Method for preparing lithium nickel cobalt aluminum oxides serving as lithium ion battery positive electrode material

A lithium-nickel-cobalt-aluminum-oxygen, lithium-ion battery technology, which is applied in the fields of energy storage materials and electrochemistry, can solve the problems of low reversible capacity of positive electrode materials, difficult to precipitate large spherical particles, and difficult to filter flocculent precipitates, so as to protect cobalt resources. , The effect of reducing the cost of raw materials and improving the volumetric energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

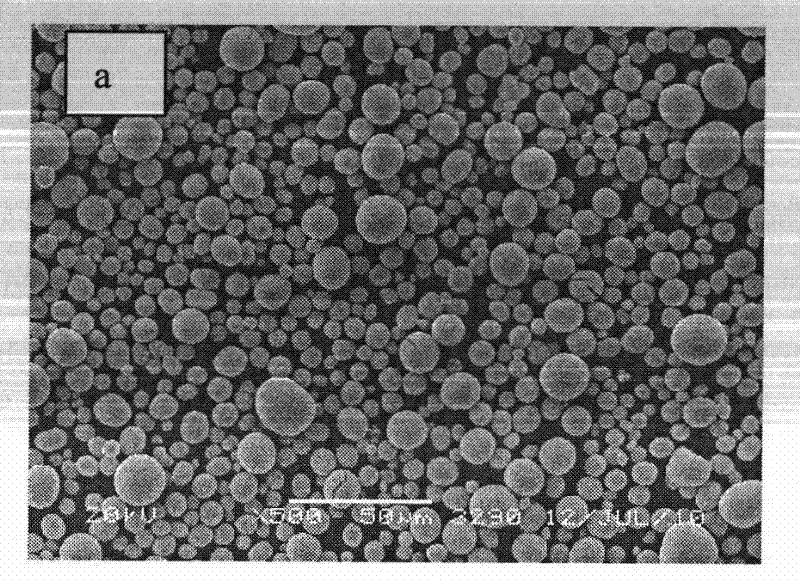

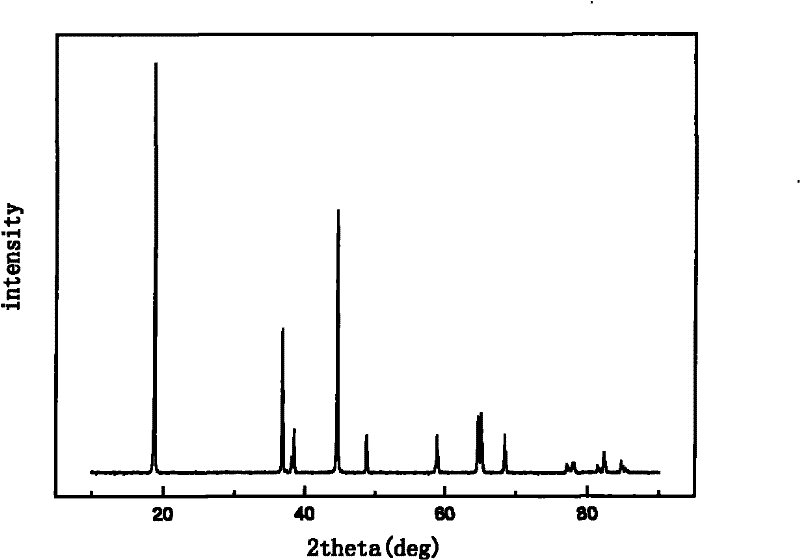

[0044] (1) Using nickel sulfate, cobalt sulfate, and aluminum sulfate as raw materials, according to Ni: Co: Al molar ratio 0.70: 0.25: 0.05, prepare spherical nickel-cobalt-aluminum composite hydroxide precursor by co-precipitation method;

[0045] (2) Put the nickel-cobalt-aluminum composite hydroxide precursor in a resistance furnace, raise the temperature to 300°C at a rate of 8°C / min, keep it warm for 1 hour, and pre-oxidize in an oxygen atmosphere to obtain a nickel-cobalt-aluminum composite oxide Li m Ni 1-x-y co x Al y o 2 , x=0.25, y=0.05, m=1.0;

[0046] (3) Mix the composite oxide of nickel-cobalt-aluminum and lithium hydroxide according to the atomic ratio n Li:(n Ni +n Co +n Al ) = 1.10: 0.80 mixed in a ratio of 1.10: 0.80, using ethanol as the ball milling medium, ball milling for 3 hours evenly, after drying, place it in a resistance furnace, slowly heat up to 600°C in an oxygen atmosphere, keep the temperature for 10 hours, cool naturally, crush, classi...

