Large-area growing method for single crystal titanium dioxide nano rod and application of nano rod

A technology of titanium dioxide and growth method, which is applied in the field of nanomaterials, can solve the problems of increasing process difficulty and high vacuum degree of reaction temperature, and achieve the effect of improving field enhancement factor, low turn-on electric field emission, and realizing turn-on electric field emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

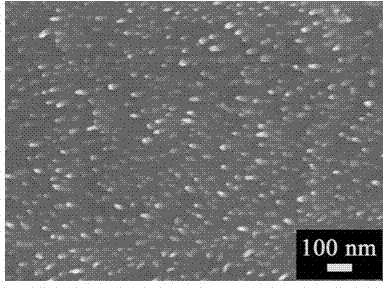

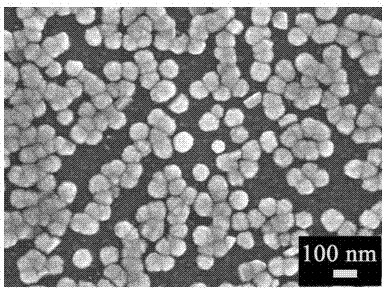

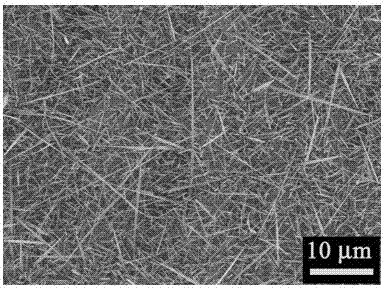

[0043]Take industrial pure titanium sheets, and clean them by ultrasonic in acetone and absolute ethanol solutions; according to the volume ratio of 1:4, respectively take concentrated hydrofluoric acid with a concentration of ≥40% and concentrated hydrochloric acid with a concentration of 36%, and mix them to form acid solution, put the cleaned titanium sheet into the acid solution, and chemically oxidize it for 3 minutes to form a titanium dioxide particle film on the surface of the titanium sheet, take out the titanium sheet, rinse it with deionized water, and blow it dry with nitrogen. SEM image, such as figure 1 As shown in the figure, granular titanium dioxide is generated on the surface of the oxidized titanium sheet. The chemically oxidized titanium sheet was used as a counter electrode in 0.1 M NiSO 4 ·6H 2 Electrochemical deposition in O solution for 180 s, metal nickel nanoparticles were deposited on the chemically oxidized titanium sheet, the DC voltage was contr...

Embodiment 2

[0045] Take industrial pure titanium sheet and clean it by ultrasonic in acetone and absolute ethanol solution in turn; according to the volume ratio of 1:8, take concentrated hydrofluoric acid with a concentration of ≥40% and concentrated hydrochloric acid with a concentration of 38%, respectively, and mix them to form acid solution, put the cleaned titanium sheet into the acid solution, and chemically oxidize it for 5 minutes to form a titanium dioxide particle film on the surface of the titanium sheet, take out the titanium sheet, rinse it with deionized water, and dry it with nitrogen; the chemically oxidized titanium sheet as a counter electrode, in 0.4 M NiSO 4 ·6H 2 Electrochemical deposition was carried out in O solution for 105 s, and metal nickel nanoparticles were deposited on the chemically oxidized titanium sheet. During the electrochemical deposition process, the DC voltage was controlled at 1.5 V. The titanium sheet was taken out, rinsed with deionized water, an...

Embodiment 3

[0047] Take industrial pure titanium sheet and clean it by ultrasonic in acetone and absolute ethanol solution in turn; take concentrated hydrofluoric acid with a concentration ≥ 40% and concentrated hydrofluoric acid with a concentration of 37% respectively according to the volume ratio 1:6, and mix them to form acid solution, put the cleaned titanium sheet into the acid solution, and chemically oxidize it for 1 min to form a titanium dioxide particle film on the surface of the titanium sheet, take out the titanium sheet, rinse it with deionized water, and dry it with nitrogen; the chemically oxidized titanium sheet as a counter electrode, in 0.25 M NiSO 4 ·6H 2 Electrochemical deposition was carried out in O solution for 200 s, and metal nickel nanoparticles were deposited on the chemically oxidized titanium sheet. During the electrochemical deposition process, the DC voltage was controlled at 1.85 V. The titanium sheet was taken out, rinsed with deionized water, and dried w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com