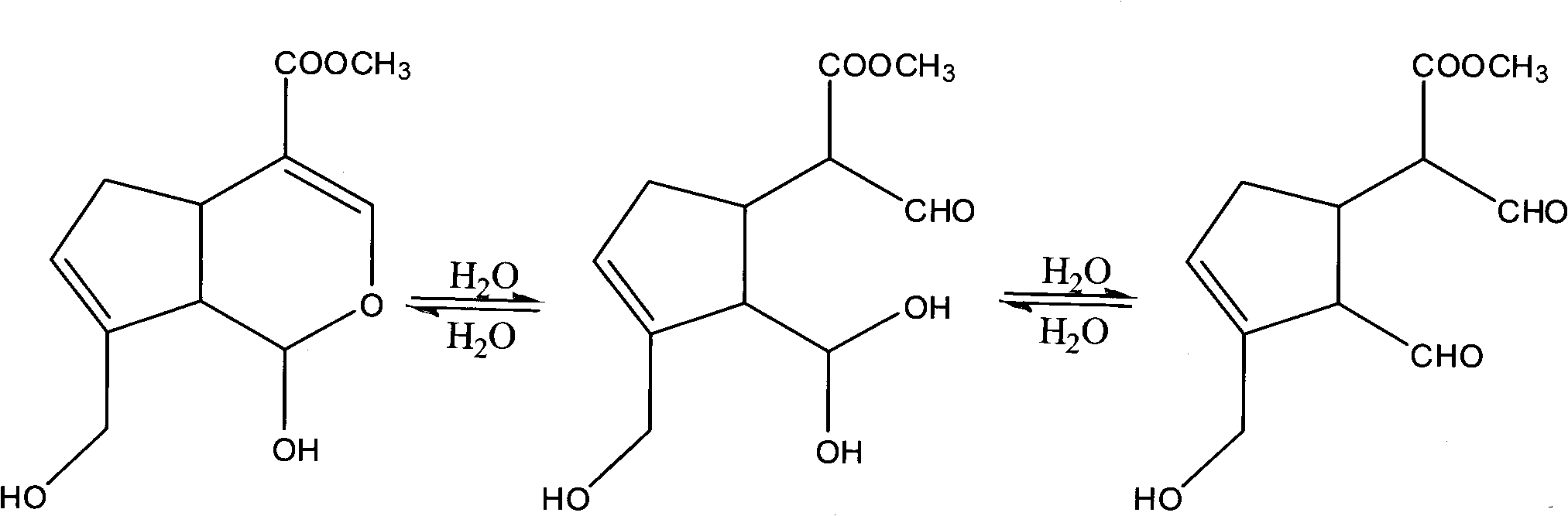

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The reaction of free-glucosidase single-phase system hydrolyzing geniposide, the experimental operation steps are as follows:

[0039] (1) Take 0.5 g of geniposide with a purity of 90%, put it in a round bottom flask, add 50 U of free β-glucosidase, 50 ml of acetic acid-sodium acetate buffer solution (pH 4.5), heat and stir in a water bath at 55°C for 2 hours.

[0040] (2) The reaction solution was extracted three times with 50 ml of ethyl acetate, and the ethyl acetate extracts were combined.

[0041] (3) Add an appropriate amount of anhydrous sodium sulfate to the combined ethyl acetate extracts, dry for 30 minutes, and filter.

[0042] (4) Ethyl acetate was recovered by rotary evaporation under reduced pressure, and concentrated to 5% of the original volume.

[0043] (5) Put the concentrated liquid at 0°C for crystallization, and recover the crystals.

[0044] (6) The crystals were vacuum-dried at 40° C. for 1 h, weighed and stored.

[0045] Experimental results: ...

Embodiment 2

[0047] The reaction of free β-glucanase biphasic system to hydrolyze geniposide, the experimental steps are as follows:

[0048] (1) Take 0.5g of geniposide with a purity of 90%, put it in a round bottom flask, add 45U of free β-glucanase, 50ml of acetic acid-sodium acetate buffer solution (pH 4.2) and 50ml of ethyl acetate, at 50°C Heated and stirred in a water bath for 2h.

[0049] (2) The reaction solution was extracted three times with 50 ml of ethyl acetate, and the ethyl acetate extracts were combined.

[0050] (3) Add an appropriate amount of anhydrous sodium sulfate to the combined ethyl acetate extracts, dry for 30 minutes, and filter.

[0051] (4) Ethyl acetate was recovered by rotary evaporation under reduced pressure, and concentrated to 5% of its original volume.

[0052] (5) Put the concentrated liquid at 0°C for crystallization, and recover the crystals.

[0053] (6) The crystals were vacuum-dried at 40° C. for 1 h, weighed and stored.

[0054] Experimental re...

Embodiment 3

[0056] Immobilized β-glucanase single-phase system hydrolyzes geniposide, and the experimental steps are as follows:

[0057] (1) Weigh 0.6g of sodium alginate and add 20ml of deionized water, heat to dissolve.

[0058] (2) Add 110 U of free β-glucanase in proportion and mix well.

[0059] (3) Then add 0.64 ml of 25% glutaraldehyde aqueous solution, stir and cross-link at room temperature for 2 hours.

[0060] (4) Use a syringe (No. 5 needle) to draw the above solution, drop it into 100ml of calcium chloride solution with a concentration of 0.5% at a height of about 10cm, form a smooth gel ball with a diameter of about 3mm, and let it stand to harden 2h.

[0061] (5) The immobilized enzyme gel particles were filtered out, washed with deionized water, blotted to dry the surface moisture, and stored in a refrigerator at 4°C.

[0062] (6) Take 0.25g of geniposide with a purity of 90%, put it in a round bottom flask, add 5U of immobilized β-glucanase, 25ml of acetic acid-sodium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com