Garbage percolate treatment technology

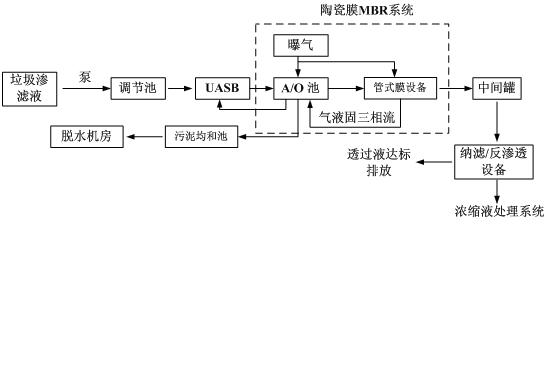

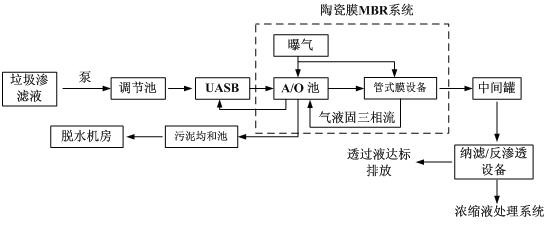

A technology for landfill leachate and treatment process, applied in the field of high-concentration organic wastewater treatment, can solve problems such as failure to meet national sewage discharge standards, membrane easily polluted, system instability, etc., to improve biochemical efficiency and membrane anti-pollution performance, water quality. Stable, low inflow requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Take the treatment method of landfill leachate in Jiangning area of Nanjing as an example:

[0033] (1) Pretreatment: transport the collected landfill leachate to the adjustment tank for sedimentation or sedimentation treatment;

[0034] Wherein, the total residence time of the landfill leachate in the regulating tank is 12 days.

[0035] (2) Anaerobic treatment: The supernatant of the landfill leachate is pumped and transported to the upflow anaerobic sludge bed (UASB) for anaerobic reaction to generate biogas, sewage and sludge.

[0036] (3) Gas-enhanced ceramic membrane bioreactor treatment: The sewage obtained after anaerobic treatment is sent to the ceramic membrane MBR system for treatment. The sewage is first transported to the A / O tank, where denitrification reaction is carried out in the denitrification tank, and the denitrified sewage overflows into the nitrification tank for nitrification reaction, and the sludge concentration in the A / O tank is controlled...

Embodiment 2

[0044] The concrete method of the present embodiment and detection are identical with embodiment 1, only change operating parameter as follows:

[0045]The total residence time of the landfill leachate in the regulating tank is 10 days; the filtration precision of the inorganic ceramic membrane ultrafiltration membrane is 20 nm; The aeration rate is 30%; the flow rate of the ultrafiltration membrane in the tubular membrane equipment for solid-liquid separation of sewage is 1 m / s, and the operating pressure is 0.5MPa.

Embodiment 3

[0047] The concrete method of the present embodiment and detection are identical with embodiment 1, only change operating parameter as follows:

[0048] The total residence time of the landfill leachate in the regulating tank is 15 days; the filtration accuracy of the inorganic ceramic membrane ultrafiltration membrane is 500 nm; The aeration rate is 10%; the flow rate of the ultrafiltration membrane in the tubular membrane equipment for solid-liquid separation of sewage is 7 m / s, and the operating pressure is 0.1MPa.

[0049] The purified water detection data of Examples 2 and 3 are also better than the discharge standard (GB16889-2008).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com