Water-based treatment agent for vulcanized shoes and preparation method thereof

A treatment agent and water-based technology, which is applied in the field of water-based treatment agent for vulcanized shoes and its preparation, can solve the problems of limited application of vulcanized shoes, moisture is not easy to volatilize, and unfavorable lamination, so as to improve anti-sag and anti-splash performance, The effect of reducing energy consumption and increasing bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 A kind of water-based treatment agent for vulcanized shoes

[0035] Consists of the following components by weight:

[0036] Waterborne polyurethane dispersion AD290 100 parts

[0037] Ethylene glycol monobutyl ether (cosolvent) 0.1 parts

[0038] Carbodiimide (hydrolysis resistance agent) 0.3 parts

[0039] Polyether NPE-108 (defoamer) 0.2 parts

[0040] Nano silica suspension (adhesion promoter, particle size is 60nm) 3 parts

[0041] TRM103S (non-ionic associative polyurethane thickener) 0.1 parts

[0042] ASE-60 (alkali-swellable thickener) 0.1 parts

[0043] In this example, all raw materials are commercially available products: water-based polyurethane dispersion AD290: Shanghai Zhonghaojing Industrial Co., Ltd.; ethylene glycol monobutyl ether: Guangzhou Baofeng Chemical Trading Co., Ltd.; carbodiimide: Guangzhou Hong Hua Chemical Co., Ltd.; defoamer polyether NPE-108: Nantong Xinbaoyuan Chemical Co., Ltd.; nano-silica suspension: Hangzhou Wanj...

Embodiment 2

[0070] Embodiment 2 A kind of aqueous treatment agent for vulcanized shoes

[0071] Consists of the following components by weight:

[0072] Waterborne polyurethane dispersion AD290 100 parts

[0073] Ethylene glycol monoethyl ether (cosolvent) 0.3 parts

[0074] Carbodiimide (hydrolysis resistance agent) 0.3 parts

[0075] Polyether BYK-022 (defoamer) 0.4 parts

[0076] Adhesion promoter (nano silicon dioxide suspension, particle size is 80nm) 5.0 parts

[0077] PUR-62 (non-ionic associative polyurethane thickener) 0.1 parts

[0078] DR-1 (alkali-swellable thickener) 0.2 parts

[0079] All the above raw materials are commercially available.

[0080] The preparation method of the aqueous treatment agent in this example is the same as that in Example 1.

