TiO2-ZrO2 composite oxide thin film ultraviolet detector and preparation method thereof

A composite oxide, tio2-zro2 technology, applied in the direction of semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., to achieve the effects of improving quality, process compatibility, and reducing surface state density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

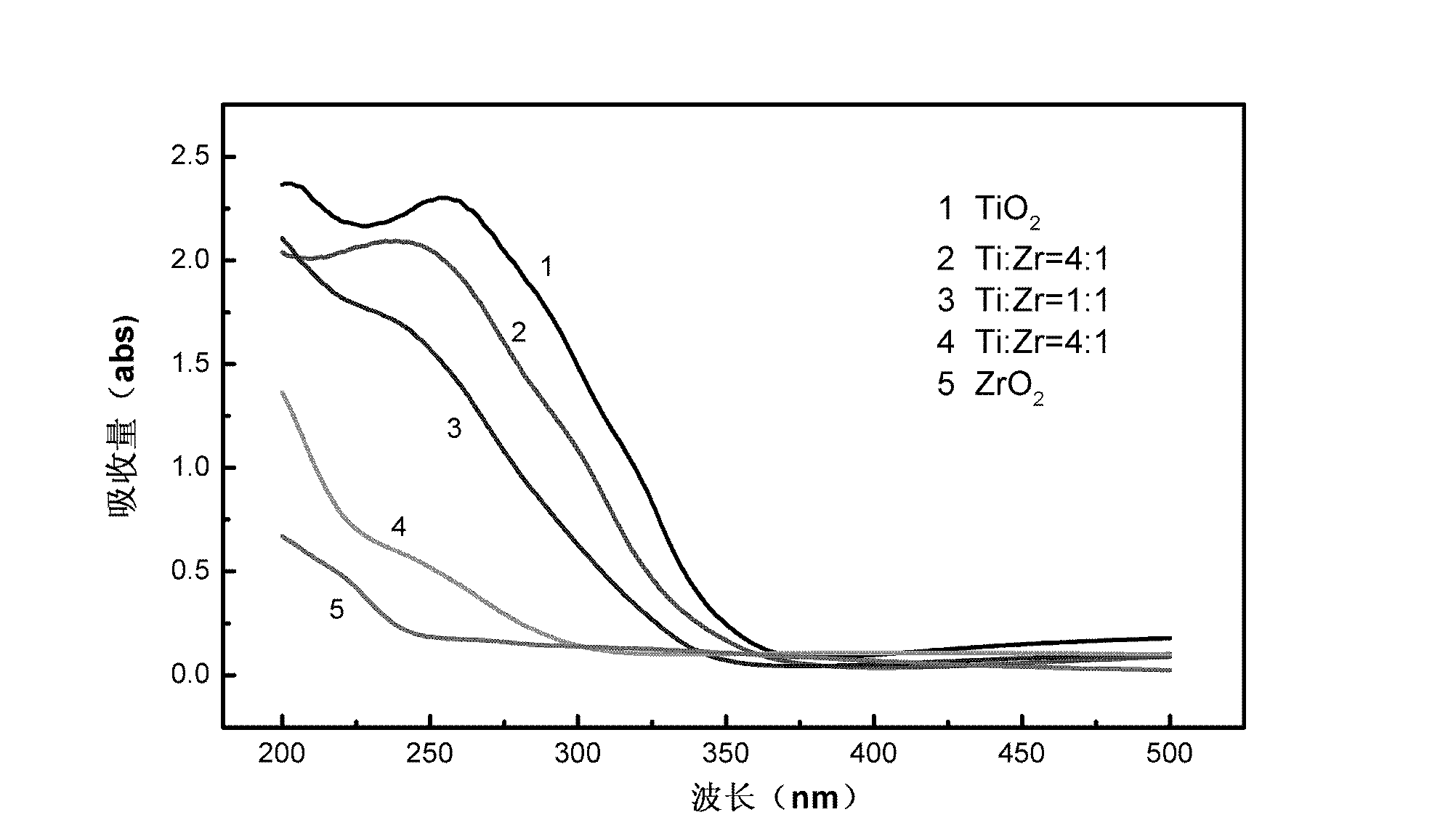

[0033] Preparation of TiO by Sol-Gel Technology 2 -ZrO 2 Composite oxide sol, respectively add 2.4mL tetrabutyl zirconate and 7.6mL tetrabutyl titanate to 100mL absolute ethanol at room temperature, then add dropwise 10mL glacial acetic acid as a catalyst, after 60 minutes of stirring, a uniform and transparent Slowly add 10mL of acetylacetone to inhibit hydrolysis, the color of the solution becomes darker, continue to stir for 1 hour; finally 10mL of deionized water is slowly added dropwise to the above solution at a rate of 1mL / min, and continue to stir for 2 hours to obtain Uniform and transparent pale yellow sol, it was left to age for 6 hours.

