Method for extracting and separating ions in two valence states of the same element in three phases

A technology of elements and valence states, applied in the direction of liquid solution solvent extraction, etc., to achieve the effects of eliminating interference, avoiding spectral overlap, and being easy to recycle and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

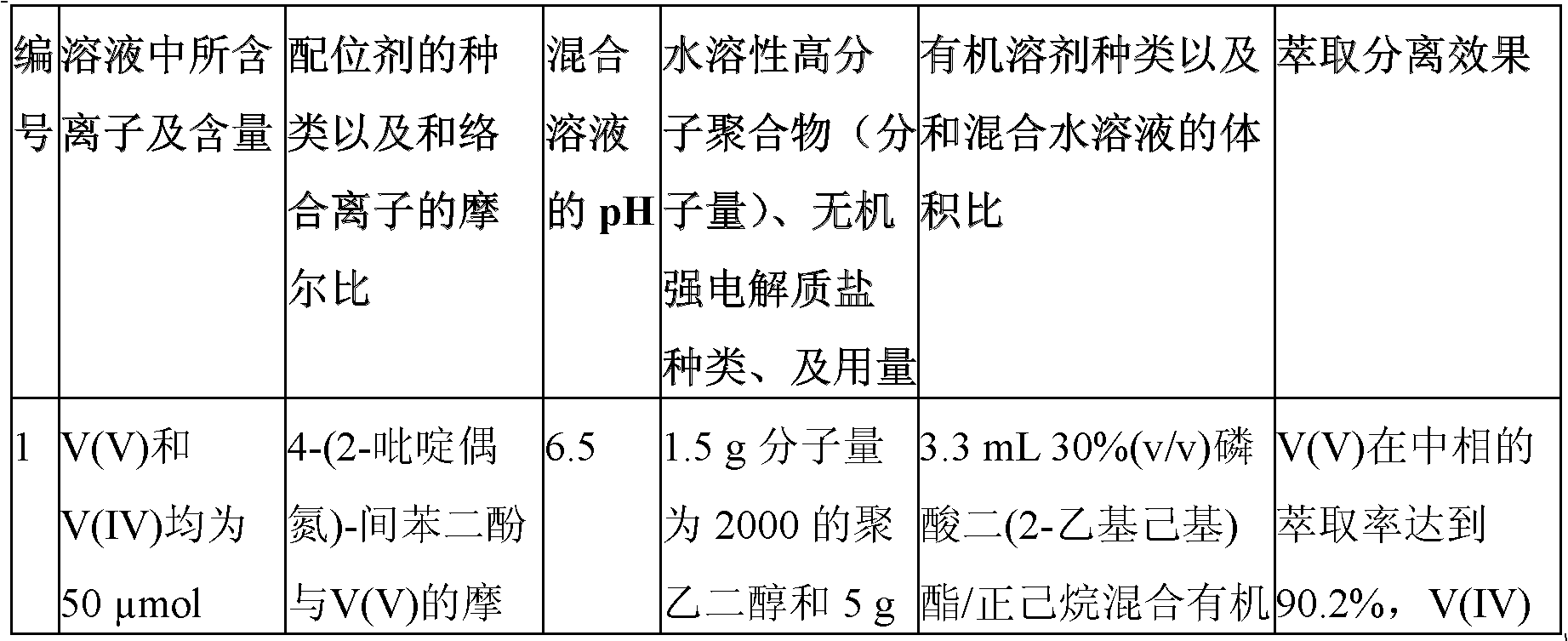

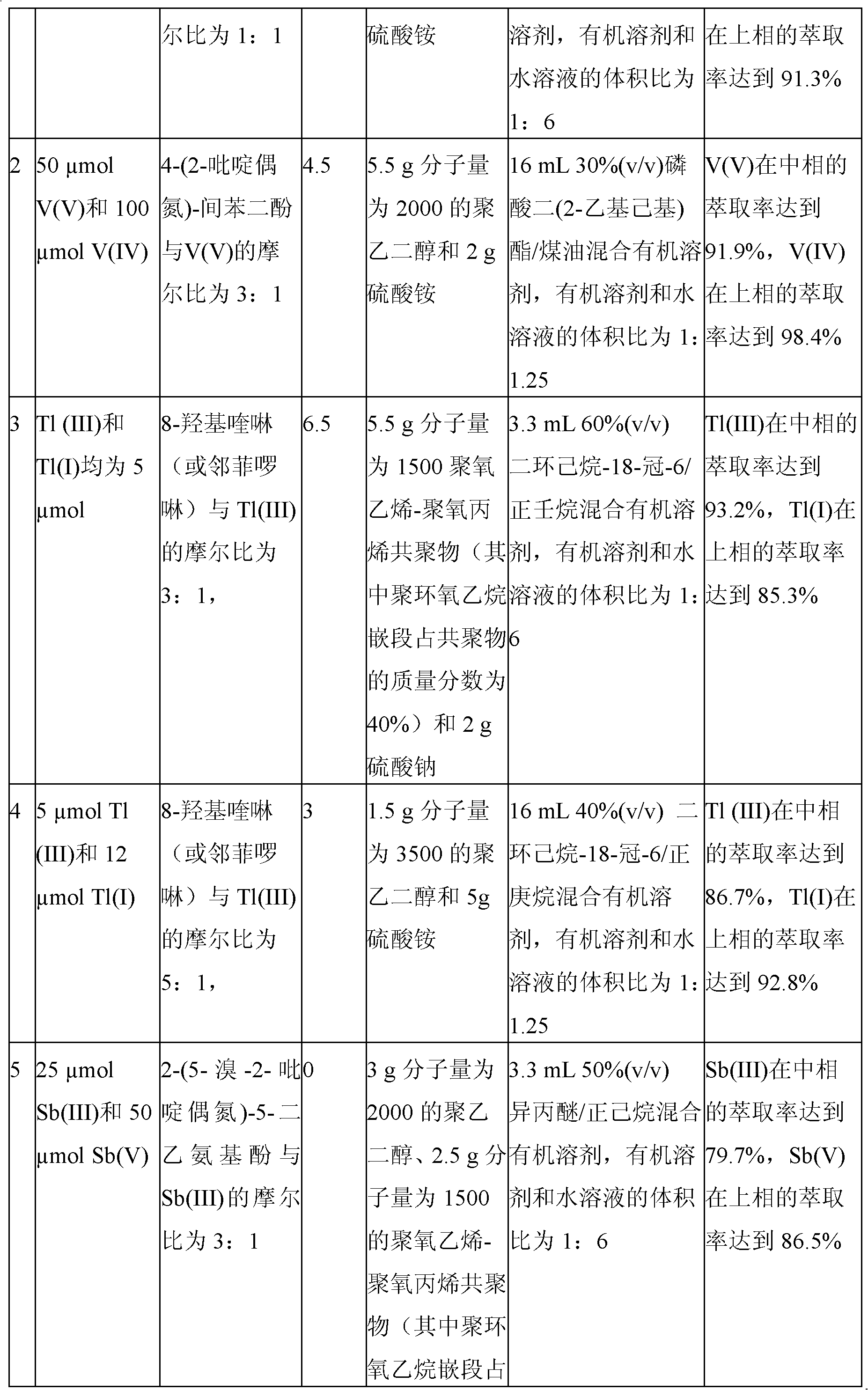

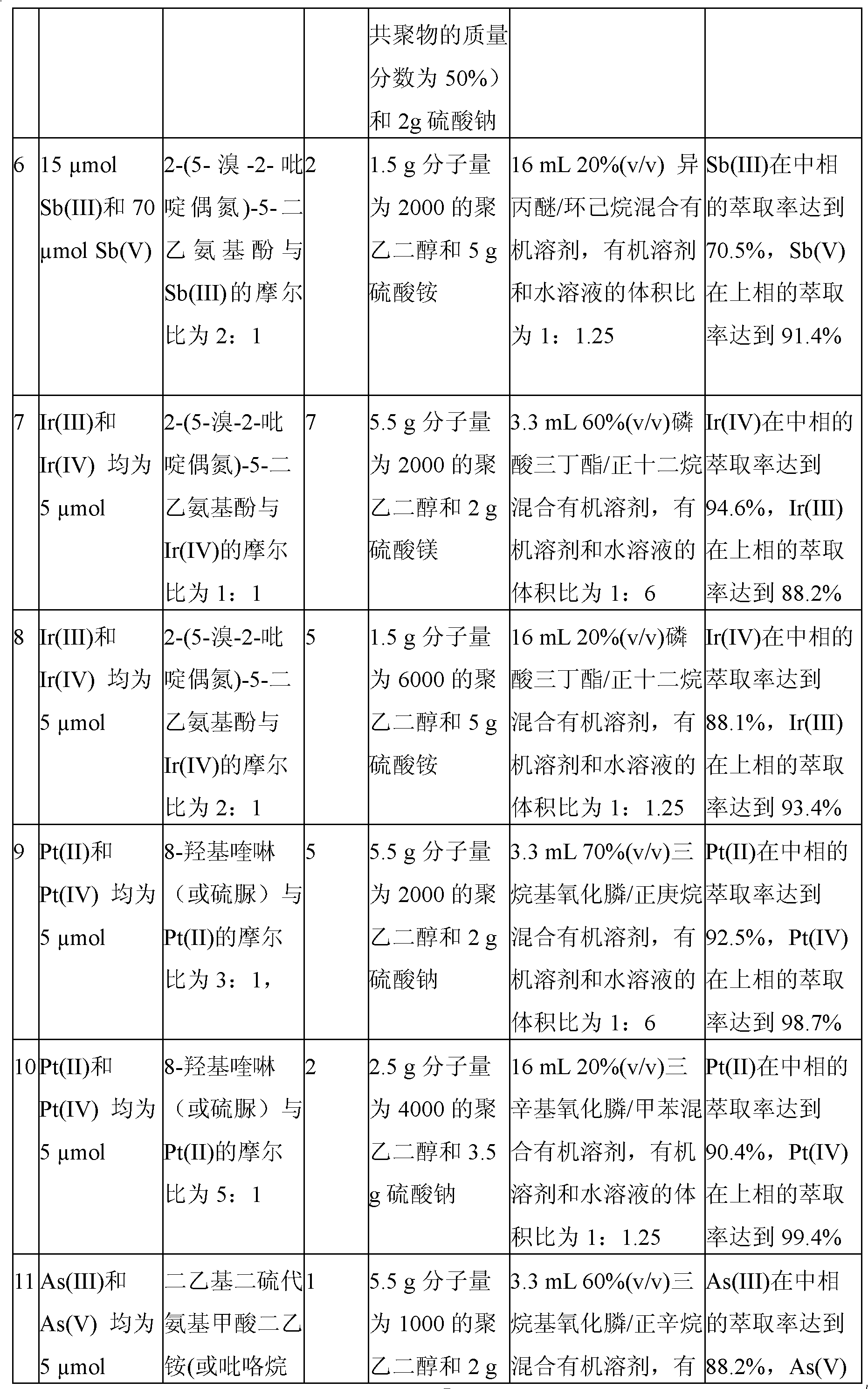

Examples

Embodiment 1

[0029]1.5 g of polyethylene glycol with a molecular weight of 2000 and 5 g of ammonium sulfate were dissolved in a solution containing 100 μmol of Cr(III) and Cr(VI), adjusted to pH=6 with sulfuric acid and sodium hydroxide, and adjusted to a volume of 20 mL, Then add 3.3 mL of 30% (v / v) bis(2-ethylhexyl) phosphate / n-hexane mixed organic solvent, the volume ratio of organic solvent and aqueous solution is 1:6, after