Self-cleaning low-radiation Fresnel lens manufacturing method and concentration photovoltaic system based on self-cleaning low-radiation Fresnel lens

The technology of a Fresnel lens and its manufacturing method, which is applied in the field of solar energy utilization, can solve the problems of high battery sheet temperature, achieve the effects of reducing maintenance costs, benefiting photoelectric conversion efficiency, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation method of self-cleaning LOW-E glass:

[0037] (1) The low-e film surfaces of two pieces of LOW-E glass are relatively placed, and the surroundings of the two relatively placed LOW-E glasses are sealed with paraffin to protect the low-e film surfaces, and obtain module 1;

[0038] (2) Put the module I into the titanium sol and pull it at a speed of 1-30cm / min;

[0039] (3) remove the paraffin of the module 1 that titanium sol has been processed;

[0040] (4) Calcining the Low-E glass treated with the above-mentioned titanium sol at 450° C. for 45 minutes, and cooling to obtain the self-cleaning Low-E glass. The composition of the titanium sol is tetrabutyl titanate:ethanol:water:nitric acid:acetylacetone=0.9:17:2:0.3:0.6. The configuration of titanium sol can be carried out at room temperature.

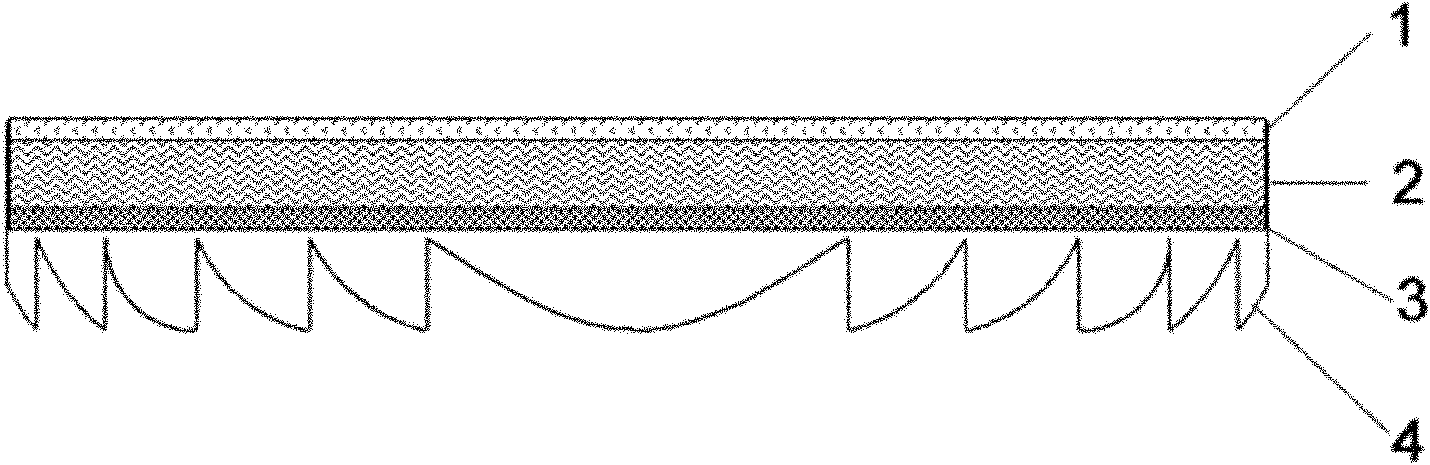

[0041] The fabrication method of self-cleaning low-emissivity Fresnel lens is as follows:

[0042] (1) Adding transparent optical silica gel to the forming mold ...