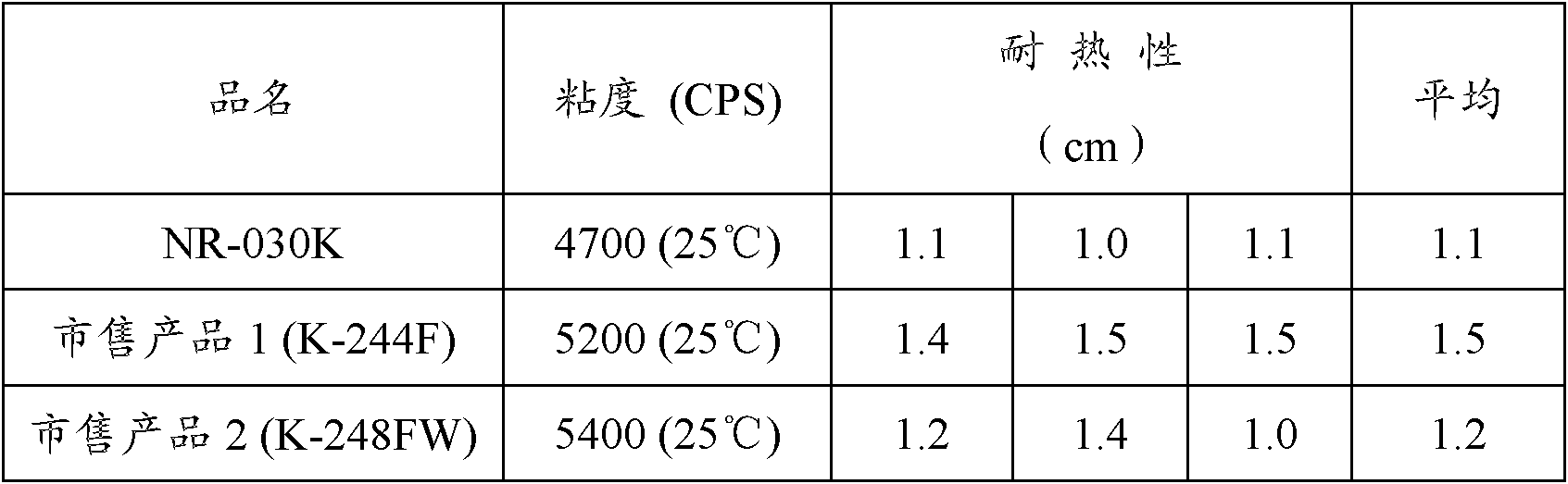

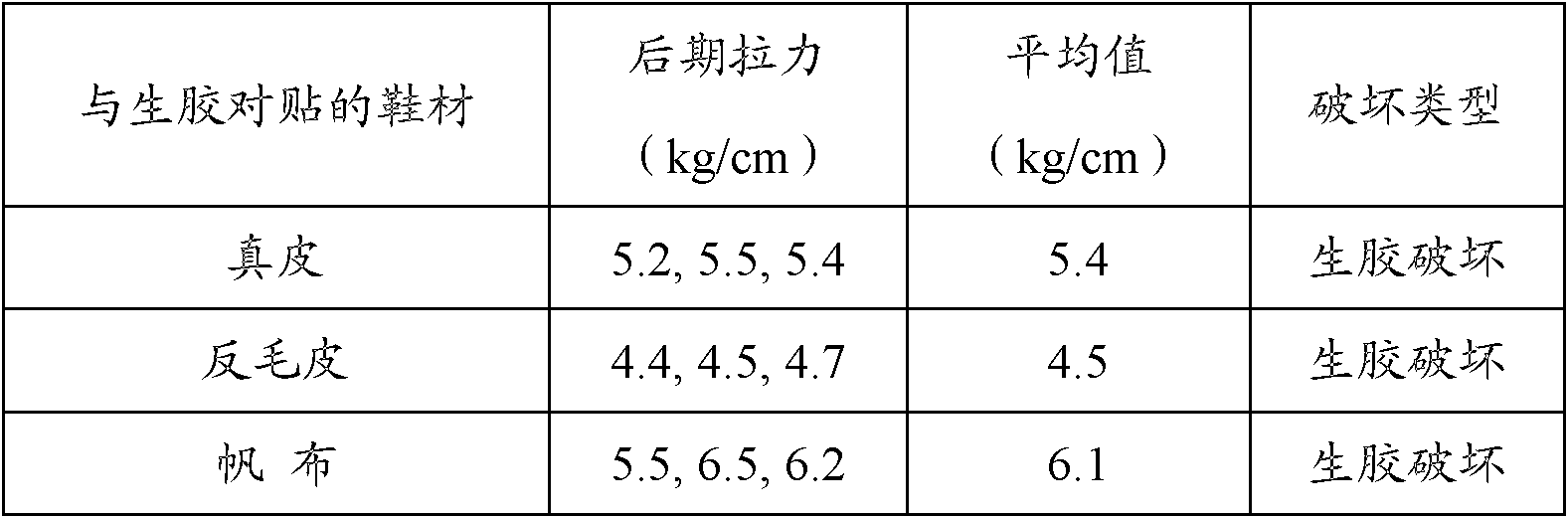

[0081] The heat resistance and bonding strength of the water-based treatment agent of this embodiment are similar to those of Embodiment 1, and both exceed the highest standard in the vulcanized shoe industry. The wate...

Embodiment 3

[0082] Embodiment 3 A kind of water-based treatment agent for vulcanized shoes

[0083] Consists of the following components by weight:

[0084] Waterborne polyurethane dispersion AD290 100 parts

[0085] Ethylene glycol monobutyl ether and ethylene glycol isopropyl ether (co-solvent) 0.3 parts

[0086] Carbodiimide (hydrolysis resistance agent) 0.5 parts

[0087] Polyether BYK-025 (defoamer) 0.5 parts

[0088] Adhesion promoter (nano-silica suspension, particle diameter of 8 parts is 40nm)

[0089] RM-12W (non-ionic associative polyurethane thickener) 0.2 parts

[0090] RM-2020 (non-ionic associative polyurethane thickener) 0.2 parts

[0091] All the above raw materials are commercially available.

[0092] The preparation method of the aqueous treatment agent in this example is the same as that in Example 1.

[0093] The water-based treatment agent in this example has better heat resistance than the water-based treatment agent in Example 2, and is especially suitable f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com