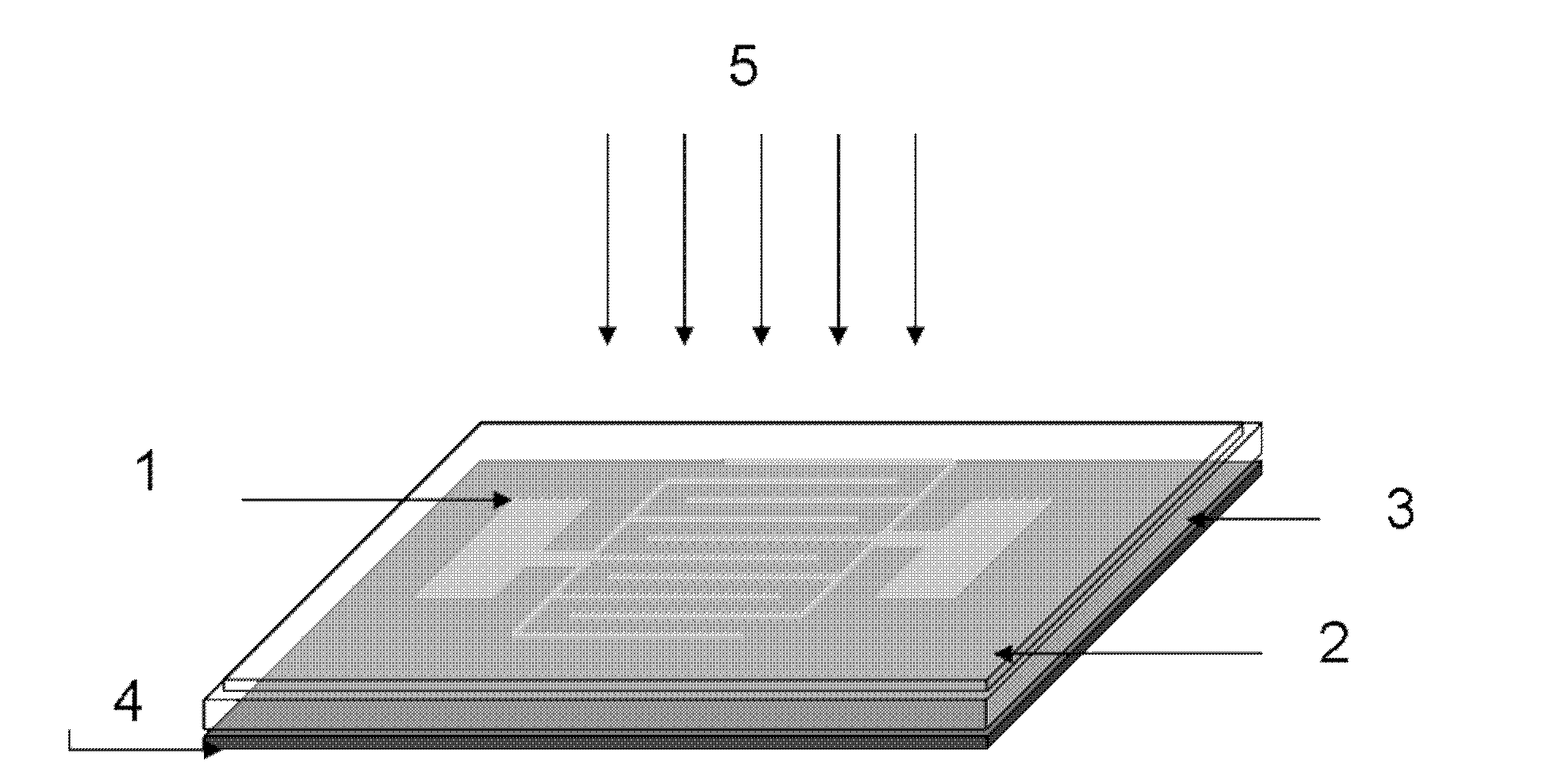

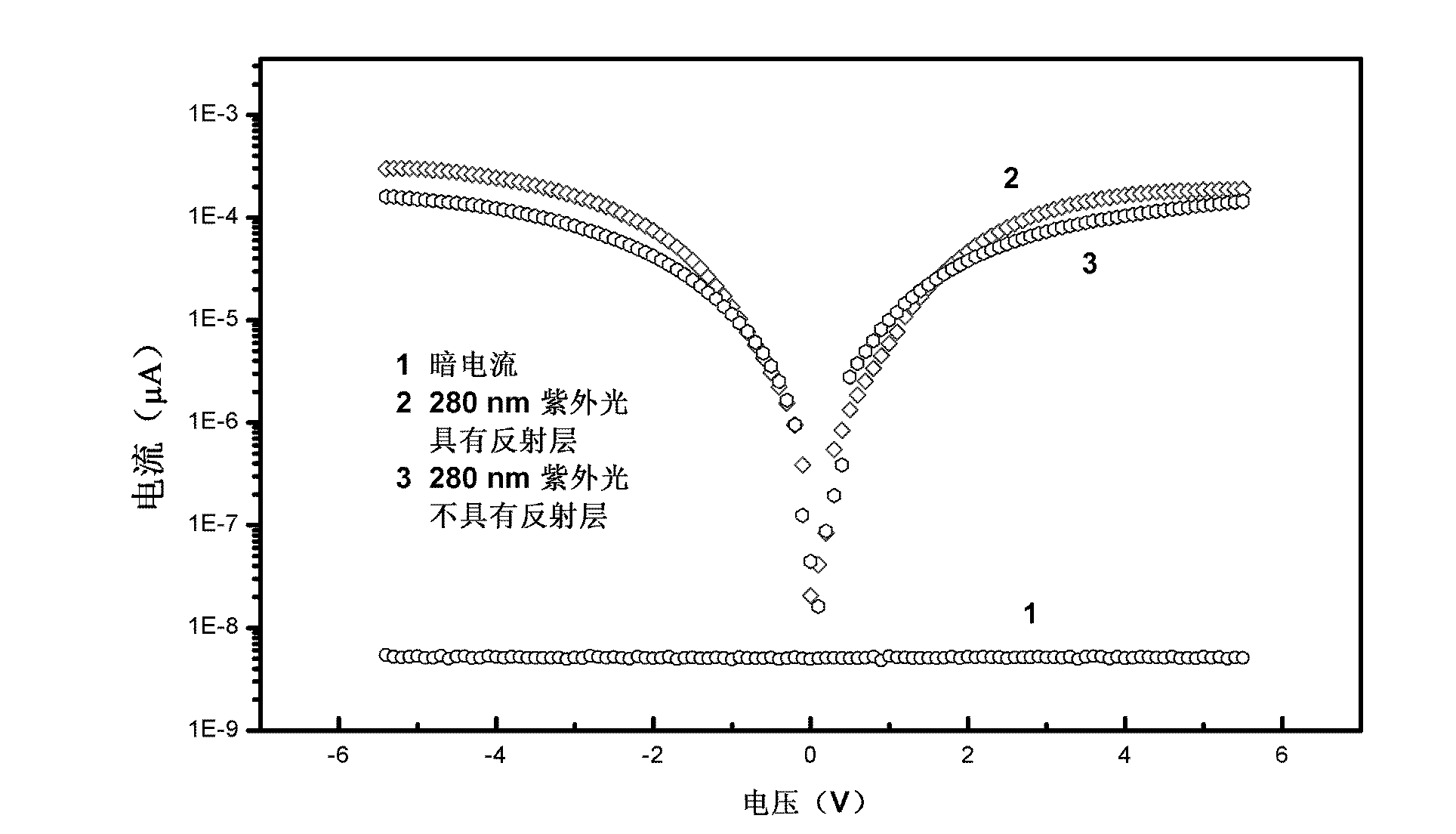

[0034] The aged TiO was spin-coated 2 -ZrO 2 The composite oxide sol was spin-coated on the cleaned quartz substrate, and then dried in an oven at 120 ° C for 10 minutes at a spin-coating speed of 3000 rpm. The above spin-coating and drying process was repeated 5 times, and finally the film was placed on the Sinter in a muffle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com