shaking for 5 min, centrifuge at 3000 rpm for 10 min , forming a liquid-liquid-liquid three-phase system. The extraction rate of Cr(VI) in the polyethylene glycol middle phase reached 80.2%, and the extraction rate of Cr(III) in the upper phase reached 91.5%.

Embodiment 2

[0031] 5.5g molecular weight is 1500 polyoxyethylene-polyoxypropylene copolymers (wherein the polyethylene oxide block accounts for the mass fraction of copolymer is 40%) and 2g sodium sulfate dissolves in containing 150 μ mol Cr (III) and 100 μ mol Cr (VI ) solution, adjust the pH=3 with sulfuric acid and ammonia water, and set the volume to 20mL, then add 16mL of 30% (v / v) di(2-ethylhexyl) phosphate / kerosene mixed organic solvent, organic solvent and The volume ratio of the aqueous solution was 1:1.25. After shaking for 15 minutes, it was centrifuged at 3000 rpm for 8 minutes. At this time, a liquid-liquid-liquid three-phase system was formed. The extraction rate of Cr(VI) in the middle phase reaches 99.3%, and the extraction rate of Cr(III) in the upper phase reaches 60.6%.

Embodiment 3

[0033] 1.5g of polyethylene glycol with a molecular weight of 2000 and 5g of ammonium sulfate are dissolved in a solution containing 50 μmol of Fe(III) and Fe(II), and 150 μmol of o-phenanthroline is added, wherein the mole of o-phenanthroline and Fe(II) The ratio is 3:1, adjust pH=6 with sulfuric acid, and set the volume to 20mL, then add 8mL of 60% (v / v) trialkylphosphine oxide / n-dodecane mixed organic solvent, organic solvent and aqueous solution The volume ratio is 1:2.5. After shaking for 30 minutes, centrifuge at 3000 rpm for 10 minutes. At this time, a liquid-liquid-liquid three-phase system is formed. The extraction rate of Fe(II) in the polyethylene glycol middle phase reaches 99.5%, and the extraction rate of Fe(III) in the upper phase reaches 75.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com