Preparation method of ethoxylated trimethylolpropane triacrylic ester

A technology of ethoxylated trimethylolpropane triacrylate and cyclohexane, which is applied in the field of preparation of ethoxylated trimethylolpropane triacrylate, can solve the problems of not having product adjustment functions, and achieve Reduce environmental damage, less irritation, and less environmental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of ethoxylated trimethylolpropane triacrylate, the steps are:

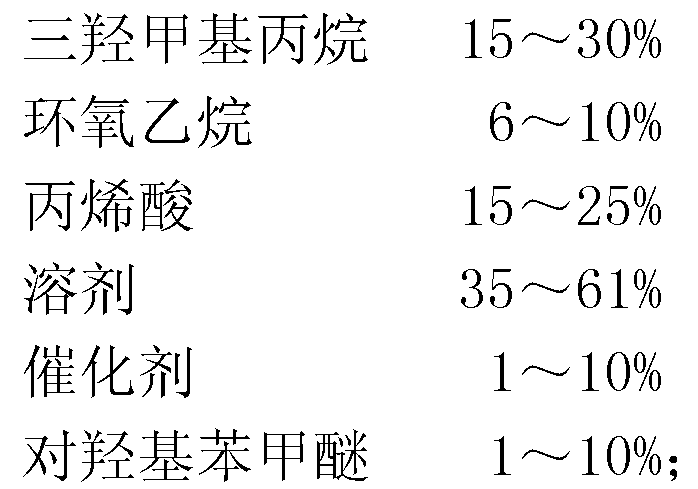

[0026] (1). Put the following components into the reaction kettle in turn according to the following weight ratio:

[0027]

[0028] (2) Then put the following components into the reaction kettle in sequence according to the content:

[0029] Phenothiazine 50ppm

[0030] Hydroquinone 150ppm

[0032] (3) The above-mentioned components are fully mixed and stirred in the reactor, and the steam valve is opened to heat slowly, and the heating rate is controlled so that the vapor pressure is 0.3-0.5MPa; the reaction temperature is controlled at 70°C within 1 hour and reacted for 4 hours; Continue the reaction when the temperature rises to 110-116° C., and the reaction ends when the reflux reaches about 6 hours. Take a sample for detection. When the acid value is about 10-40, it indicates that the reaction is over.

[0033] (4) add 15% strongly basic anion...

Embodiment 2

[0037] A preparation method of ethoxylated trimethylolpropane triacrylate, the steps are:

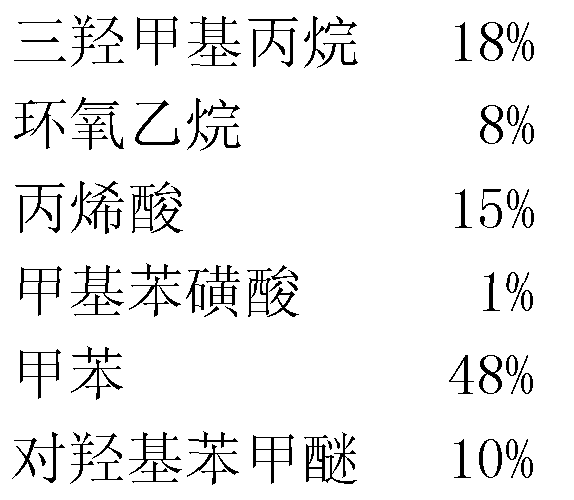

[0038] (1). Put the following components into the reaction kettle in turn according to the following weight ratio:

[0039]

[0040] (2) Then put the following components into the reaction kettle in sequence according to the content:

[0041] Phenothiazine 300ppm

[0042] Hydroquinone 100ppm

[0044] (3) Mix the above components in the reactor, then open the steam valve to heat slowly, and control the air pressure to 0.3-0.5MPA; within 1 hour, the reaction temperature is controlled at 80°C and reacted for 3 hours, when the temperature rises to 110-116°C React for 5 hours and the reaction ends when the temperature rises to 118-120°C. Take a sample for inspection. When the acid value is about 10-40, it indicates that the reaction is over;

[0045] (4) Add 20% strongly basic anion exchange resin (D296 type) to the reaction kettle to neutralize to neutr...

Embodiment 3

[0048] A preparation method of ethoxylated trimethylolpropane triacrylate, the steps are:

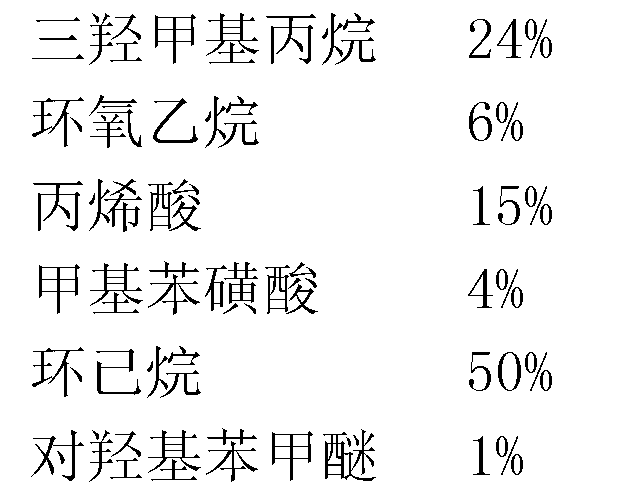

[0049] (1). Put the following components into the reaction kettle in turn according to the following weight ratio:

[0050]

[0051] (2) Then put the following components into the reaction kettle in sequence according to the content:

[0052] Phenothiazine 300ppm

[0053] Hydroquinone 100ppm

[0055] (3) The above-mentioned components are fully mixed and stirred in the reactor, and the steam valve is opened to heat slowly, and the heating rate is controlled so that the vapor pressure is 0.3-0.5MPa; the reaction temperature is controlled at 90°C within 1 hour and reacted for 4 hours; When the temperature rises to 110-116°C, continue to react for 6 hours, take a sample for detection, and when the acid value is about 10-40, it indicates that the reaction is over;

[0056] (4) Add 25% strongly basic anion exchange resin (D296 type) to neutralize to neut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com