Embodiment 2

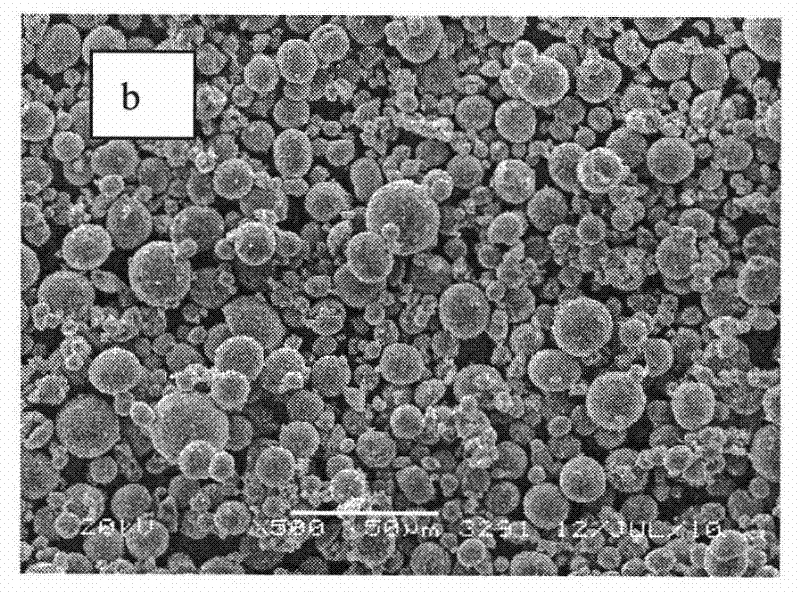

[0048] (1) Using nickel sulfate, cobalt sulfate, and aluminum sulfate as raw materials, according to Ni: Co: Al molar ratio 0.73: 0.25: 0.02, prepare spherical nickel-cobalt-aluminum composite hydroxide precursor by co-precipitation method;

[0049] (2) Put the composite hydroxide precursor of nickel-cobalt-aluminum in a resistance furnace, raise the temperature to 350°C at a rate of 8.5°C / min, keep it warm for 2 hours, and pre-oxidize in an oxygen atmosphere to obtain a composite oxide of nickel-cobalt-aluminum Li m Ni 1-x-y co x al y o 2 , x=0.25, y=0.02, m=1.0;

[0050] (3) Mix the composite oxide of nickel-cobalt-aluminum and lithium hydroxide according to the atomic ratio n Li :(n Ni +n Co +n Al ) = 1.10: 0.90 mixed in a ratio of 1.10:0.90, with ethanol as the ball milling medium, ball milled for 3.5 hours to be uniform, dried, placed in a resistance furnace, slowly heated to 620°C in an oxygen atmosphere, kept at a constant temperature for 11 hours, naturally coo...

Embodiment 3

[0052] (1) Using nickel sulfate, cobalt sulfate, and aluminum sulfate as raw materials, according to Ni: Co: Al molar ratio 0.75: 0.20: 0.05, prepare spherical nickel-cobalt-aluminum composite hydroxide precursor by co-precipitation method;

[0053] (2) Put the nickel-cobalt-aluminum composite hydroxide precursor in a resistance furnace, raise the temperature to 400°C at a rate of 9°C / min, keep it warm for 3 hours, and pre-oxidize in an oxygen atmosphere to obtain a nickel-cobalt-aluminum composite oxide Li m Ni 1-x-y co x al y o 2 , x=0.20, y=0.05, m=0.98;

[0054] (3) Mix the composite oxide of nickel-cobalt-aluminum and lithium hydroxide according to the atomic ratio n Li :(n Ni +n Co +n Al ) = 1.15: 0.95, mixed in a ratio of 1.15:0.95, using ethanol as the ball milling medium, milled for 3.5 hours evenly, dried, placed in a resistance furnace, slowly heated up to 650°C in an oxygen atmosphere, kept at a constant temperature for 15 hours, cooled naturally, crushed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com