Embodiment 2

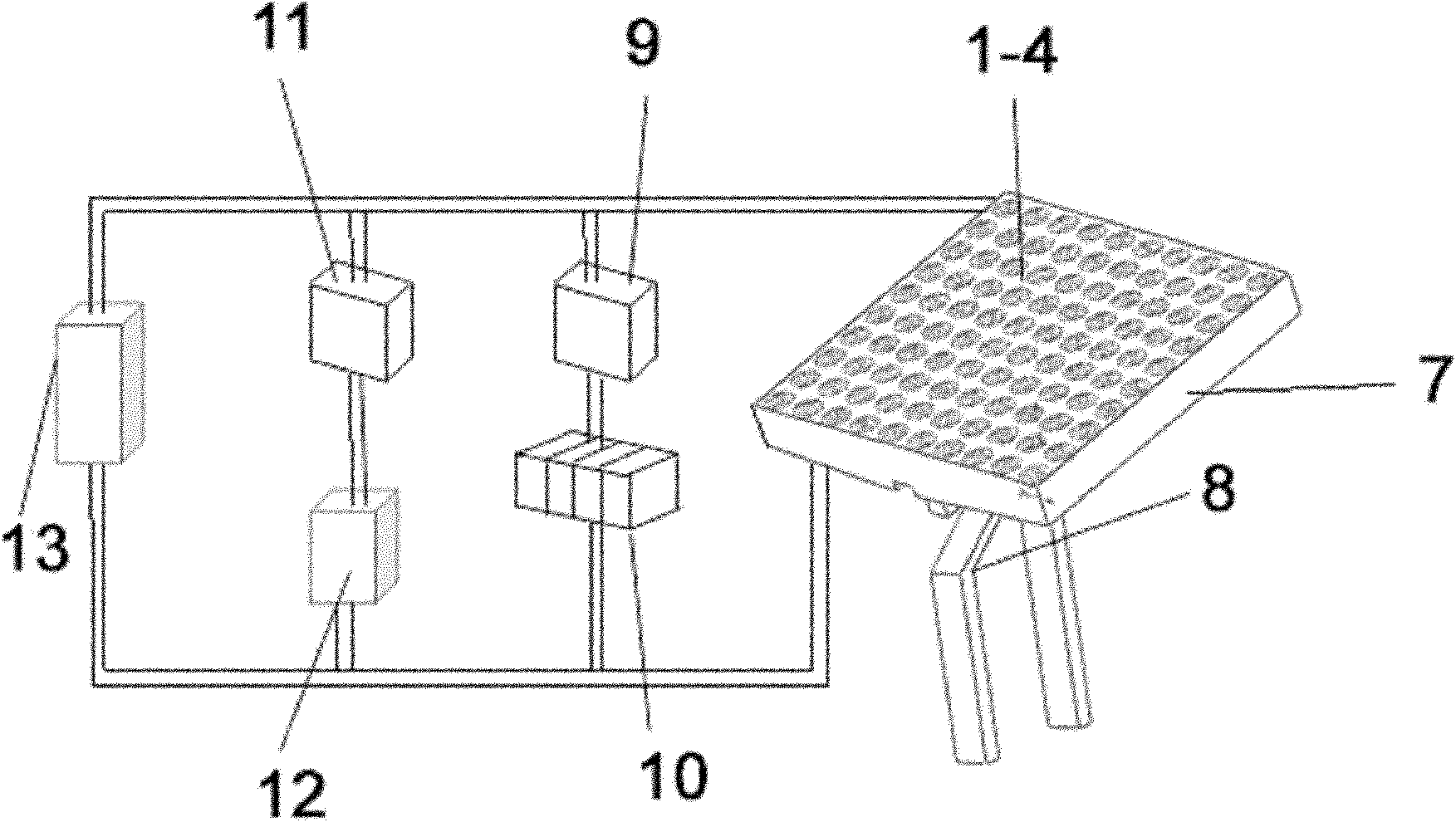

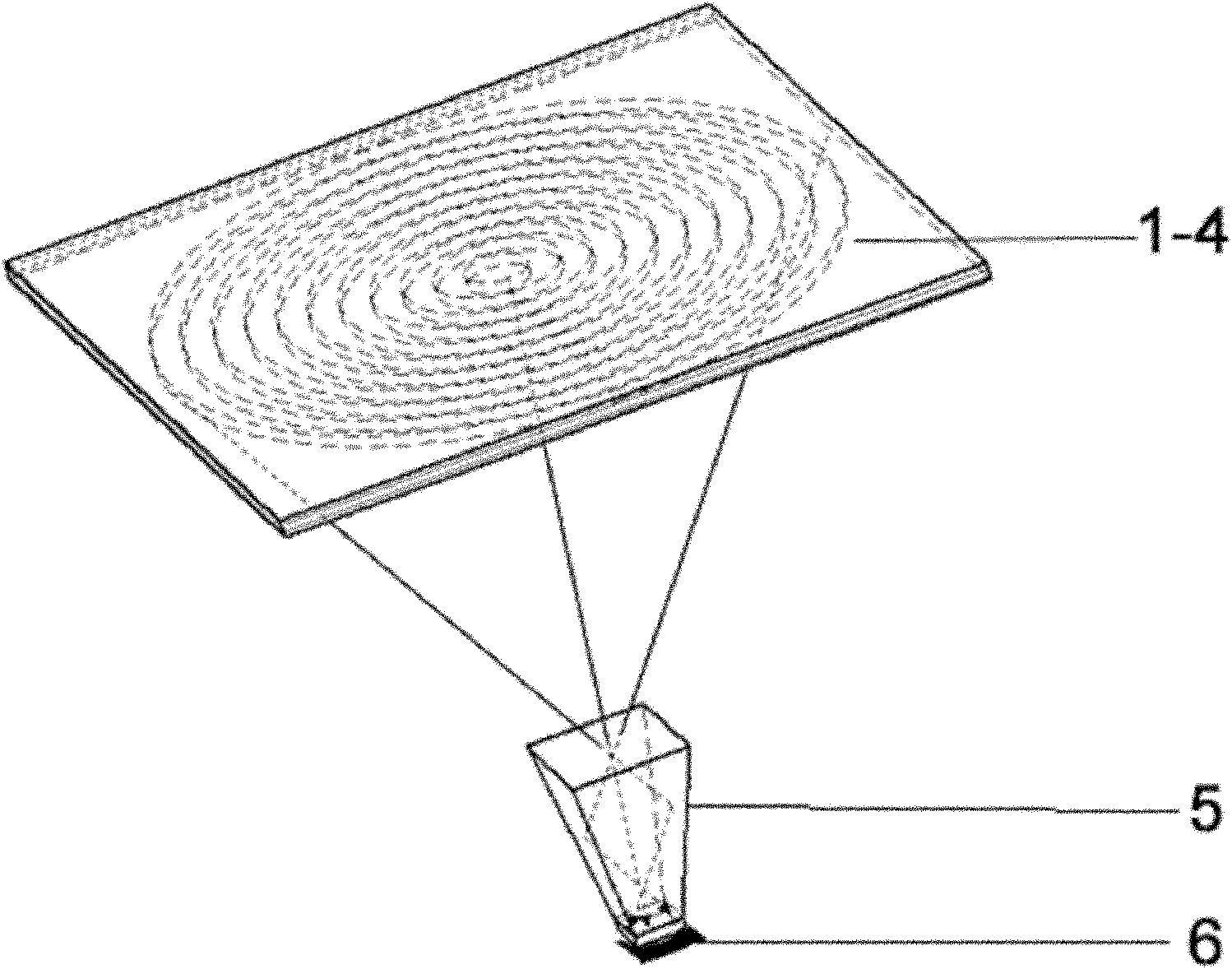

[0048] Assembly of a 500x Concentrating Photovoltaic System Based on a Self-Cleaning Low-E Fresnel Lens

[0049] The structural diagram of the concentrated photovoltaic system is shown in figure 2 , the structural diagram of the internal components of the aluminum alloy box is shown in image 3 . Concentrating photovoltaic system includes: self-cleaning low-radiation Fresnel lens 1-4, secondary uniform light prism 5, gallium arsenide cell 6, aluminum alloy box 7, tracking system 8, charge and discharge controller 9, battery pack 10. AC load 11, inverter 12 and DC load 13; the entire aluminum alloy box 7 is fixedly connected to the tracking system 8, the two ends of the aluminum alloy box 7 form a connection circuit with the DC load 13, and the AC load 11 and the inverter After the inverter 12 is connected in sequence, the charge-discharge controller 9 and the storage battery pack 10 are connected in sequence, respectively, and the DC load 12 are connected to the above-menti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap